Water washing method for improving filling power of down feather

A technology of bulkiness and down, applied in the field of improving the bulkiness of down, can solve the problem of large amount of water for rinsing, and achieve the effects of avoiding excessive loss, reducing dosage, and reducing the amount of foam generated.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

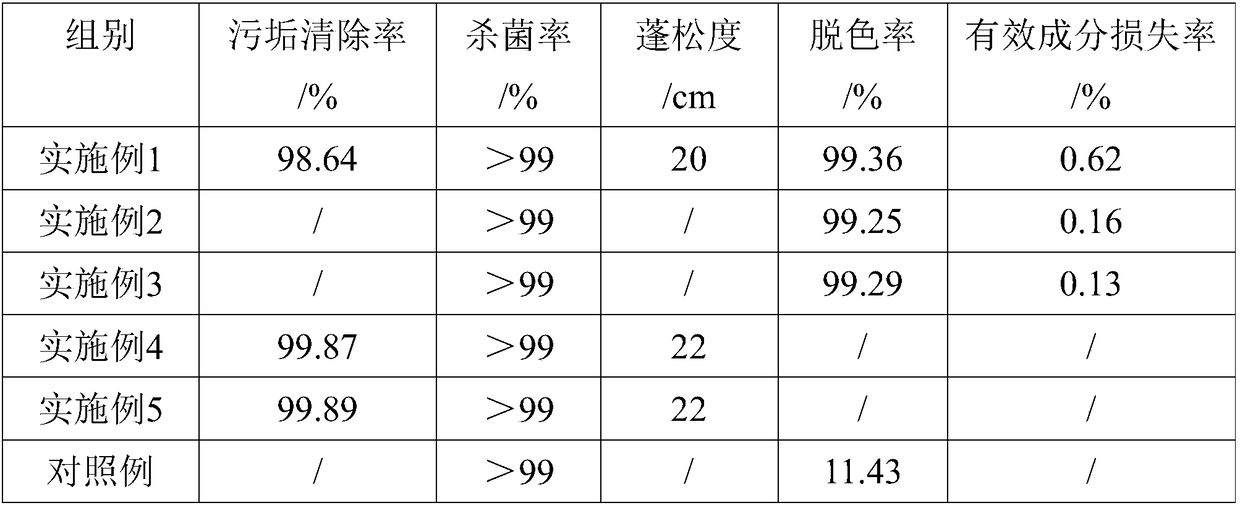

Examples

Embodiment 1

[0029] Feed the feathers into the drum type washing machine first, and inject cleaning liquid into the drum type washing machine. The cleaning liquid is prepared by adding water to the cleaning agent. The temperature of the cleaning liquid is maintained at 45-50 ° C. After washing for 15 minutes, drain the cleaning liquid. Then pour clean water into the drum washing machine, rinse for 10 minutes and drain the rinse solution, then send the down to the drum dryer and dry it at 70-75°C. After drying, turn off the temperature switch and open the outlet After blowing for 15 minutes, go down.

[0030] The cleaning agent is composed of the following raw materials in weight percentage: 35% of ethoxylated fatty acid methyl ester, 26% of sodium cocoyl methyl taurate, 25% of food grade polyglutamic acid, 8% of ethoxylated lanolin, Bactericidal traditional Chinese medicine extract 2%, sodium cocoyl glycinate 2%, compound biological enzyme 2%.

[0031] Wherein, the composite biological en...

Embodiment 2

[0034] Feed the feathers into the drum type washing machine first, and inject cleaning liquid into the drum type washing machine. The cleaning liquid is prepared by adding water to the cleaning agent. The temperature of the cleaning liquid is maintained at 45-50 ° C. After washing for 15 minutes, drain the cleaning liquid. Then pour clean water into the drum washing machine, rinse for 10 minutes and drain the rinse solution, then send the down to the drum dryer and dry it at 70-75°C. After drying, turn off the temperature switch and open the outlet After blowing for 15 minutes, go down.

[0035] The cleaning agent is composed of the following raw materials in weight percentage: 35% of ethoxylated fatty acid methyl ester, 26% of sodium cocoyl methyl taurate, 25% of food grade polyglutamic acid, 8% of ethoxylated lanolin, Bactericidal traditional Chinese medicine extract 2%, sodium cocoyl glycinate 2%, compound biological enzyme 2%.

[0036] Wherein, the composite biological en...

Embodiment 3

[0040] Feed the feathers into the drum type washing machine first, and inject cleaning liquid into the drum type washing machine. The cleaning liquid is prepared by adding water to the cleaning agent. The temperature of the cleaning liquid is maintained at 45-50 ° C. After washing for 15 minutes, drain the cleaning liquid. Then pour clean water into the drum washing machine, rinse for 10 minutes and drain the rinse solution, then send the down to the drum dryer and dry it at 70-75°C. After drying, turn off the temperature switch and open the outlet After blowing for 15 minutes, go down.

[0041] The cleaning agent is composed of the following raw materials in weight percentage: 35% of ethoxylated fatty acid methyl ester, 26% of sodium cocoyl methyl taurate, 25% of food grade polyglutamic acid, 8% of ethoxylated lanolin, Bactericidal traditional Chinese medicine extract 2%, sodium cocoyl glycinate 2%, compound biological enzyme 2%.

[0042] Wherein, the composite biological en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com