Laser conduction device

A transmission device and laser technology, applied in the field of laser lighting, can solve the problems of poor assembly flexibility and high hardware manufacturing cost of laser integrated headlights, and achieve the effect of increasing the irradiation distance, enhancing the flexibility of assembly and modification, and uniform distribution of light spots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

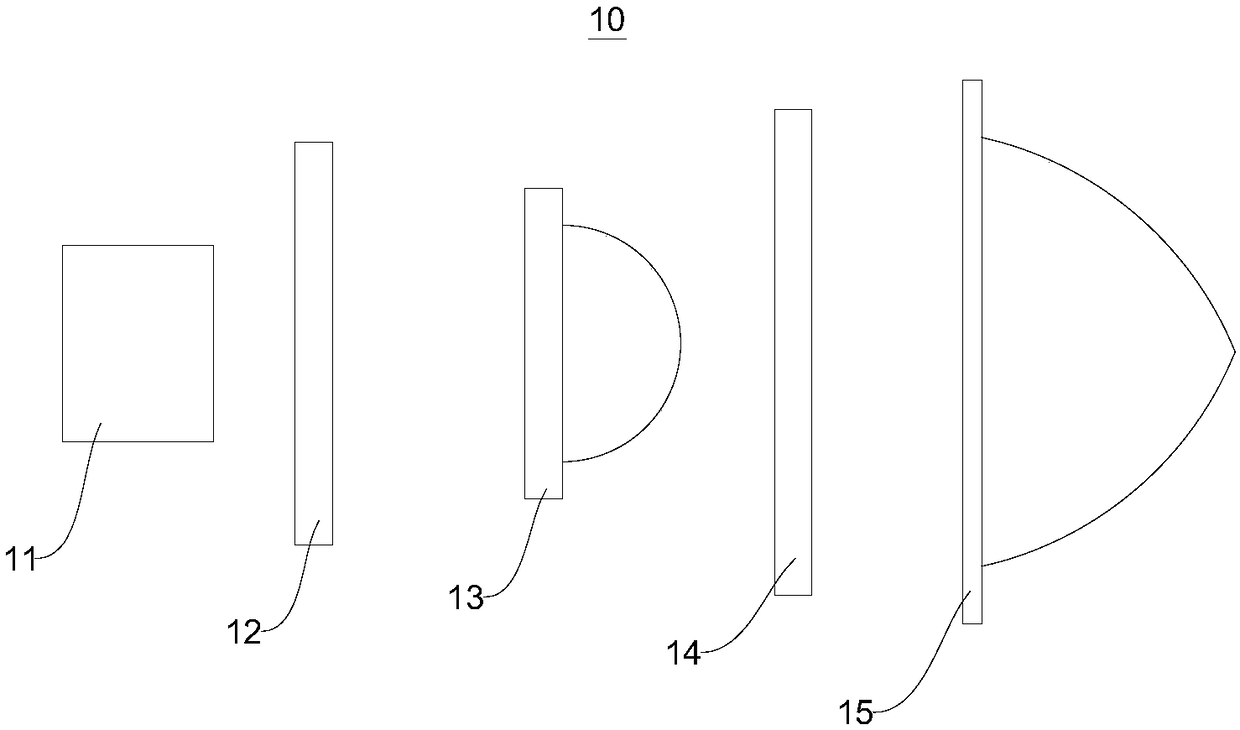

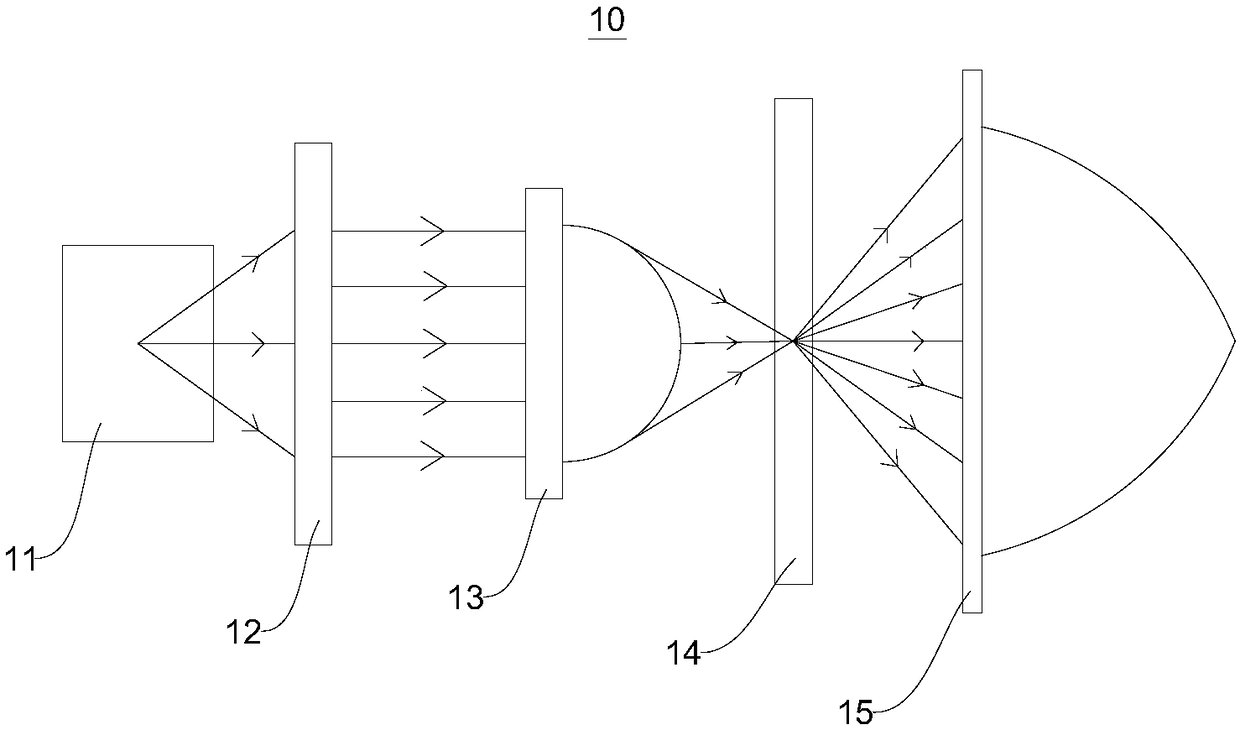

[0034] Please refer to figure 1 with figure 2 , figure 1 It is a schematic diagram of the assembly structure of a laser transmission device provided in the first embodiment of the present invention, figure 2 It is a schematic diagram of optical path transmission of a laser transmission device provided in the first embodiment of the present invention.

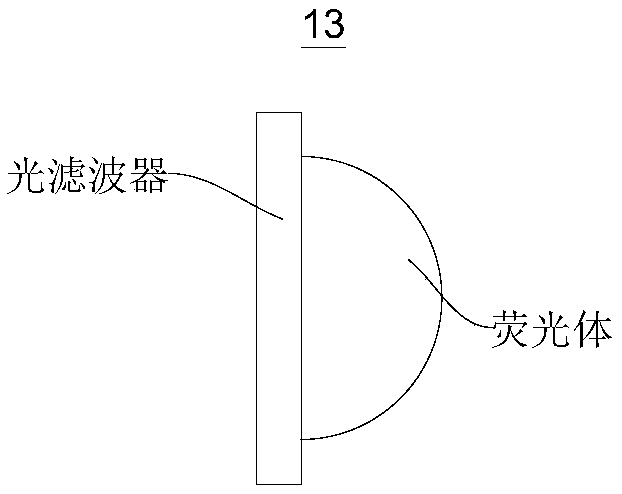

[0035] The laser transmission device 10 includes a laser light source 11 , a polygon mirror 12 , a focusing lens 13 , a fluorescence conversion device 14 and a beam shaper 15 .

[0036] As an embodiment, the laser light source 11, the polygon mirror 12, the focusing lens 13, the fluorescent conversion device 14 and the beam shaper 15 are all on the same straight line, so as to simplify the structure of the laser transmission device 10 and reduce the weight of the laser transmission device 10. volume.

[0037] The laser light source 11 is an electric light source that uses excited particles to emit light under the action of...

no. 2 example

[0051] The second embodiment of the present invention provides a constant current laser conduction device 20. The difference between the constant current laser conduction device 20 and the laser conduction device 10 provided in the first embodiment of the present invention is that in order to protect the fragile semiconductor laser array, To avoid damage to the semiconductor laser array caused by voltage fluctuations and temperature changes, the constant current laser transmission device 20 further includes a constant current laser controller 21 connected to the laser light source 11 .

[0052] Please refer to Figure 4 , Figure 4 It is a schematic diagram of the connection between a constant current laser controller and a laser light source provided by the second embodiment of the present invention.

[0053] The constant current laser controller 21 is connected to the laser light source 11 , and the power supply supplies power to the laser light source 11 under the control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com