Multi-dimensional motion processing robot and cluster

A robot and motion technology, used in metal processing equipment, manipulators, manufacturing tools, etc., can solve the problems of high-power, high-loss, large-displacement motion range design, stress recovery deformation, low processing efficiency, etc., to reduce processing costs and processing difficulties. , avoid machine use, improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

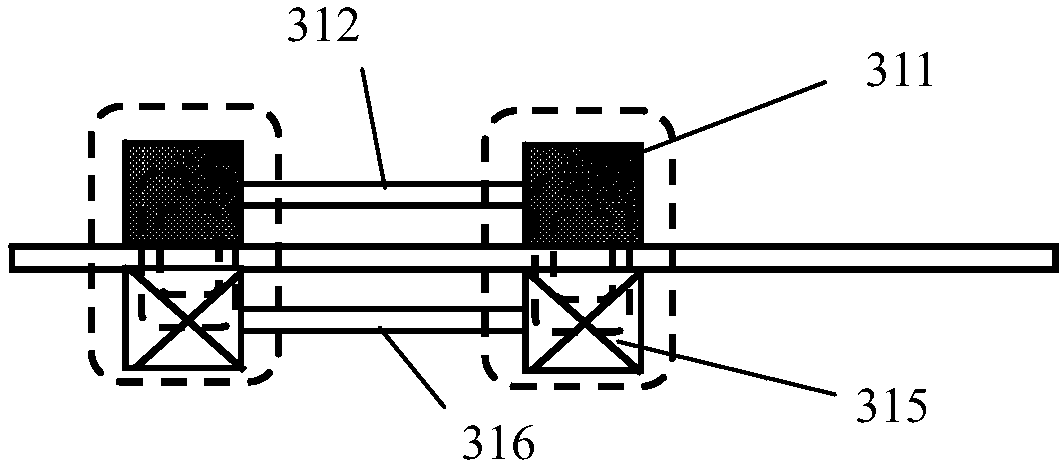

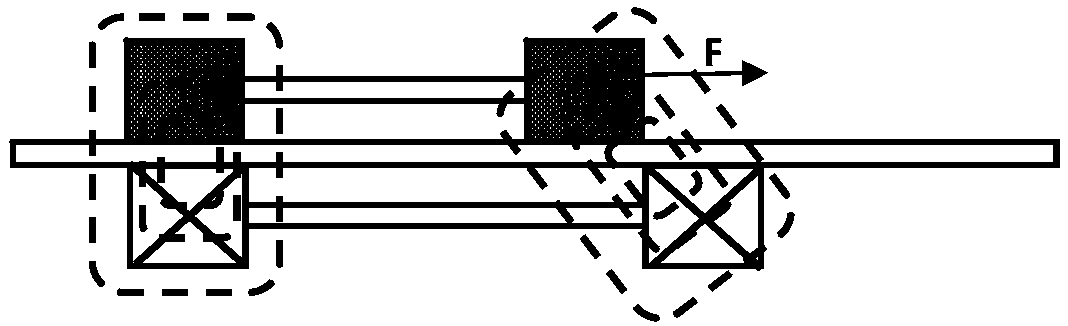

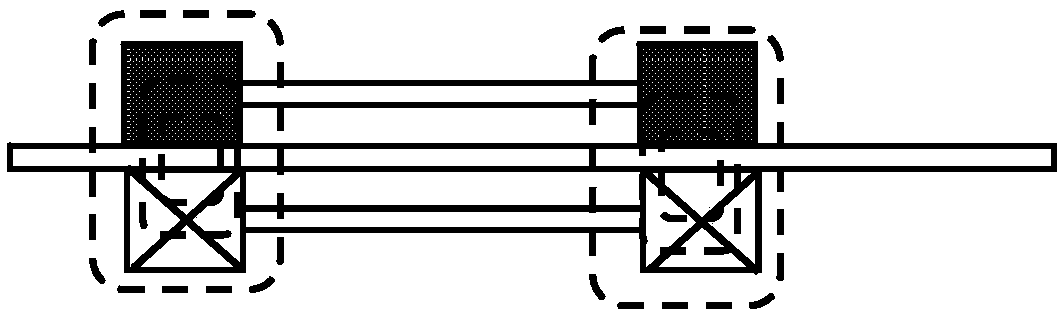

[0065] Such as Figure 1 to Figure 5 As shown, in this embodiment, the absorber 310 also constitutes the traction member 320, and the absorber 310 on the first body 110 is arranged opposite to the absorber 310 on the second body 120, forming two pairs of absorber 310 , these two pairs of absorbing parts 310 constitute any two legs for driving in the robot with more than three legs. Preferably, when the center is lower and the surface area of the absorbing member 310 is large enough to support and balance the overall structure, the two pairs of absorbing members 310 can also form a biped robot. The specific structure is described as follows:

[0066] The adsorption piece 310 included in the first body 110 forms a first adsorption block 311, and a plurality of first adsorption blocks 311 are connected by a first driving rod 312; the adsorption piece 310 included in the second body 120 forms a second adsorption block. Block 315 , a plurality of second adsorption blocks 315 ar...

Embodiment 2

[0071] This embodiment is a modification of the structure provided in Embodiment 1, such as Figure 6 , Figure 7 As shown, the absorber 310 also constitutes the traction member 320 at the same time, and three pairs of absorber 310 are arranged in total, thereby forming a three-legged robot. The absorber 310 is connected to the support member 400 through a connecting rod 450 , the connecting rod 450 acts like a leg, and the absorber 310 acts like a foot. The specific structure is described as follows:

[0072] The adsorption part 310, the connecting rod part 450 and the support part 400 contained in the first body 110 respectively form the first adsorption block 311, the first connecting rod 451 and the first support platform 401, and the second body 120 contains The adsorption part 310 , the connecting rod part 450 and the supporting part 400 respectively form the second adsorption block 315 , the second connecting rod 452 and the second supporting platform 402 . Processin...

Embodiment 3

[0075] This embodiment is a modification of the structure of Embodiment 2. In this embodiment, among the three pairs of adsorbents 310, only one pair of adsorbents 310 also functions as traction members 320, and the other two pairs of adsorbents 310 only function as support points. To drive the motion of the whole multi-dimensional action processing robot.

[0076] Preferably, the functional components 300 on the first body 110 and the functional components 300 on the second body 120 are completely symmetrical, partially symmetrical or completely asymmetrical in structure. For example, for the adsorption piece 310 on the first body 110 and the adsorption piece 310 on the second body 120 , under the condition of complete adsorption, the positions of the two in the projection along the thickness direction of the workpiece 200 can be completely Overlap or, also can be mutually staggered. Preferably, the adsorption member 310 may not be in direct contact with the workpiece 200 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com