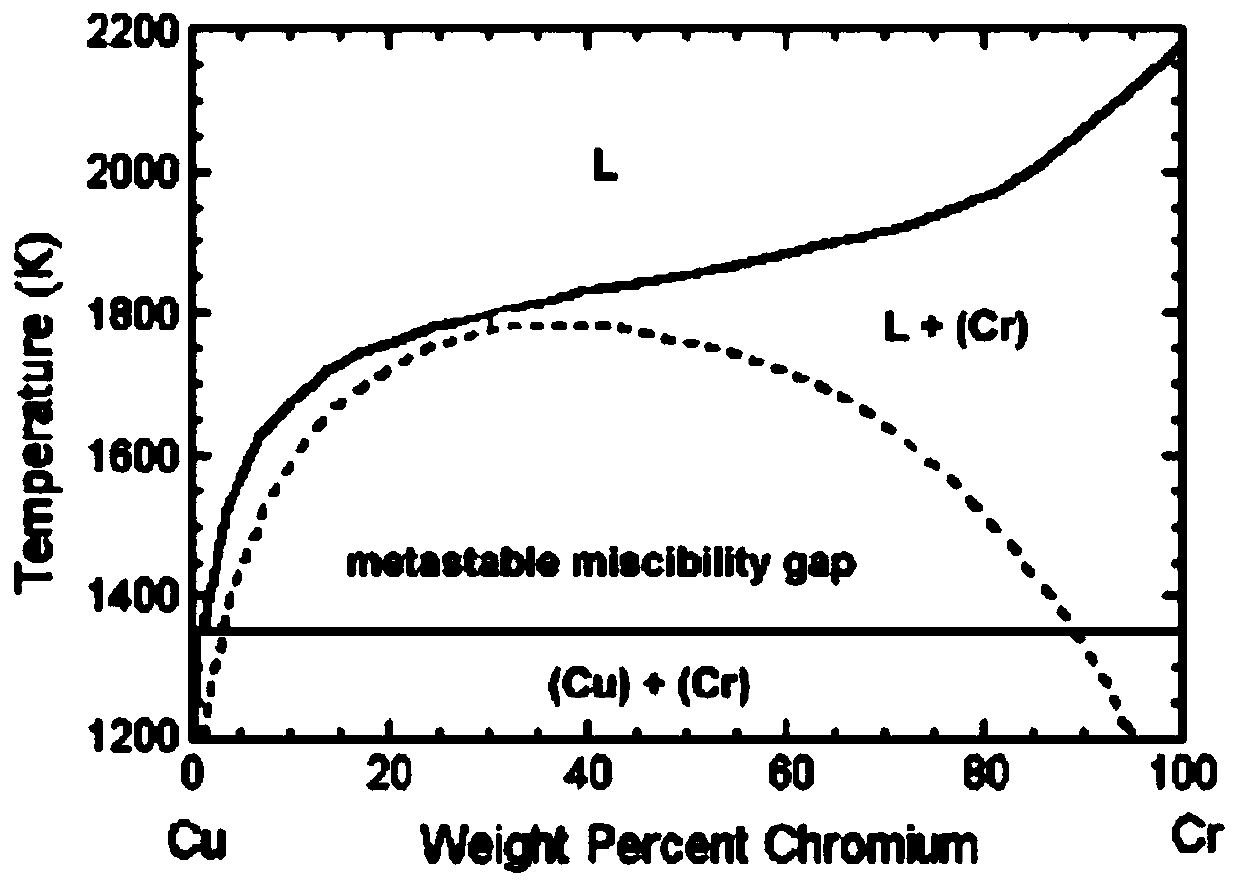

A kind of solidification preparation method of cu-cr electric contact alloy

An electrical contact, cu-cr technology, applied in the direction of contacts, circuits, electrical switches, etc., can solve the problems of alloy difficulty, phase segregation, two-phase delamination, etc., and achieve the effect of improving the nucleation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Such as image 3 Cu-10wt%Cr alloy and Cu-10wt%Cr-0.05wt%TiB were cast using copper molds as shown 2 alloy, the inner diameter of the copper mold is 5mm, and the temperature of the copper mold is room temperature before pouring. No TiB added 2 The Cr-rich phase exists in the form of coarse dendrites in the particle sample, and the addition of TiB 2 The Cr-rich phase exists in the form of fine particles in the alloy sample of particles, and the distribution is uniform.

[0025] Its preparation process is as follows:

[0026] Melting Cu-10wt%Cr Alloy and Cu-10wt%Cr-0.05wt%TiB by Electric Arc Furnace 2 Alloy, heat up to 1600°C and keep it warm for 2 minutes, then pour the melt into the copper mold.

Embodiment 2

[0028] Such as Figure 4 Cu-20wt%Cr alloy and Cu-20wt%Cr-0.05wt%TiB were cast using copper molds as shown 2 alloy, the inner diameter of the copper mold is 5mm, and the temperature of the copper mold is room temperature before pouring. No TiB added 2 The Cr-rich phase exists in the form of coarse dendrites in the particle sample, and the addition of TiB 2 The Cr-rich phase exists in the form of dispersed particles in the alloy sample of particles, and the distribution is uniform.

[0029] Its preparation process is as follows:

[0030] Melting Cu-20wt%Cr Alloy and Cu-20wt%Cr-0.05wt%TiB by Electric Arc Furnace 2 Alloy, heat up to 1600°C and keep it warm for 2 minutes, then pour the melt into the copper mold.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com