Compound micro-storage agent and method for preparing micro-storage straw

A technology of micro-storage and straw, which is applied in the field of forage preparation and processing and application of biological additives, can solve the problems of long ammoniation time, inability to effectively degrade straw fiber substances, inconvenient purchase of ammonia water, etc., and achieves good palatability and micro-storage. The effect of improving the intake of rice straw

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: the preparation of composite micro storage agent

[0027] (1) According to the addition ratio shown in the following micro-storage formulations 1-3, weigh the formulation raw materials, grind them into powder, mix them uniformly at room temperature to obtain composite micro-storage agents respectively.

[0028] Micro-storage formula 1 (by weight):

[0029] 0.31 parts of Bacillus subtilis, 0.31 parts of Enterococcus faecalis, 1.54 parts of cellulase, 4.62 parts of xylanase, 76.92 parts of brown sugar, 15.38 parts of table salt, and 0.92 parts of acidifier.

[0030] Micro-storage formula 2 (by weight):

[0031] 0.15 parts of Bacillus subtilis, 0.15 parts of Enterococcus faecalis, 1.54 parts of cellulase, 1.54 parts of xylanase, 80.31 parts of brown sugar, 15.38 parts of table salt, and 0.92 parts of acidifier.

[0032] Micro-storage formula 3 (by weight):

[0033] 0.46 parts of Bacillus subtilis, 0.15 parts of Enterococcus faecalis, 0.46 parts of cellulas...

Embodiment 2

[0039] Embodiment 2: the preparation of micro-storage rice straw

[0040]Produce micro-storage rice straw with micro-storage formula 1 below, and concrete operation process is as follows:

[0041] (1) Weigh out each raw material according to the consumption of various raw materials in the micro-storage agent formula and mix them uniformly;

[0042] The composite microstorage agent includes the following components by weight: 0.31 parts of Bacillus subtilis, 0.31 parts of Enterococcus faecalis, 1.54 parts of cellulase, 4.62 parts of xylanase, 76.92 parts of brown sugar, 15.38 parts of table salt, acidified 0.92 parts of the agent.

[0043] (2) Weigh the micro-storage agent according to the amount of adding 6.5 kilograms of compound micro-storage agent per 100 kilograms of dry rice straw, put it into a large plastic bucket, and first use 20 kilograms of water temperature to dissolve the micro-storage agent with warm water of 30 to 40°C, then Then add 100 kg of water and stir w...

Embodiment 3

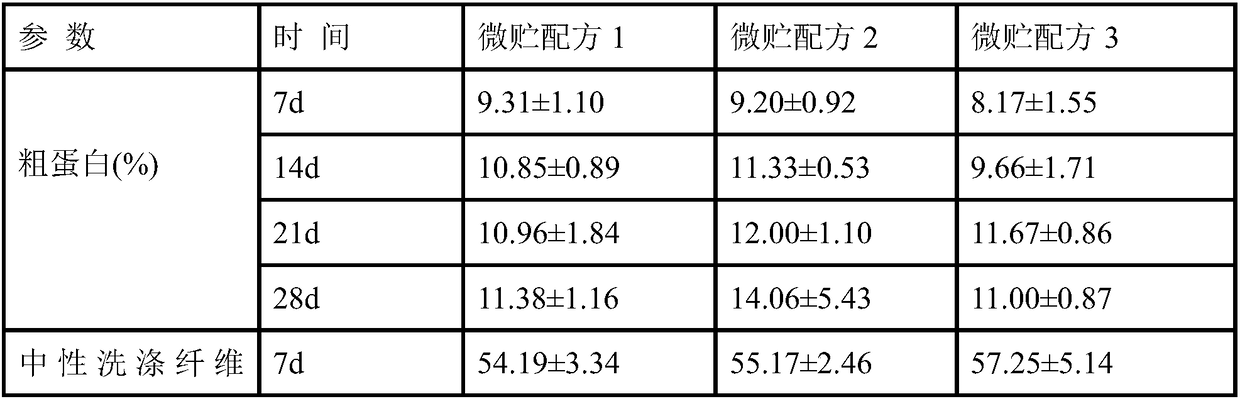

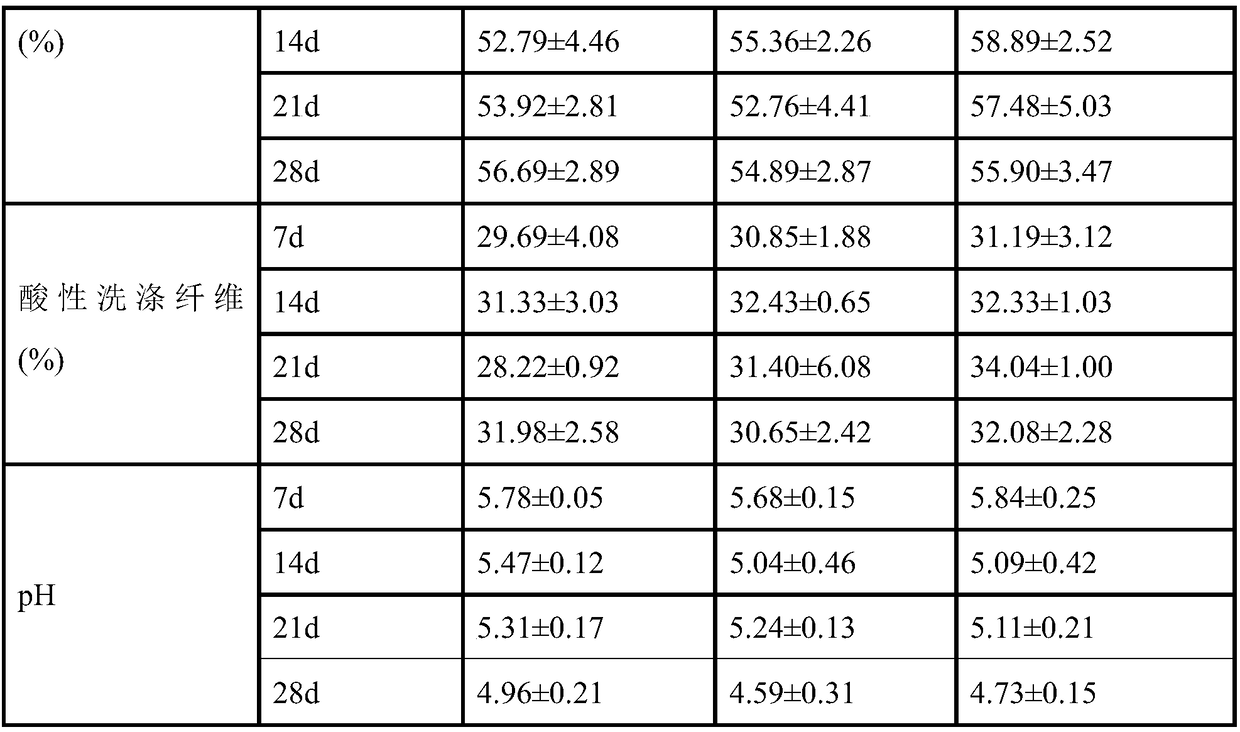

[0047] Detect the content of crude protein, neutral detergent fiber and acid detergent fiber in the micro-storage rice straw prepared by the method of Example 2, and detect the non-storage rice straw as a comparison at the same time, adopt the Kjeldahl method to measure the CP content and adopt the VanSoest method Determination of neutral and acid detergent fiber content, test results are shown in Table 2:

[0048] Table 2

[0049] category

crude protein

acid detergent fiber

micro-storage straw

5.47%

48.58%

21.58%

untreated straw

4.51%

66.91%

33.48%

[0050] It can be seen from the above table that compared with untreated dry straw, the crude protein of micro-storage rice straw increased by 21.29%, while neutral detergent fiber and acid detergent fiber decreased by 27.40% and 35.56% respectively.

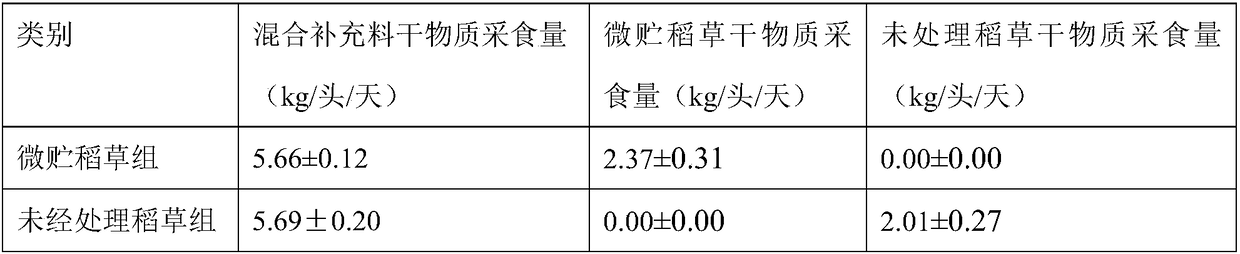

[0051] The micro-storage rice straw prepared in Example 2 is used for the raising of beef cattle t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com