Nutritious multi-grain granular dietary supplement for infants and preparation method thereof

A technology for nutritional granules, infants and young children, applied in the fields of food science, food ingredients, food forming, etc., can solve the problems of nutrient loss, low digestibility, insufficient chewing, etc., and achieve high digestibility, good digestibility, and convenient eating. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0079] A preparation method for instant multi-grain nutritional granule supplementary food for infants, comprising the following steps:

[0080] (1) According to the ratio of 80% of triticale flour, 8.37% of black rice flour, 11.36% of black bean flour and 0.27% of black sesame flour, the raw materials were mixed and added with water, and then stirred for 10-25min to make the mixture evenly, and the mixed material was obtained. The water content of the mixed material is 24-28wt%.

[0081] (2) Extrusion and puffing: Extrude and puff the mixed material in step (1) at an extrusion temperature of 160-170° C. and a screw speed of 7-13 Hz to obtain an expanded mixed material.

[0082] (3) Drying: the puffed mixture in step (2) is made into a granular material of 0.45-0.9mm through a granular food supplement forming device, and then the granular material is dried at 50-70°C for 6- After 10 hours, the granule food supplement was obtained.

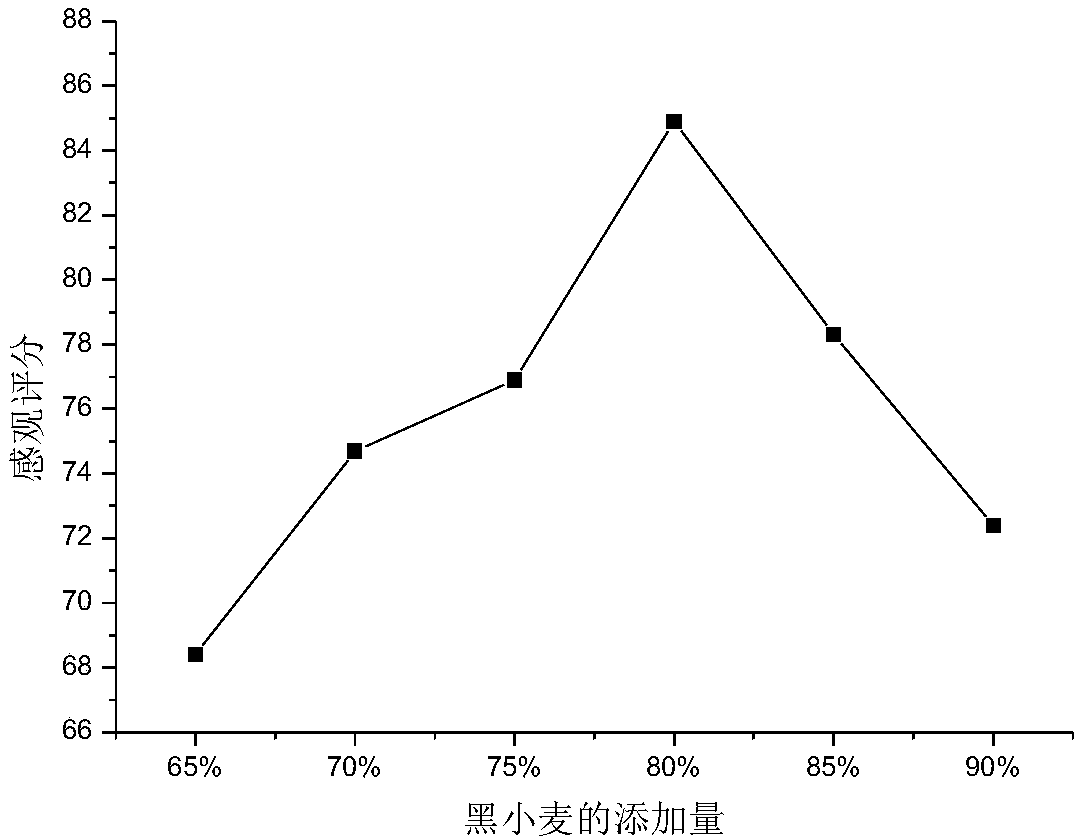

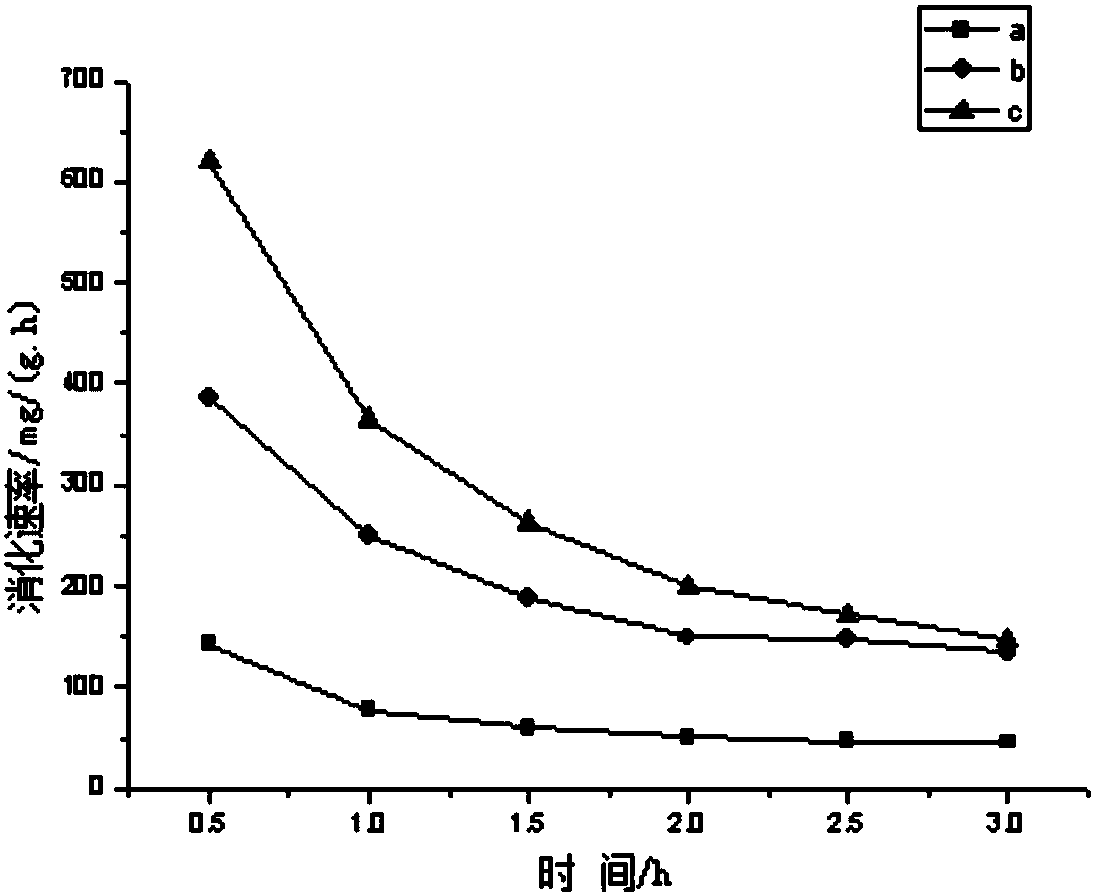

[0083] According to the three-factor three...

Embodiment 16

[0105] According to the ratio of 80% of triticale flour, 8.37% of black rice flour, 11.36% of black bean flour and 0.27% of black sesame flour, the mixture was mixed with water until the water content was 24wt%, and stirred for 15 minutes. Put the uniformly stirred mixture into the extrusion extruder, extrusion conditions: extrusion temperature 165 ° C, screw speed 10Hz, to obtain the puffed mixture, the puffed mixture is made into granular material through a molding device, and then the obtained The granular material was dried at 65° C. for 8 hours to obtain a granular food supplement with a particle size of 0.45-0.9 mm. According to the above measurement method, the gelatinization degree of the granular food supplement is 94.63%, the rehydration rate is 5.05%, the digestibility is 92.89%, and the comprehensive score is 192.57.

[0106] Adopt the following method to test the nutrient composition of embodiment 16 gained granule complementary food:

[0107] Refer to GB 5009.5-...

Embodiment 17

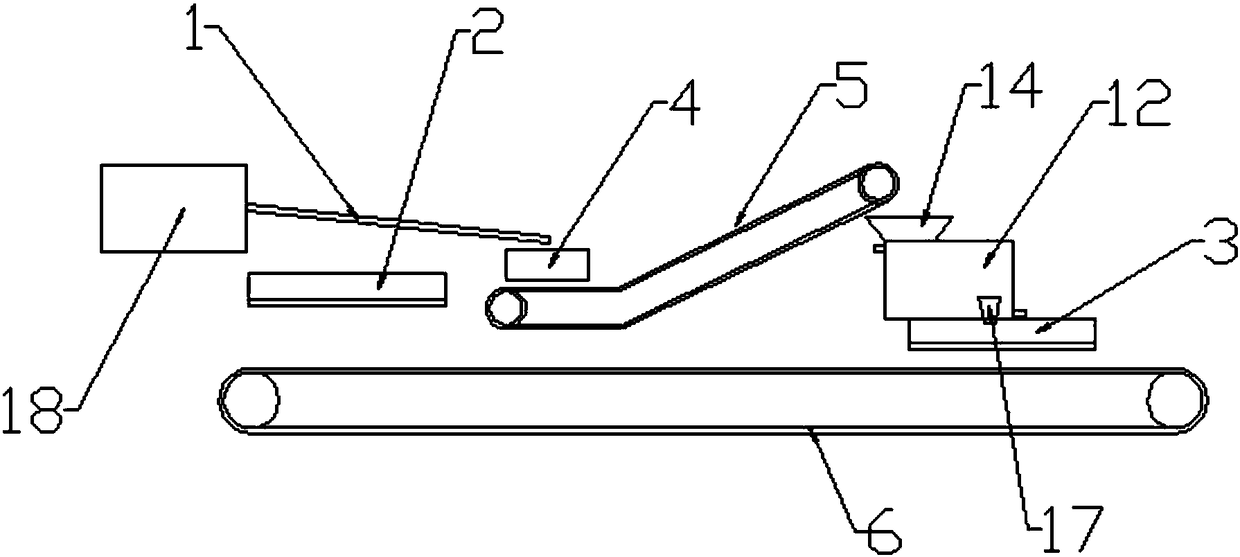

[0134] Such as Figure 3-9 , the particle supplementary food molding device includes a cutter mechanism, a vibrating screen mechanism, a transport mechanism and a crushing mechanism, the cutter mechanism is arranged at the discharge port of the extruder 18, and the vibrating screen mechanism includes a The first vibrating screen 1 coordinated by the mechanism, the second vibrating screen 2 arranged below the first vibrating screen 1 and the third vibrating screen 3 arranged on the crushing mechanism, the aperture of the first vibrating screen 1 is 1 mm, the aperture size of the second vibrating screen 2 is 0.4 mm, the aperture size of the third vibrating screen 3 is 0.4 mm, and the first vibrating screen 1, the second vibrating screen 2 and the third vibrating screen 3 are arranged obliquely. The conveying mechanism includes a first conveying belt 4 arranged below the tail end of the first vibrating screen 1, a second conveying belt 5 arranged below the first conveying belt 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com