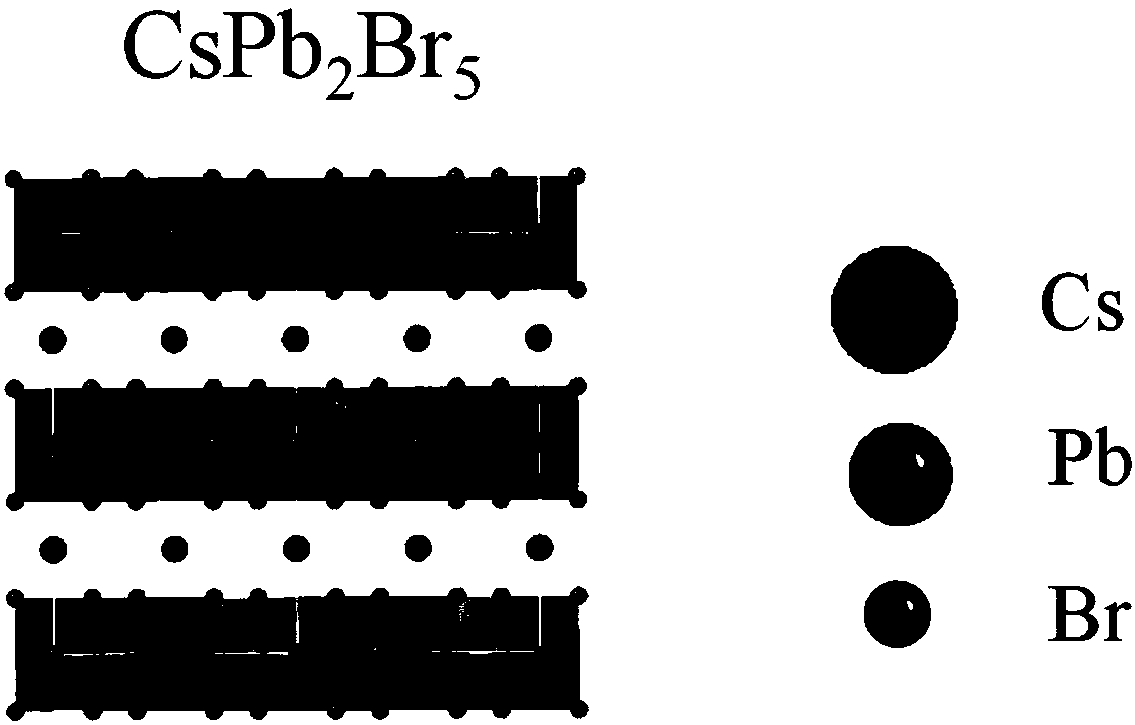

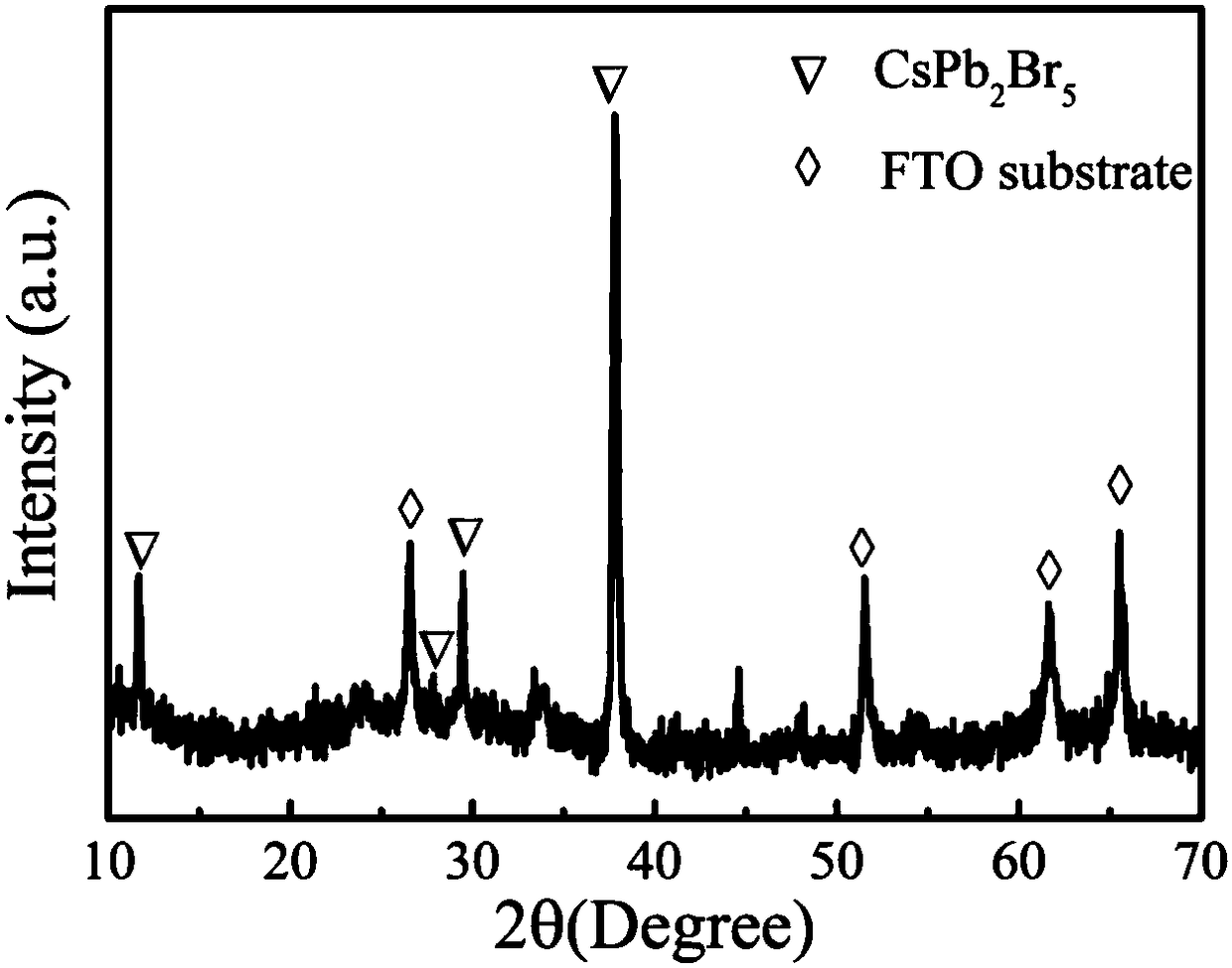

Preparation method of two-dimensional inorganic perovskite anode material for lithium battery

A negative electrode material, inorganic calcium technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of high cost and complex preparation process, and achieve the effect of good stability and excellent physical and chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A method for preparing a two-dimensional inorganic perovskite negative electrode material for a lithium battery, comprising the following steps:

[0026] S1. Add lead bromide and cesium bromide in a molar ratio of 2:1 to N,N-dimethylformamide, heat to 68°C, and stir for 3 hours. Nitrogen gas is introduced during the stirring process to obtain a mixed material;

[0027] S2. Vacuum drying the mixed material for 11 hours at a vacuum drying temperature of 82° C. to obtain a white precursor material;

[0028] S3. Add the precursor material to toluene, centrifuge three times, and vacuum-dry the solid obtained by centrifugation for 1.5 hours at a temperature of 72° C. to obtain a two-dimensional inorganic perovskite negative electrode material for lithium batteries.

Embodiment 2

[0030] A method for preparing a two-dimensional inorganic perovskite negative electrode material for a lithium battery, comprising the following steps:

[0031] S1. Add lead bromide and cesium bromide in a molar ratio of 2:1 to N,N-dimethylformamide, heat to 72°C, stir for 2 hours, and inject argon gas during the stirring process to obtain a mixed material;

[0032] S2. Vacuum drying the mixed material for 13 hours at a vacuum drying temperature of 78° C. to obtain a white precursor material;

[0033] S3. Add the precursor material to toluene, centrifuge three times, and vacuum-dry the solid obtained by centrifugation for 2.5 hours at a temperature of 68° C. to obtain a two-dimensional inorganic perovskite negative electrode material for lithium batteries.

Embodiment 3

[0035] A method for preparing a two-dimensional inorganic perovskite negative electrode material for a lithium battery, comprising the following steps:

[0036] S1. Put lead bromide and cesium bromide in a three-neck beaker with a molar ratio of 2:1, add 1mL N,N-dimethylformamide, heat to 70°C, stir for 2.5h, and add A mixed gas of nitrogen and neon is used to avoid the influence of humidity in the air to obtain a mixed material;

[0037] S2. Pour the mixed material into a clean beaker, place it in a vacuum drying oven, the vacuum drying temperature is 80° C., and the vacuum drying time is 12 hours to obtain a white precursor material;

[0038] S3. Add the precursor material to toluene, centrifuge three times, and vacuum-dry the solid obtained by centrifugation for 2 hours at a temperature of 70° C. to obtain a two-dimensional inorganic perovskite negative electrode material for lithium batteries.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com