Assembly and construction process of steel skeleton light roof

A construction technique and steel skeleton technology, applied to roofs, roof coverings, and roofs using flat/curved panels, etc., can solve problems that affect building waterproofing, rainproof performance, living and use, and large roof joints, etc., to achieve The effect of shortening the construction process time, improving the waterproof level, and reducing assembly errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

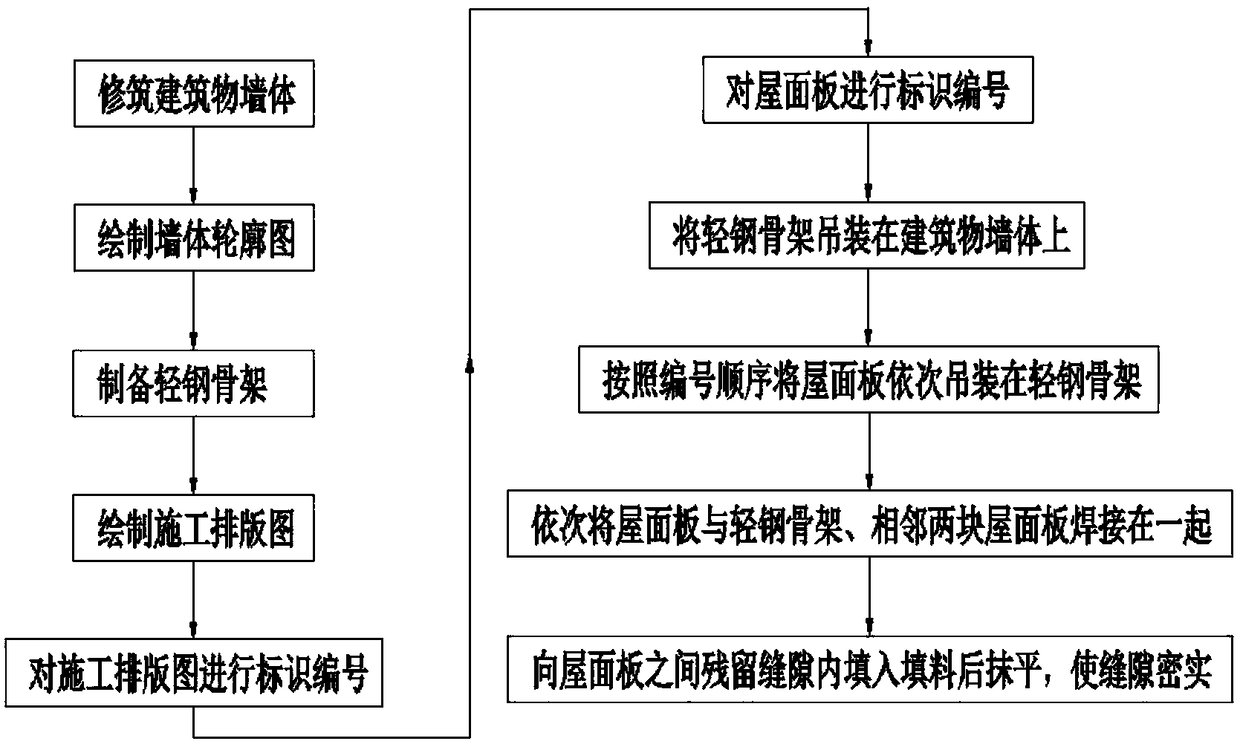

[0034] Such as figure 1 , figure 2 As shown, the present invention provides a kind of assembly construction technology of steel frame light roof, comprising the following steps:

[0035] Step 1: building a building wall on the ground so that the building wall forms a definite shape on the ground;

[0036] Step 2: Use a measuring tool to measure the outer contour of the shape enclosed by the building wall described in step 1, and draw a wall contour map according to the corresponding scale according to the measurement results;

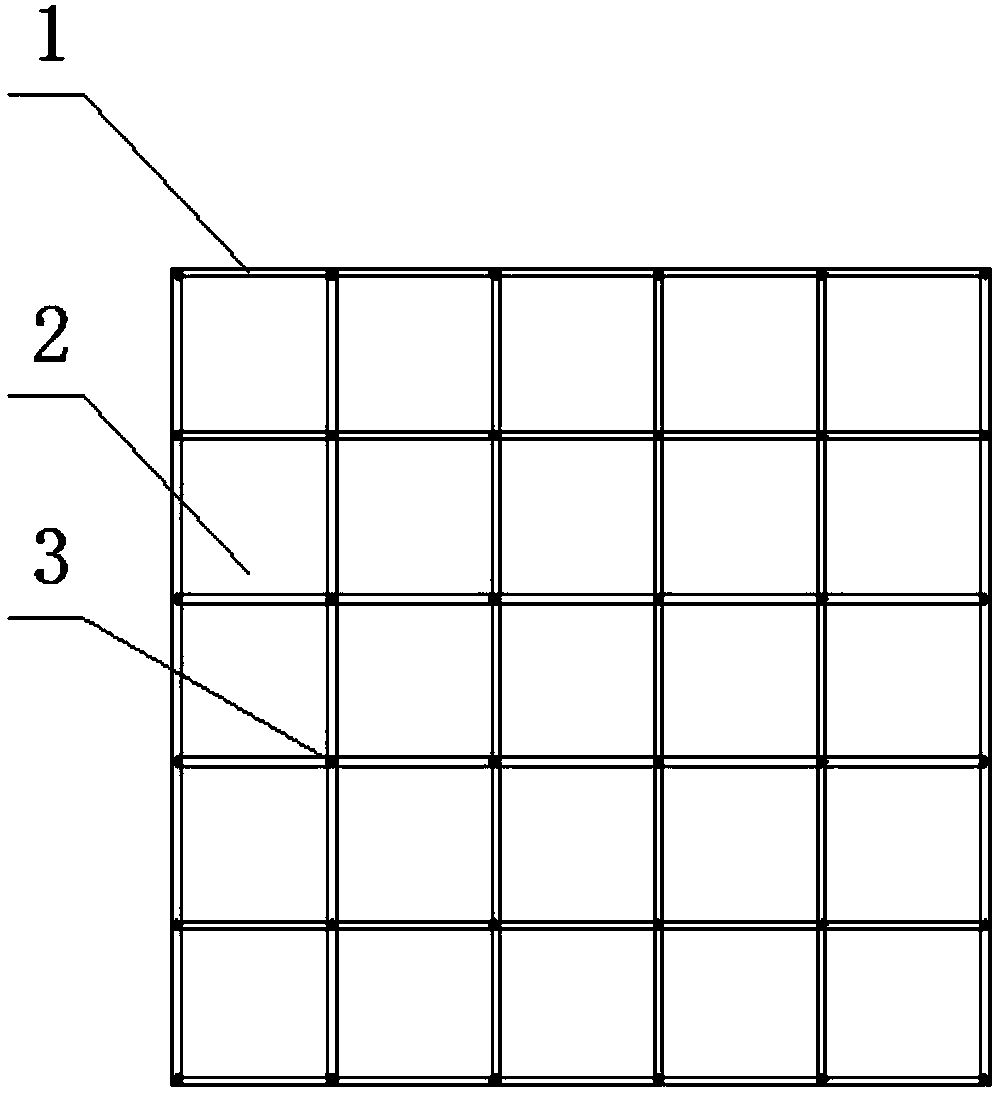

[0037] Step 3: Use metal materials to make multiple vertical keels, multiple horizontal keels, and multiple cylindrical supports. In the same plane, place all vertical keels in parallel at appropriate intervals, and then place all horizontal keels Place them in parallel according to the appropriate spaci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com