Dust detecting and screening device

A screening and dust technology, applied in the direction of measuring device, filter screen, grille, etc., can solve the problems of inconvenient operation and high cost, and achieve the effect of convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Further detailed explanation through specific implementation mode below:

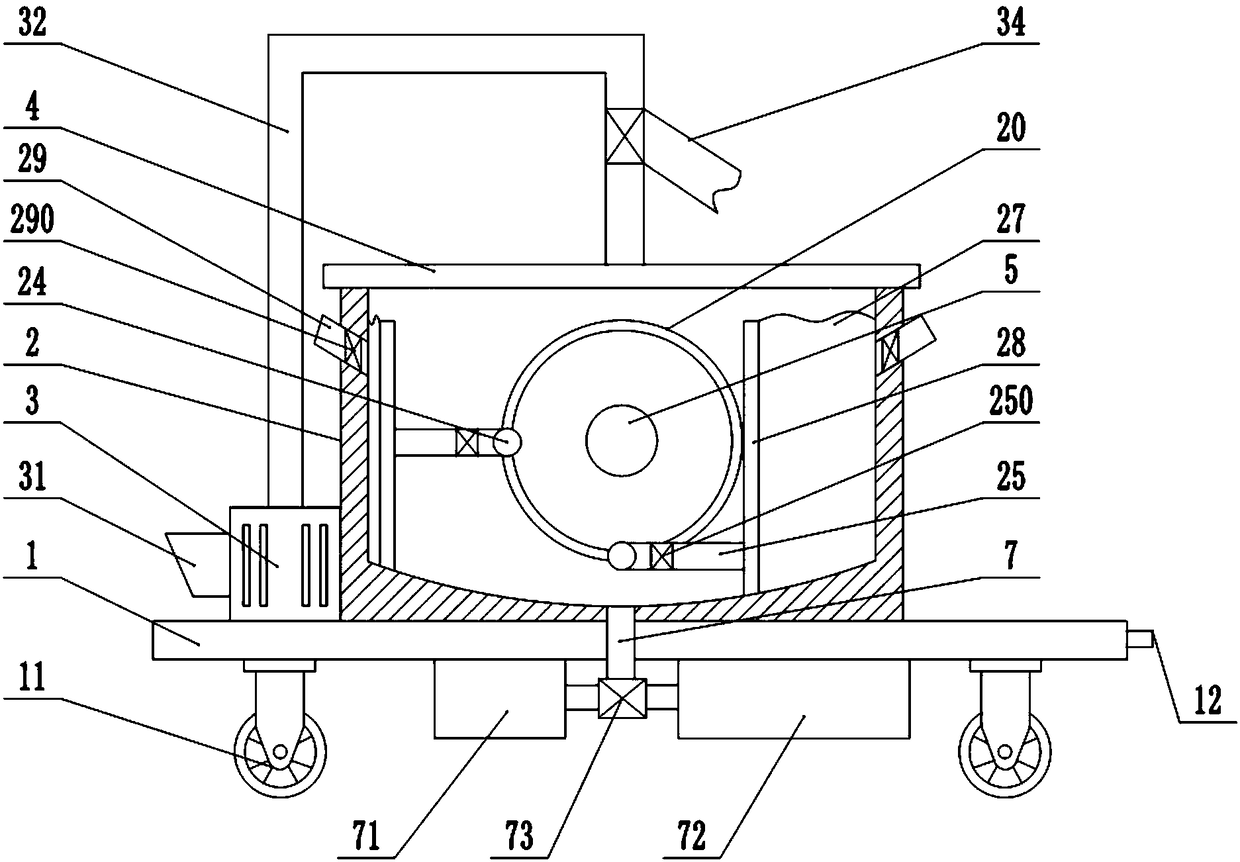

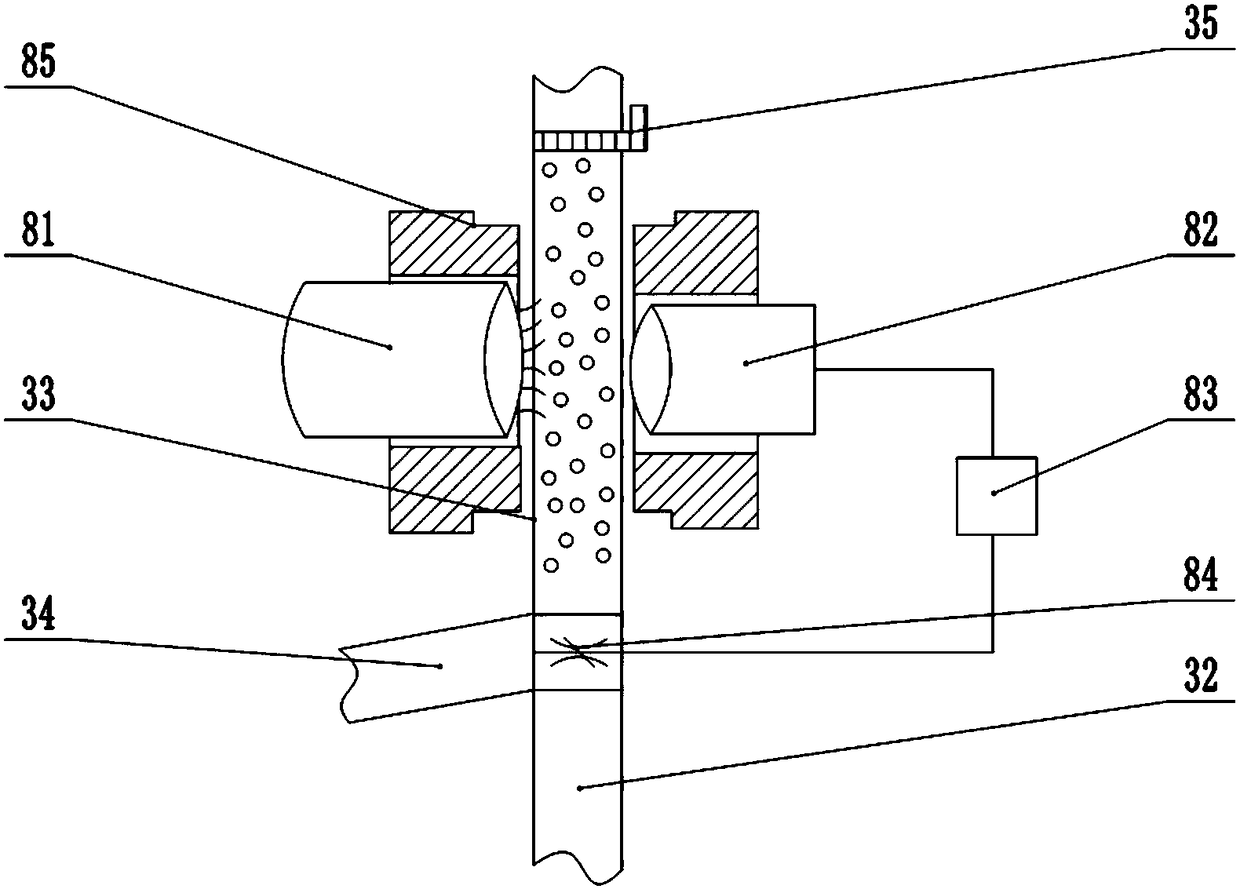

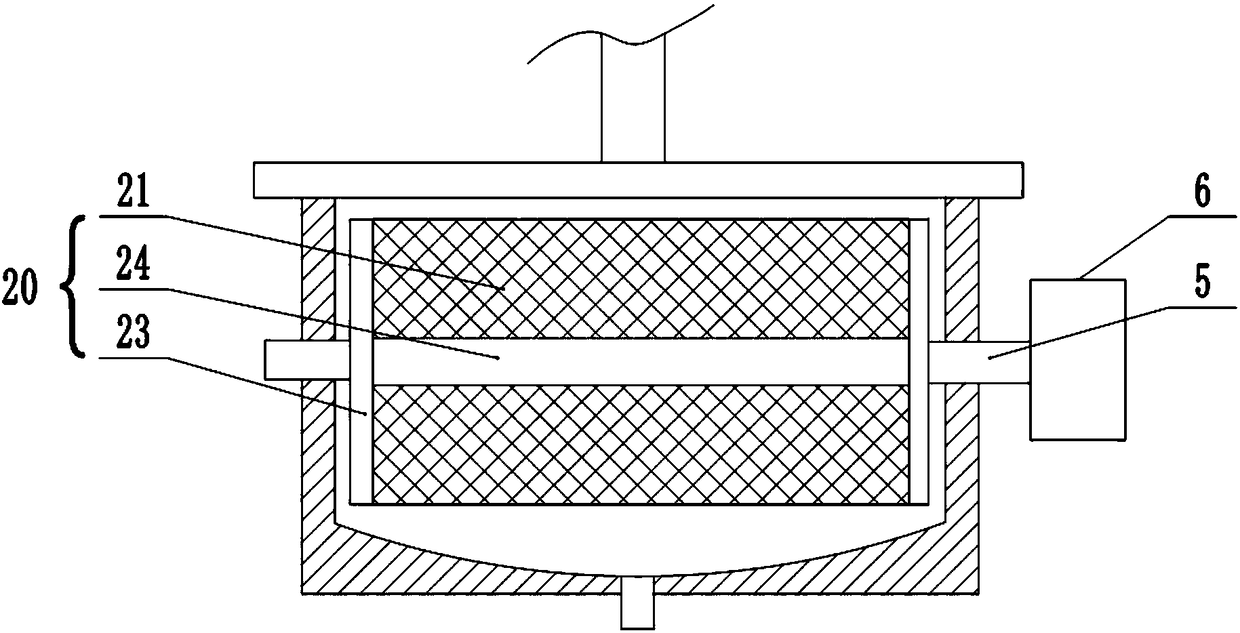

[0026] The reference signs in the drawings of the description include: base 1, universal wheel 11, pull ring 12, dust removal box 2, sieve filter cylinder 20, sieve filter plate 21, feed hole 22, fixed plate 23, support rod 24 , conduit 25, air outlet one-way valve 250, air bag 27, baffle plate 28, air intake pipe 29, air intake one-way valve 290, hoist 3, feeding port 31, feeding pipe 32, transparent pipe 33, bifurcated pipe 34, Filter screen 35, sealing cover 4, rotating shaft 5, motor 6, discharge pipe 7, dust collection box 71, material box 72, reversing valve 73, light emitting device 81, photoelectric conversion device 82, ammeter 83, regulating valve 84, shading Cover 85.

[0027] The embodiment is basically as attached figure 1 Shown:

[0028] The dust detection and filtering device includes a base 1 and a dust removal box 2 installed on the base 1. The top of the dust removal box 2 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com