Production technology for producing cyclohexyl formate by dividing wall reaction rectification

A technology of cyclohexyl formate and reactive distillation, which is applied in the field of production technology of cyclohexyl formate by reactive distillation next door, can solve the problems of low yield, high energy consumption, complicated process, etc., and achieve reduction of production equipment, purity High, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

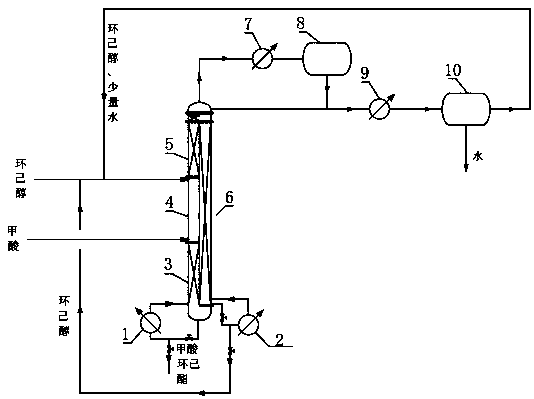

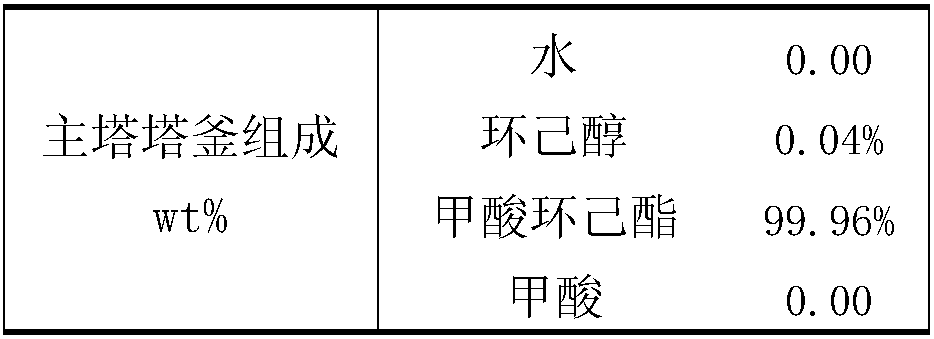

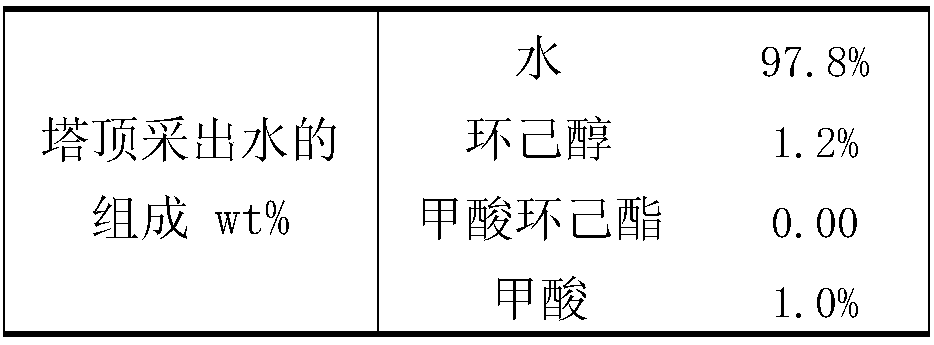

[0024] A production process for producing cyclohexyl formate by reactive distillation in a partition, comprising the following steps:

[0025] (1) add the hexamethylene formate, 25% cyclohexanol, 25% formic acid that the percentage by weight is 50% in the main rectification tower still of next door reactive distillation column, add hexamethylene alcohol in the secondary rectification tower still, The liquid levels of the two towers and kettles both reached 70%, and a certain amount of zeolite was added to the tower kettles of the main rectifying tower and the auxiliary rectifying tower to prevent bumping, and the reboiler Ⅰ1 and reboiler Ⅱ2 were turned on, and the electric heating wire switch was turned on Carry out heat preservation, control the pressure in the reaction rectifying column next door to be 15kPa;

[0026] (2) When the temperature of the main rectifying tower still reaches 100°C, add formic acid to the feed port at the lower end of reaction section 4, and simulta...

Embodiment 2

[0033] A production process for producing cyclohexyl formate by reactive distillation in a partition, comprising the following steps:

[0034] (1) add the hexamethylene formate, 25% cyclohexanol, 25% formic acid that the percentage by weight is 50% in the main rectification tower still of next door reactive distillation column, add hexamethylene alcohol in the secondary rectification tower still, The liquid levels of the two towers and kettles both reached 70%, and a certain amount of zeolite was added to the tower kettles of the main rectifying tower and the auxiliary rectifying tower to prevent bumping, and the reboiler Ⅰ1 and reboiler Ⅱ2 were turned on, and the electric heating wire switch was turned on Carry out heat preservation, control the pressure in the reaction rectifying column next door to be 10kPa;

[0035] (2) When the temperature of the main rectifying tower still reaches 90°C, add formic acid to the feed port at the lower end of reaction section 4, and simultan...

Embodiment 3

[0043] A production process for producing cyclohexyl formate by reactive distillation in a partition, comprising the following steps:

[0044] (1) add the hexamethylene formate, 25% cyclohexanol, 25% formic acid that the percentage by weight is 50% in the main rectification tower still of next door reactive distillation column, add hexamethylene alcohol in the secondary rectification tower still, The liquid levels of the two towers and kettles both reached 70%, and a certain amount of zeolite was added to the tower kettles of the main rectifying tower and the auxiliary rectifying tower to prevent bumping, and the reboiler Ⅰ1 and reboiler Ⅱ2 were turned on, and the electric heating wire switch was turned on Carry out heat preservation, control the pressure in the reaction rectifying column next door to be 15kPa;

[0045] (2) When the temperature of the main rectifying tower still reaches 90°C, add formic acid to the feed port at the lower end of reaction section 4, and simultan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com