Novel environment-friendly and energy-saving wall heat-preservation wallboard prepared from domestic waste and construction technique thereof

A technology for domestic waste and thermal insulation boards, which is used in thermal insulation, manufacturing tools, ceramic molding machines, etc., can solve problems such as thermal bridges, weak paste, and reduced wall thermal insulation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The preparation of a novel green energy-saving wall insulation board prepared from domestic waste comprises the following steps:

[0030] A. Prepare a square insulation board mold with a size of 600mm×600mm and a thickness of 120mm;

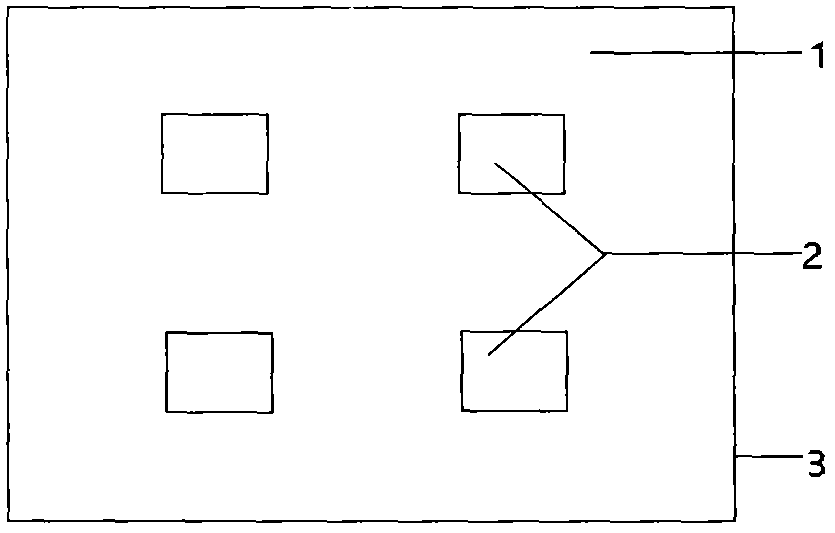

[0031] B. The mold is at the position of the square two-way dovetail groove (2) of the insulation board, reserve four squares of 150mm×150mm, the depth is 25mm, and the center distance between the squares is 300mm;

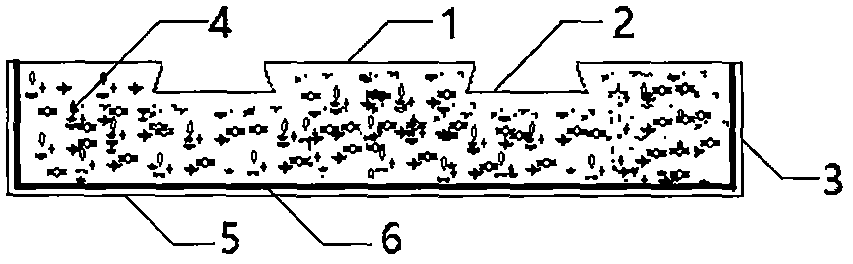

[0032] C. Preparation of waste concrete, the concrete material is composed of cement, fly ash, recycled concrete aggregate, rice husk, waste rubber particles, and waste fabric fibers;

[0033] D. Concrete is poured, vibrated on a vibrating table, and the plate matrix (4) containing waste aggregates and four 150mm×150mm squares of 150mm×150mm in the position of the square two-way dovetail groove (2) are made, with a depth of 25mm;

[0034] E. Conserve the concrete of the insulation board for 28 days to make it reach the design...

Embodiment 2

[0039] A construction process of a new type of green energy-saving wall insulation board prepared from domestic waste, comprising the following steps:

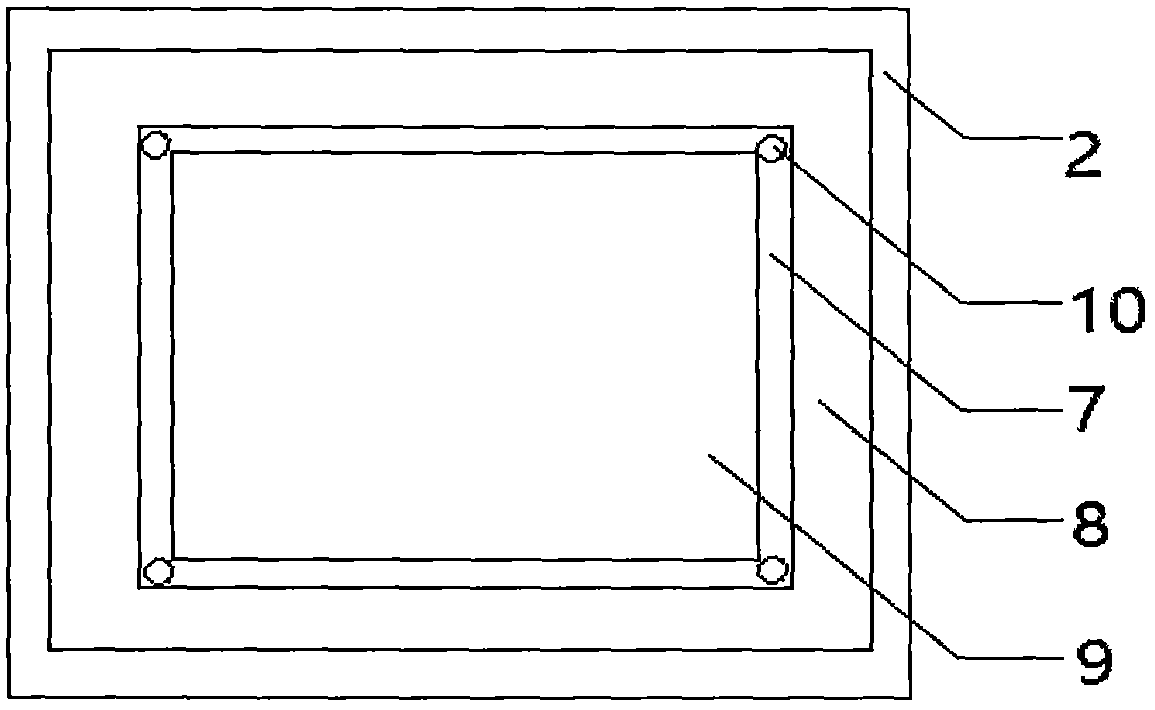

[0040] A. Stretch the line on the base wall (11), and design and arrange the exact position of the insulation board;

[0041] B. Determine the positions of the wall fixing frame (7) and the fixing expansion bolt (10) according to the position of the insulation board;

[0042] C. Drill holes according to the position of the fixed expansion bolt (10) marked;

[0043] D. four wall fixing frames (7) that fix the first insulation board are installed;

[0044] E. Apply bonding mortar (8) on the outside of the four wall fixing frames, and the thickness and height of the mortar are 35mm;

[0045] F. Press the four square two-way dovetail grooves (2) of the board base (4) containing waste aggregates into the bonding mortar (8) of the four wall fixing frames (7), and gently use a wooden hammer Tap to control position and depth;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com