New synthesis method for improving quality of thiophanate methyl

A technology of thiophanate-methyl and synthesis method, which is applied in the field of synthesis to improve the quality of thiophanate-methyl, can solve problems such as inability to increase the content, poor temperature control, unstable quality, etc., to reduce the generation of by-products, The effect of reducing the generation of pollutants and easy temperature control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

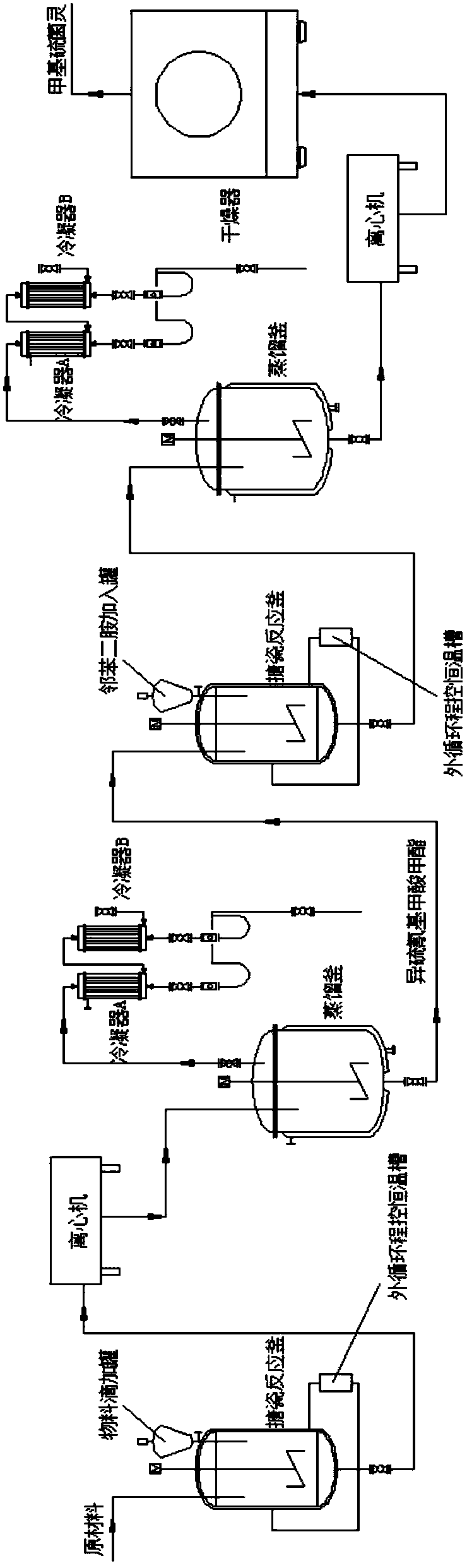

[0023] like figure 1 Shown, the technical scheme that the present invention adopts is: a kind of new synthetic method that improves the quality of thiophanate-methyl, and described synthetic method specifically comprises the following steps:

[0024] 1). Add ethyl acetate as a solvent to the enamel reaction kettle, then add sodium thiocyanate into the reaction kettle, control the reaction temperature at 59°C, start the mixer to stir, and quickly add methyl chloroformate dropwise to the inside of the reaction kettle Ester, methyl chloroformate and sodium thiocyanate react in the reactor. After the reaction stops, the reaction materials are filtered and centrifuged, and then the centrifugal liquid is subjected to vacuum distillation, and the low boiling point liquid is transferred to the inside of the reactor for circulation. reaction, the high boiling point liquid is methyl isothiocyanate;

[0025] The enamel reaction kettle in the step 1 is connected to the external circulati...

Embodiment 2

[0038] like figure 1 Shown, the technical scheme that the present invention adopts is: a kind of new synthetic method that improves the quality of thiophanate-methyl, and described synthetic method specifically comprises the following steps:

[0039] 1). Add ethyl acetate as a solvent to the enamel reaction kettle, then add sodium thiocyanate into the reaction kettle, control the reaction temperature at 50°C, start the mixer to stir, and quickly add methyl chloroformate dropwise to the inside of the reaction kettle Ester, methyl chloroformate and sodium thiocyanate react in the reactor. After the reaction stops, the reaction materials are filtered and centrifuged, and then the centrifugal liquid is subjected to vacuum distillation, and the low boiling point liquid is transferred to the inside of the reactor for circulation. reaction, the high boiling point liquid is methyl isothiocyanate;

[0040] The enamel reaction kettle in the step 1 is connected to an external circulatio...

Embodiment 3

[0053] like figure 1 Shown, the technical scheme that the present invention adopts is: a kind of new synthetic method that improves the quality of thiophanate-methyl, and described synthetic method specifically comprises the following steps:

[0054] 1). Add ethyl acetate as a solvent to the enamel reaction kettle, then add sodium thiocyanate into the reaction kettle, control the reaction temperature at 45°C, start the mixer to stir, and quickly add methyl chloroformate dropwise to the inside of the reaction kettle Ester, methyl chloroformate and sodium thiocyanate react in the reactor. After the reaction stops, the reaction materials are filtered and centrifuged, and then the centrifugal liquid is subjected to vacuum distillation, and the low boiling point liquid is transferred to the inside of the reactor for circulation. reaction, the high boiling point liquid is methyl isothiocyanate;

[0055] The enamel reaction kettle in the step 1 is connected to the external circulati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com