Cutting fluid regeneration system

A regeneration system and cutting fluid technology, applied in the direction of lubricating composition, etc., can solve the problems of inability to be directly reused, increase production costs, environmental pollution, etc., achieve good results, reduce environmental pollution, and reduce production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

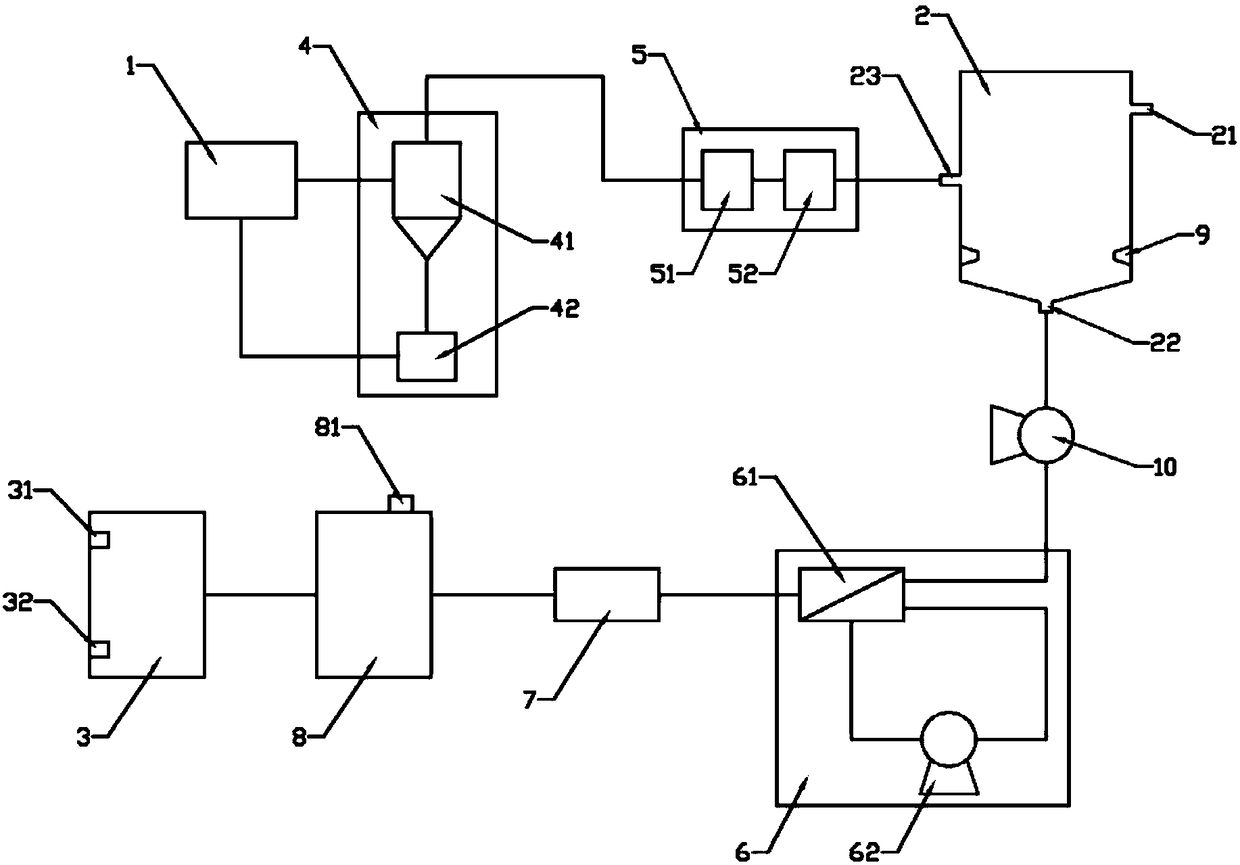

[0015] Such as figure 1 As shown, in this embodiment, the present invention includes a waste liquid tank 1, an intermediate water tank 2, and a liquid storage tank 3, and the waste liquid tank 1, the intermediate water tank 2, and the liquid storage tank 3 are sequentially connected by pipelines, so that Between the waste liquid tank 1 and the intermediate water tank 2, a solid-liquid separation module 4 and a filter module 5 are sequentially arranged, and between the intermediate water tank 2 and the liquid storage tank 3, a debris circulation processing module 6, Sterilization module 7 and regeneration tank 8, the sundries circulation processing module 6 includes a special film 61 arranged on the pipeline and a circulation pump 62 matched with the special film 61, the regeneration tank 8 is provided with additives Dosing device 81. In this design, the solid-liquid separation module 4 and the filtration module 5 can filter out chips and iron powder in the cutting waste liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com