Air purifying coating capable of releasing anions and preparation method thereof

An air purification, negative ion technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problem of short release time of negative ions, and achieve the effect of low volatile organic compound content, lower production cost and environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

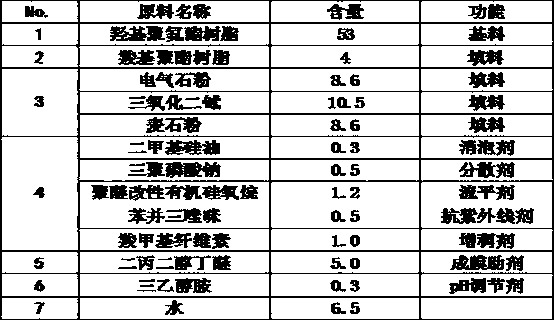

[0042] This implementation is a kind of air-purifying coating that releases negative ions, and the raw material component that comprises following mass percentage composition is shown in Table 1:

[0043] The air-cleaning coating raw material that releases negative ion of table 1 embodiment 1

[0044]

[0045] The specific preparation steps of the air-purifying coating for releasing negative ions of the present embodiment are as follows:

[0046] (1) First, add hydroxyl polyurethane resin and functional additives into the reactor and stir at room temperature for 20 minutes to fully emulsify;

[0047] (2) Add carboxyl polyester resin and negative ion powder into the reactor in sequence, stir at 2000rpm, and disperse at high speed to obtain a uniformly dispersed emulsion;

[0048] (3) Finally, add film-forming aids, pH regulators and water into the reaction to adjust the pH and viscosity of the system. After the system is stable, the desired air-purifying coating that releas...

Embodiment 2

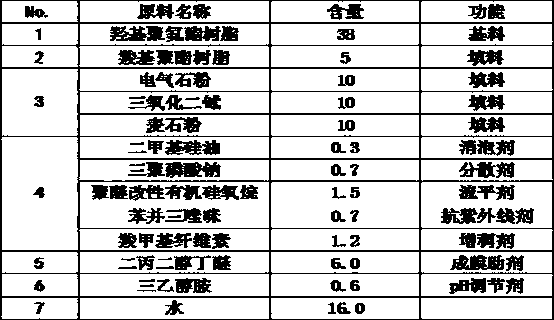

[0050] This implementation is a kind of air-purifying coating that releases negative ions, and the raw material component that comprises following mass percentage composition is shown in Table 2:

[0051] The air-cleaning coating raw material that releases negative ion of table 2 embodiment 2

[0052]

[0053] The specific preparation method of the air-purifying coating that releases negative ions of the present embodiment is the same as that of Example 1.

Embodiment 3

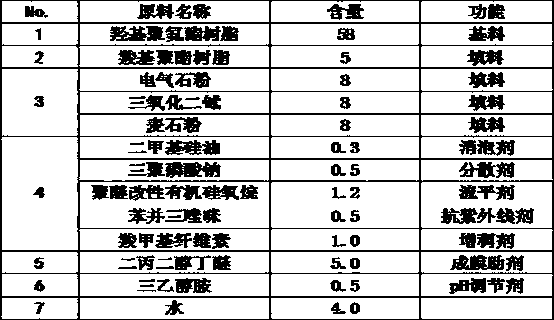

[0055] This implementation is a kind of air-purifying coating that releases negative ions, and the raw material component that comprises following mass percentage composition is shown in Table 3:

[0056] The air-cleaning coating raw material that releases negative ion of table 3 embodiment 3

[0057]

[0058] The specific preparation method of the air-purifying coating that releases negative ions of the present embodiment is the same as that of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com