An enlarged head prestressed pipe pile and its construction method

A technology of prestressed pipe piles and construction methods, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of pile damage, accelerated corrosion of steel bars in piles, hidden dangers of bearing performance of uplift piles, etc. The effect of bearing capacity and pullout resistance, avoiding pile shaft cracks, improving the bearing capacity of pile foundation and material utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

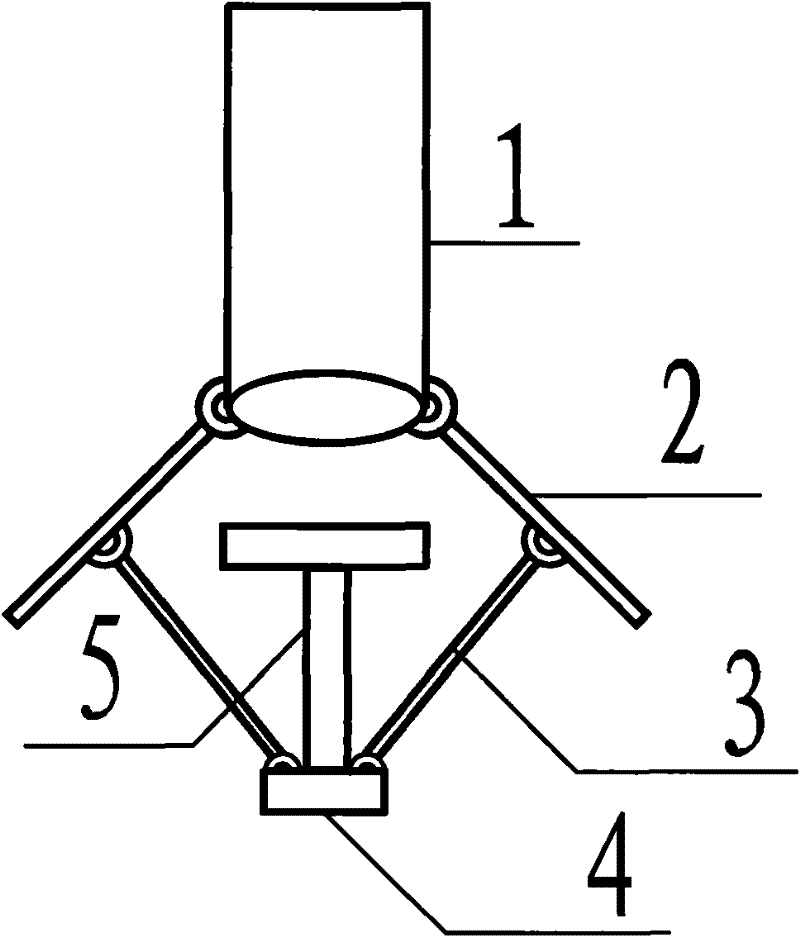

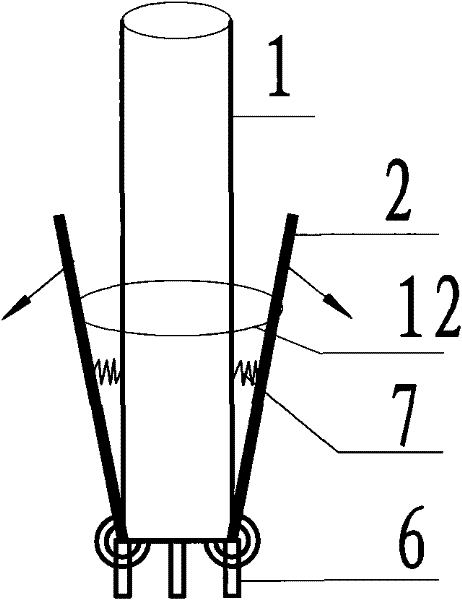

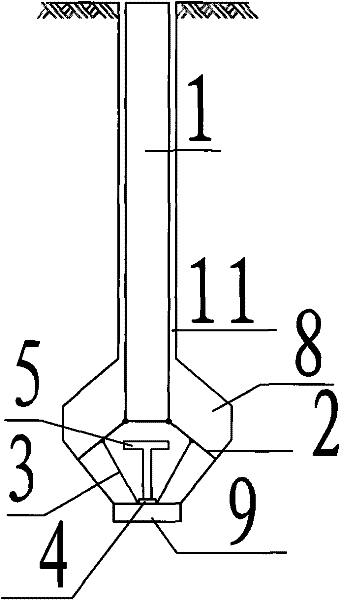

[0025] Preferred embodiments of the present invention will be described below with reference to the accompanying drawings. figure 1 It is a structural schematic diagram of the first embodiment of an enlarged head prestressed pipe pile provided by the present invention. Such as figure 1 As shown, a prestressed pipe pile with an enlarged head provided by the present invention includes a pipe pile body 1, an end expansion reinforcement 2, a bottom connection reinforcement 3, a bottom connection block 4 and a limit "T" block 5, wherein the end The external expansion steel bar 2 is flexibly connected to the end of the pipe pile body 1 through a hinge, and the end expansion steel bar 2 is connected around the end of the pipe pile body 1 for a week, and the end expansion steel bar 2 is flexibly connected to one end of the bottom connecting steel bar 3 through a hinge together, and the other end of the bottom connecting steel bar 3 is movably connected to the bottom connecting block ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com