Formaldehyde-removing coating and preparation method thereof

A formaldehyde and paint technology, applied in the field of formaldehyde-removing paint and its preparation, can solve problems such as inability to decompose and remove formaldehyde, and achieve the effect of accelerating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Example 1: A formaldehyde-removing coating, which includes components and their corresponding parts by weight as shown in Table 1, and is prepared through the following steps:

[0038] S1: Add corresponding weight parts of mesoporous silicon and catalytic titanium dioxide into the paint stirring tank, and stir the mesoporous silicon and catalytic titanium dioxide evenly at a speed of 500 rpm;

[0039] S2: Add corresponding parts by weight of water-soluble hydroxyethyl cellulose, defoamer, silicone-based regulator and other components by corresponding parts by weight and stir at a speed of 500 rpm for ten minutes;

[0040] S3: Add toning titanium dioxide for toning, diatomaceous earth and heavy calcium carbonate and stir at a speed of 1250 rpm for 30 minutes;

[0041] S4: Add the anti-freeze-thaw stabilizer and defoamer of corresponding weight parts and stir at a speed of 1000 rpm for five minutes, and observe the elimination of bubbles during the stirring process;

[0...

Embodiment 2-9

[0046] Embodiment 2-9: A formaldehyde paint, the difference from Embodiment 1 is that the components included therein and their corresponding parts by weight are shown in Table 1.

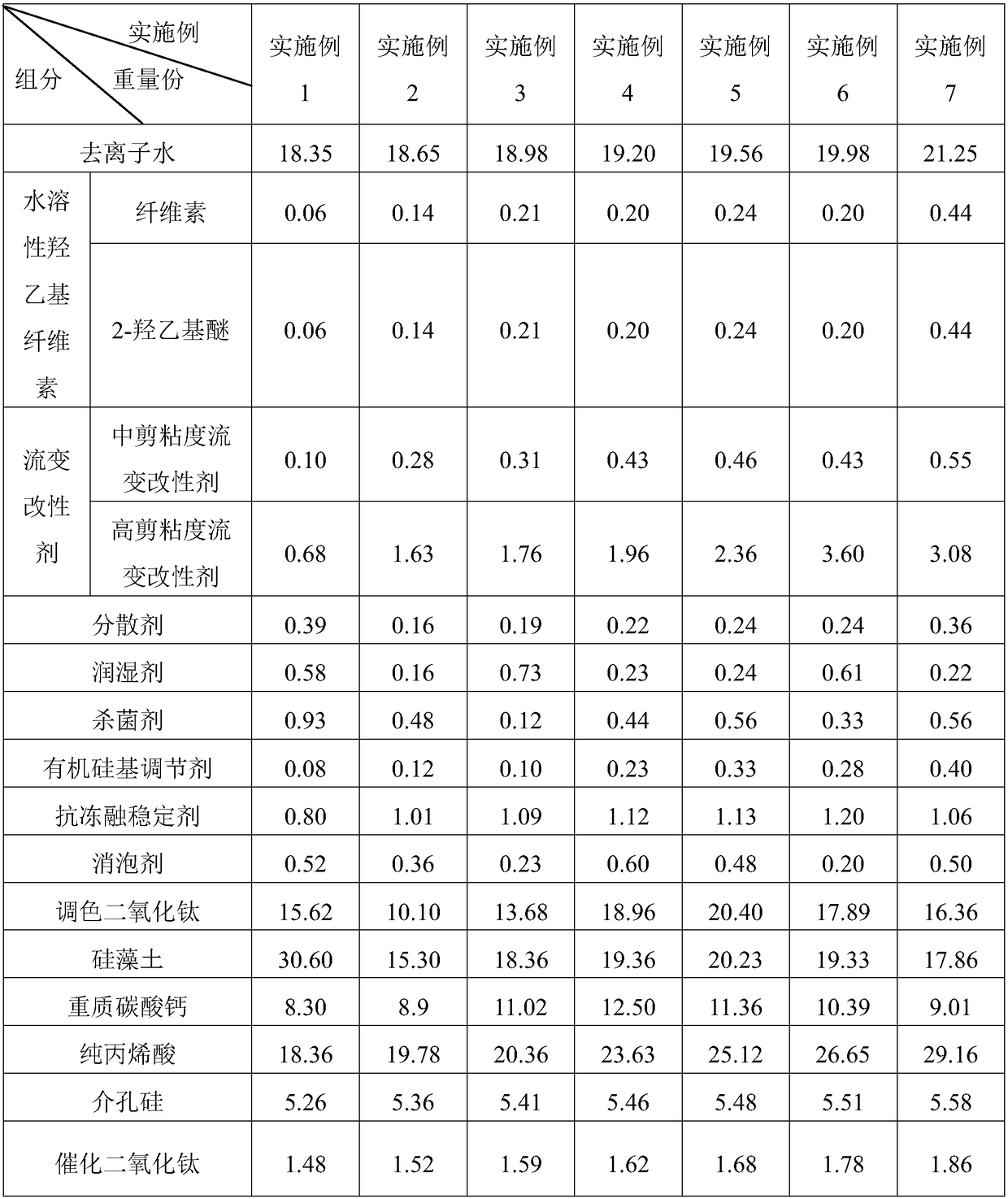

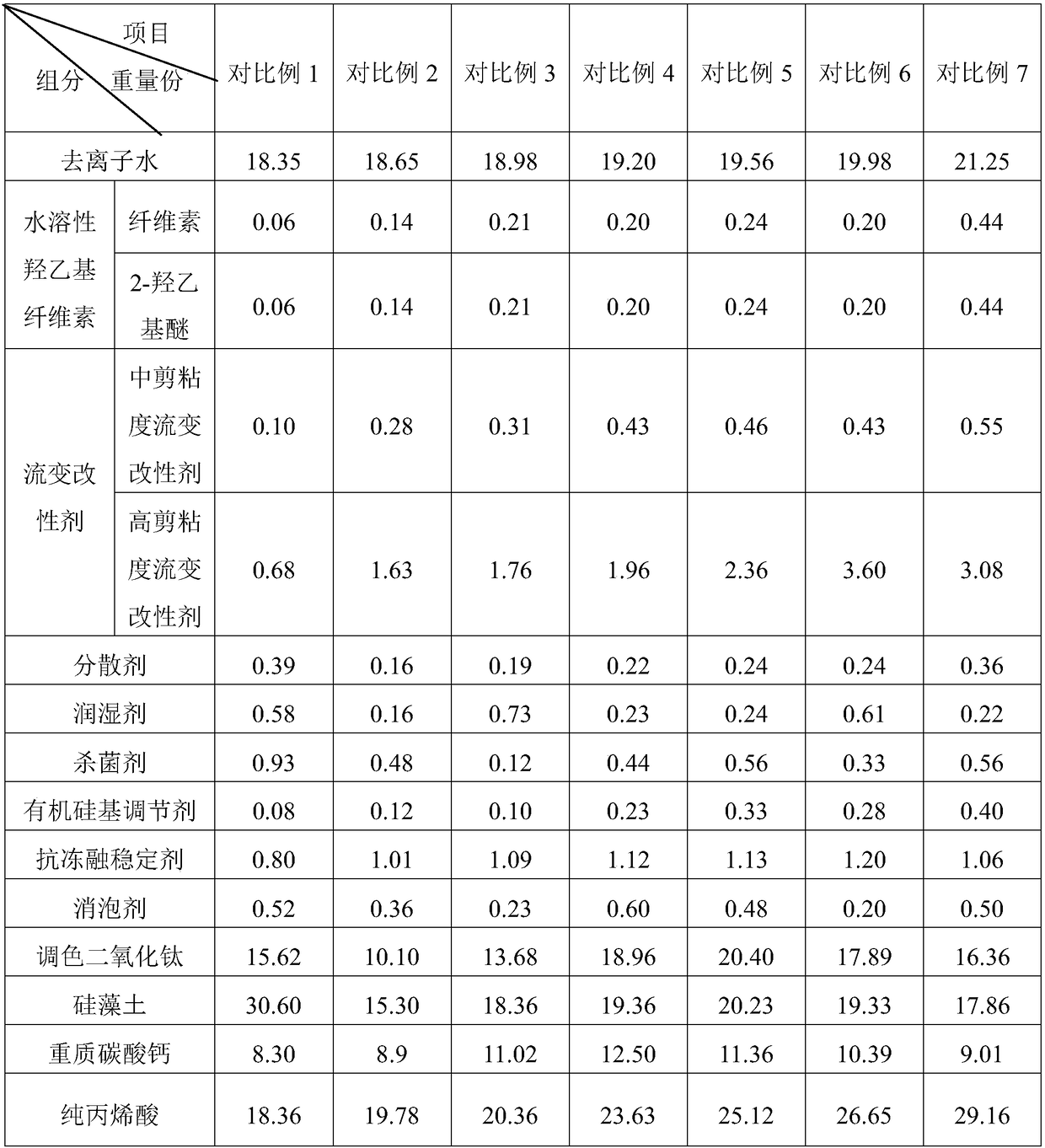

[0047] Components and their corresponding parts by weight in table 1, embodiment 1-7

[0048]

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com