Composite rubber as well as preparation method and application thereof

A technology of compounding rubber and polymerization reaction, applied in the rubber field, can solve the problems of high cost and rising cost of shoe materials, and achieve the effect of reducing price, saving process and saving process steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

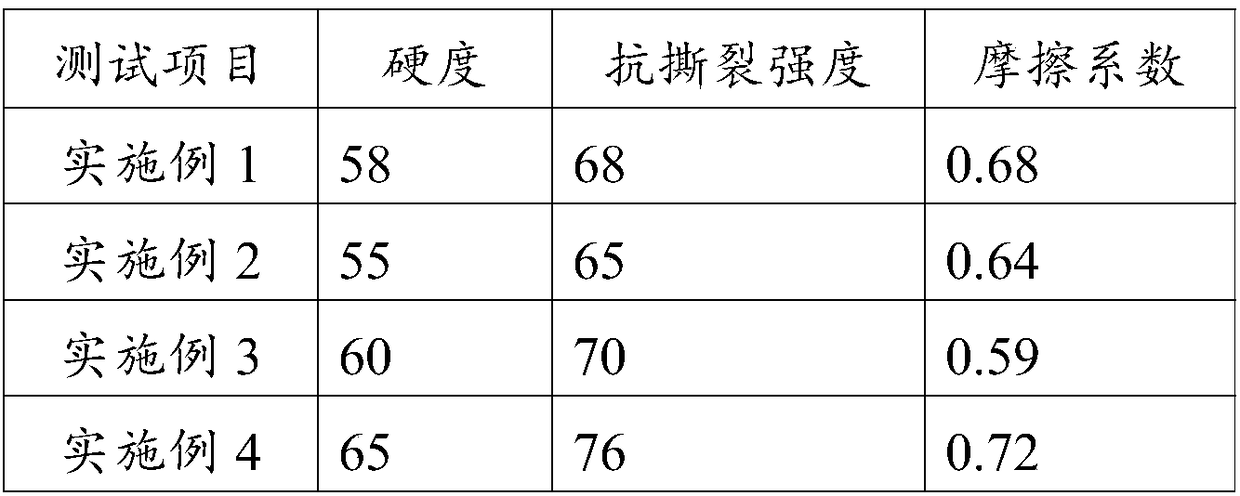

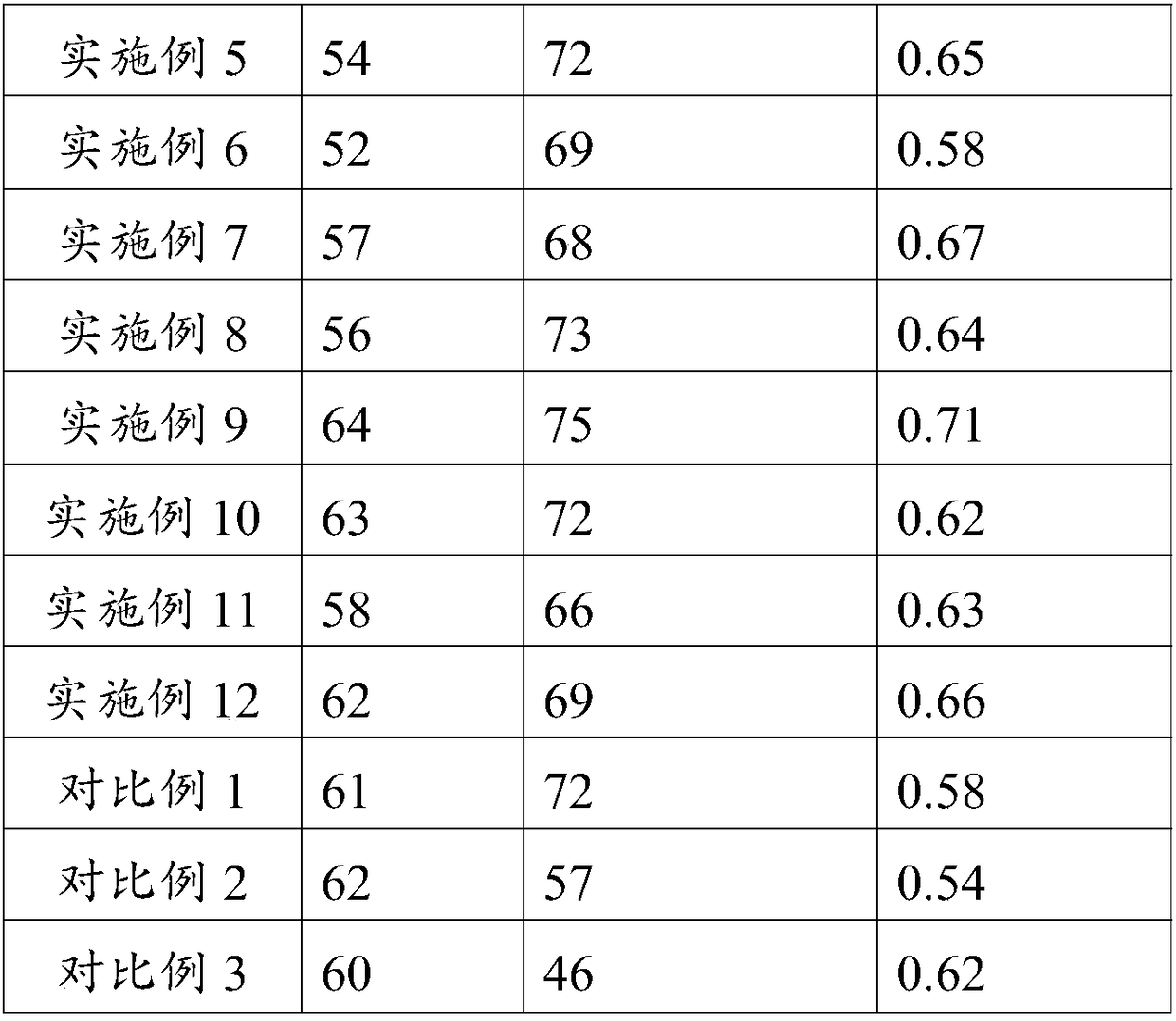

Examples

preparation example Construction

[0027] When the composite rubber is prepared by the preparation method provided by the invention, the process steps of plasticizing can be saved, and it only needs to be added before adding powder during compacting. The process has the advantages of simple process and process saving.

[0028] Pentene is a colorless, volatile, flammable liquid with a density of 0.6411, a melting point of -138°C, and a boiling point of 30°C. It is insoluble in water but soluble in ethanol. It will decompose into lower hydrocarbons at high temperature. It is used in organic synthesis and dehydrogenation to produce isoprene, which can be obtained by dehydrogenation of pentane.

[0029] Cyclopentadiene is a highly active alicyclic hydrocarbon with molecular formula C 5 h 6 , colorless liquid, melting point -97.542 ° C, boiling point 40 ° C, relative density 0.8021, exists in coal tar, easy to react with unsaturated compounds to generate a large number of cyclic compounds. Cyclopentadiene is also...

Embodiment 1

[0055] This embodiment is a kind of composite rubber, which includes the following raw materials by weight percentage: pentene 50%, cyclopentadiene 30% and dicyclopentadiene 20%.

[0056] The preparation method of the composite rubber includes the following steps: mixing pentene, cyclopentadiene and dicyclopentadiene, and performing a polymerization reaction, and obtaining the composite rubber after the reaction is completed. Wherein, the polymerization reaction temperature is 20°C.

Embodiment 2

[0058] This embodiment is a kind of composite rubber, which includes the following raw materials by weight percentage: 45% pentene, 35% cyclopentadiene and 20% dicyclopentadiene.

[0059] Wherein, the preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com