Online continuous production preparation method for concentric continuous oil pipe

A technology of oil pipe and outer pipe, which is applied in the field of online continuous production and preparation of concentric coiled tubing, which can solve problems such as easy springback, difficulty in fixing, and complicated implementation process, and achieve the effect of reducing production costs and saving pipe penetration costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

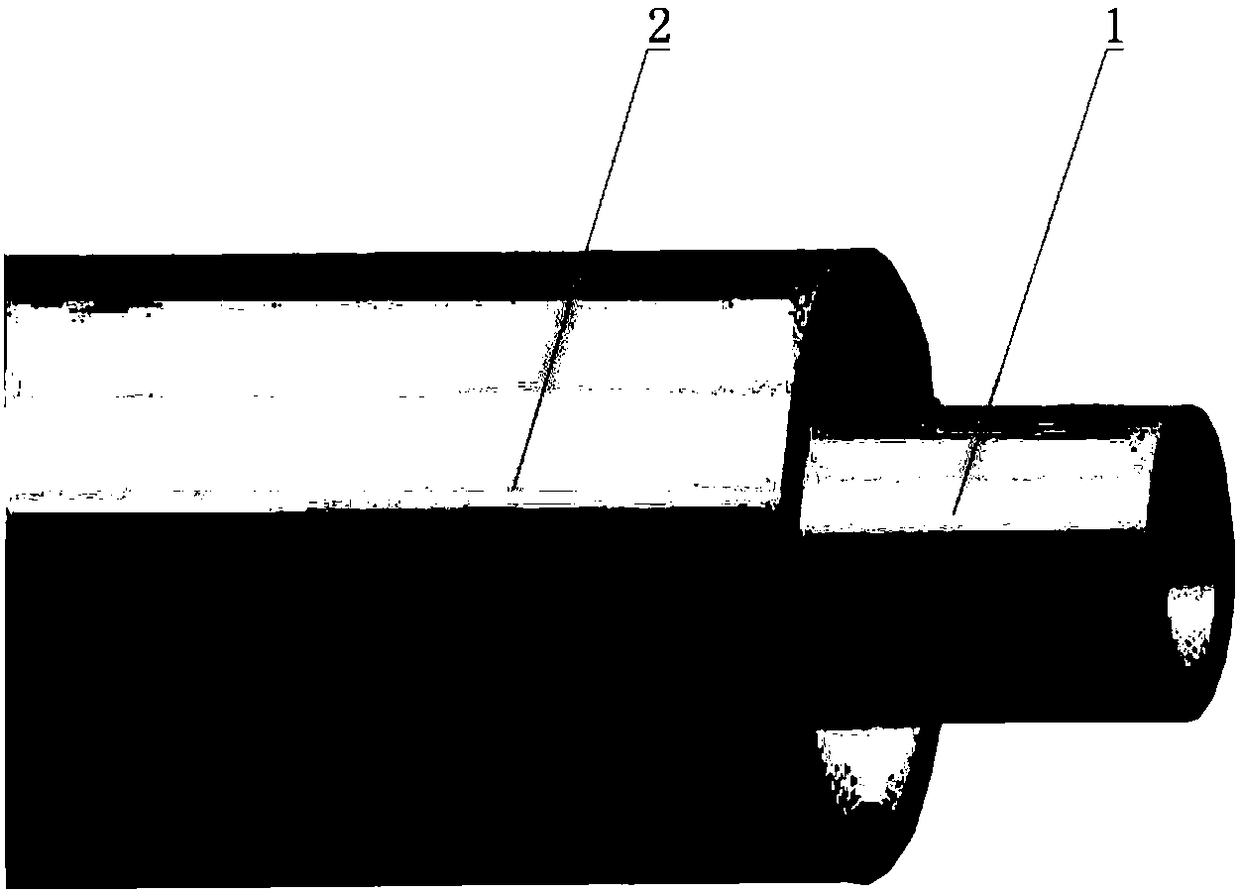

[0035] A specific example of piercing a 4500m long CT80 steel grade inner pipe 1 with a length of 25.4mm*1.9mm into a corresponding CT80 steel grade outer pipe 2 with a length of 50.8mm*2.8mm.

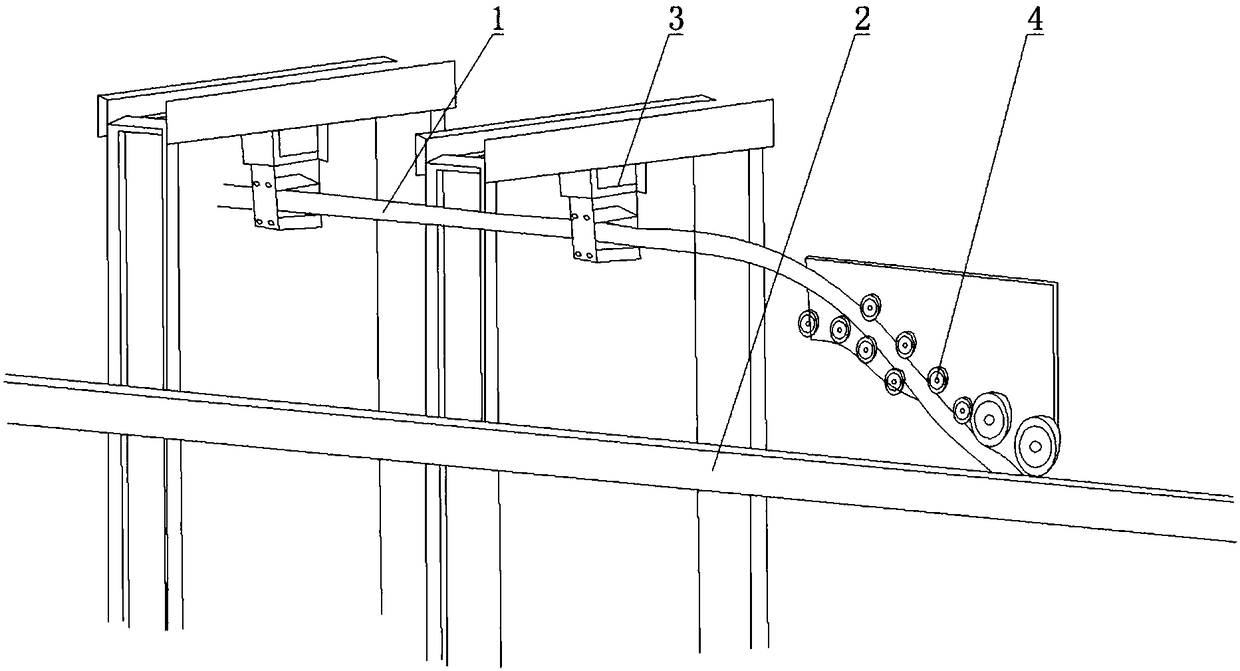

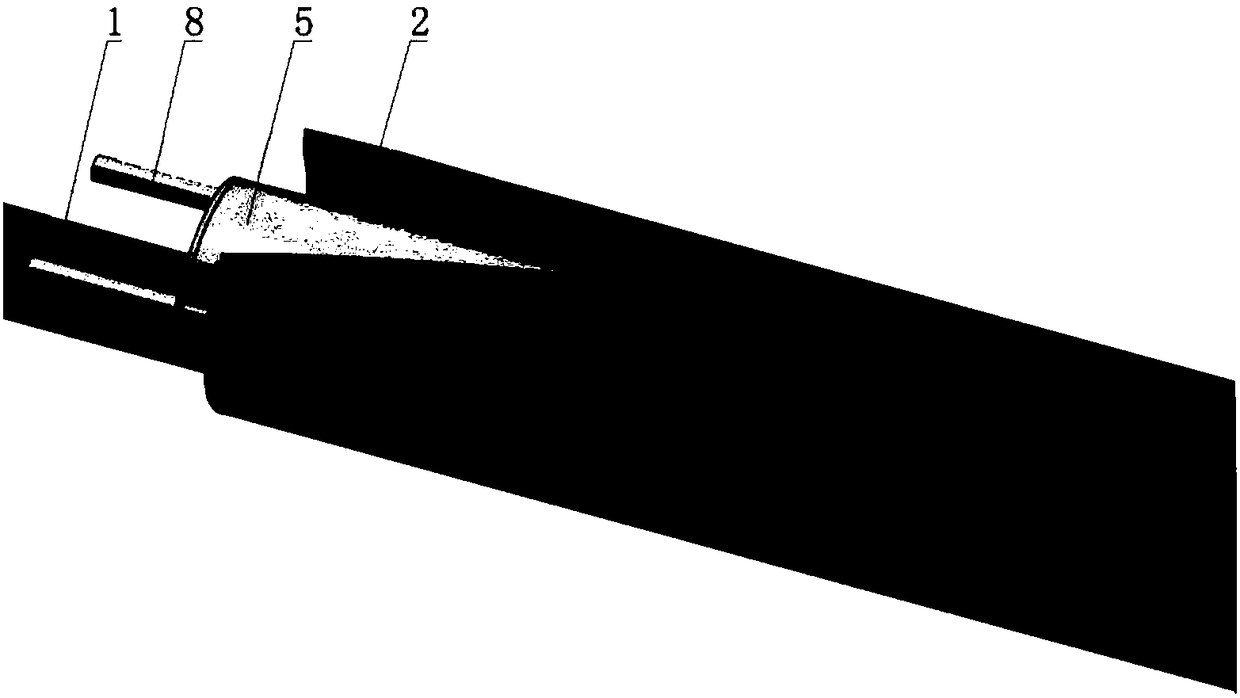

[0036]The prepared inner tube 1 (25.4mm*1.9mm) is wound on the production drum, and it enters the guide frame 3 horizontally through the pipe inversion device, and enters the guide curved rail 4 through the guide frame 3 (curvature radius 2.5 m), after two times of bending in the curved guide rail 4, the inner tube 1 extends horizontally into the outer tube 2 (50.8mm*2.8mm) before crimping. After the inner pipe 1 is inserted into the outer pipe 2, the inner pipe 1 is welded to the bottom of the outer pipe 2, and the welding length is 1m. Adjust the inner tube 1 production drum and pipe inverter so that the speed at which the inner tube 1 penetrates into the outer tube 2 matches the production speed (20m / min) of the outer tube 2 high-frequency induction welding. With the production of t...

Embodiment 2

[0038] A specific example of piercing a 5000m long CT90 steel grade inner pipe 1 with a length of 25.4mm*2.1mm into a corresponding CT90 steel grade outer pipe 2 with a length of 50.8mm*2.8mm.

[0039] The prepared inner tube 1 (25.4mm*2.1mm) is wound on the production drum, and it enters the guide frame 3 horizontally through the pipe inversion device, and enters the guide curved rail 4 through the guide frame 3 (the radius of curvature is 2.5 m), after two times of bending in the curved guide rail 4, the inner tube 1 extends horizontally into the outer tube 2 (50.8mm*2.8mm) before crimping. After the inner pipe 1 is inserted into the outer pipe 2, the inner pipe 1 is welded to the bottom of the outer pipe 2, and the welding length is 1m. Adjust the inner tube 1 production roller and pipe inverter so that the speed at which the inner tube 1 penetrates the outer tube 2 matches the production speed (15m / min) of the outer tube 2 high-frequency induction welding. With the product...

Embodiment 3

[0041] A specific example of piercing a 3600m long CT80 steel grade inner pipe 1 with a length of 31.8mm*2.4mm into a corresponding CT80 steel grade outer pipe 2 with a length of 60.3mm*2.8mm.

[0042] The prepared inner tube 1 (31.8mm*2.4mm) is wound on the production drum, and it enters the guide frame 3 horizontally through the pipe inversion device, and enters the guide curved rail 4 through the guide frame 3 (the radius of curvature is 3m ), after two times of bending in the guide curved rail 4, the inner tube 1 horizontally extends into the outer tube 2 (60.3mm*2.8mm) before crimping. After the inner pipe 1 is inserted into the outer pipe 2, the inner pipe 1 is welded tightly to the bottom of the outer pipe 2, and the welding length is 1.5m. Adjust the inner tube 1 production drum and pipe inverter so that the speed at which the inner tube 1 penetrates into the outer tube 2 matches the production speed (13m / min) of the outer tube 2 high-frequency induction welding. As th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com