An energy-saving and environment-friendly system applied to combustion equipment

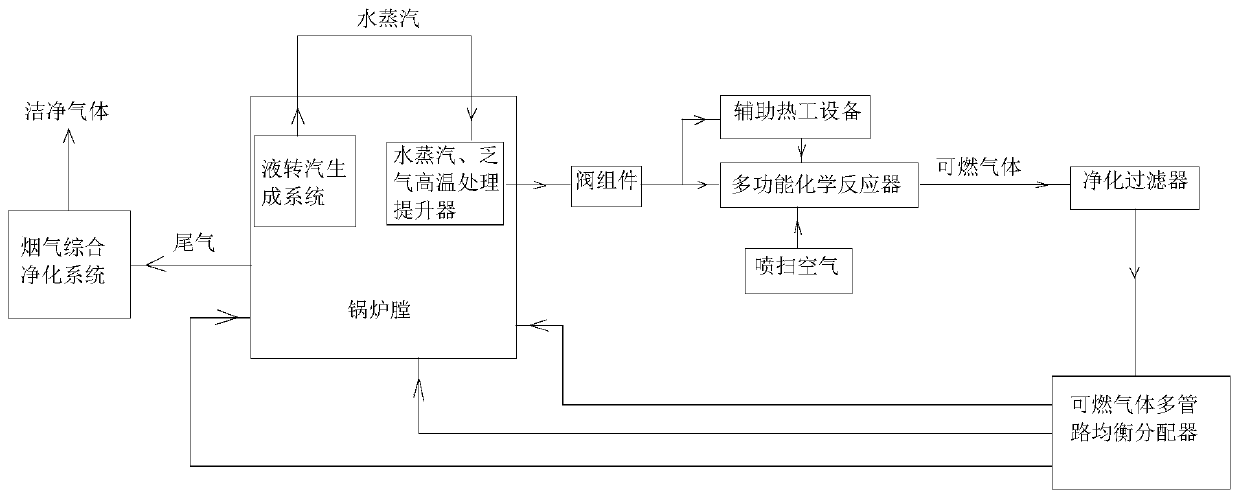

A combustion equipment, energy saving and environmental protection technology, applied in the steam generation method, burner, combustion type and other directions using pressure combustion, can solve the problems of sewage discharge, waste of fuel, failure to achieve energy saving and environmental protection, and achieve fuel saving and good desulfurization function. , the effect of perfect performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

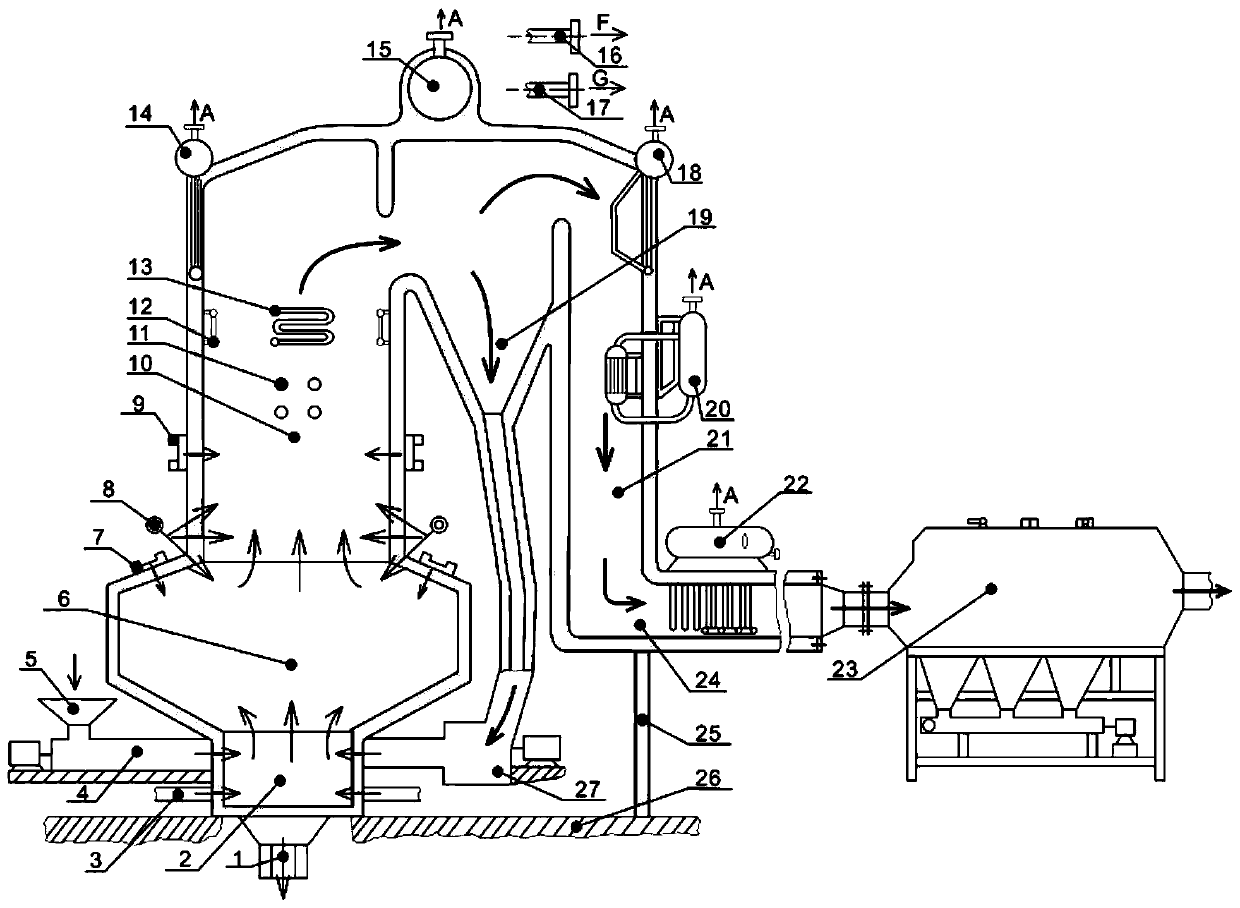

[0102] The heating area of 400 square meters new hot water boiler (for testing), energy-saving self-inspection data and combustion flame status introduction:

[0103] 1. Instruments for testing: thermoelectric thermometer (thermocouple), temperature digital display, time counter, manual monitoring record.

[0104] 2. Test furnace type: hot water boiler, 400 square meters of heating area. Energy consumption: square honeycomb-shaped high-energy medium fuel (15 pieces in total), air supply method: natural air intake and combustion.

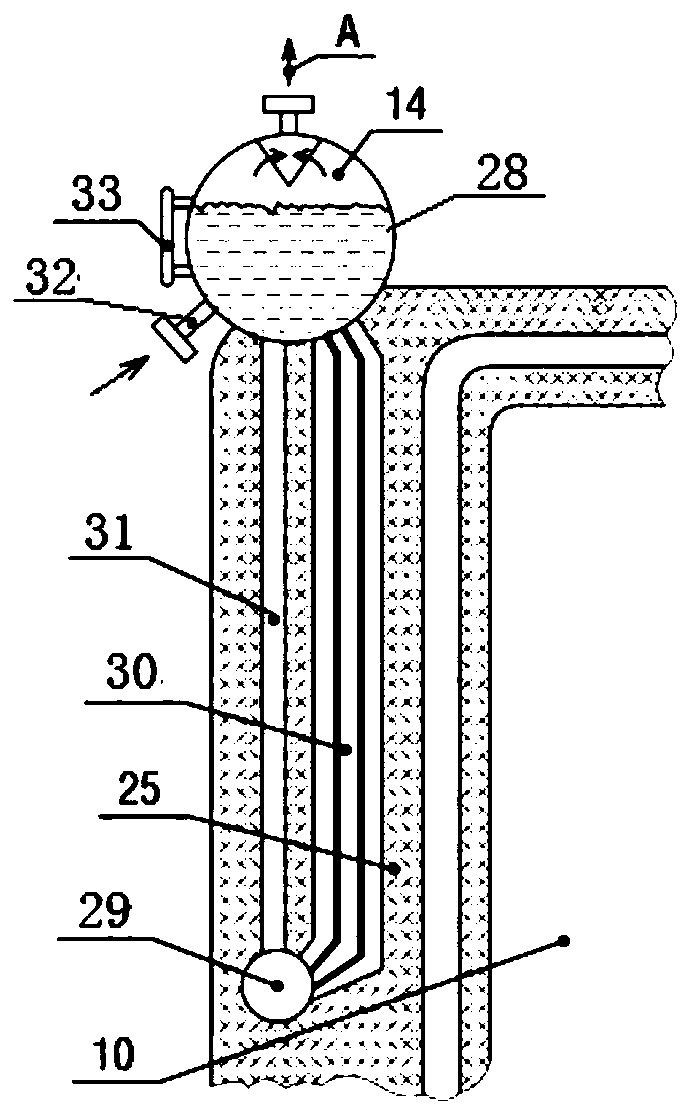

[0105] 3. The purpose of the test: the use and non-use of the combustible gas fuel produced by the designed and installed boiler gas-making system (ZRQJH system), what changes will be brought to the combustion in the boiler combustion chamber, and it can be confirmed that it is installed on the hot water boiler The unique ZRQJH system has a unique energy-saving function. The high-energy medium fuel and gaseous fuel are burned synchronously. The cl...

Embodiment 2

[0125]0.5 ton bulk coal steam boiler (for testing) detection unit detects desulfurization and energy saving items: energy saving 8%, sulfur emission concentration after desulfurization 116.88mg, m 3 . Flame changes in the combustion chamber: When no self-made gas is used, the combustion flame of coal burning is yellow-red and long flame. When the self-made gas of this furnace starts to be sprayed, the flame instantly changes to a white transparent flame. The temperature in the combustion chamber increases by an average of 100°C (detected by a thermometer in the detection unit). The nitrogen oxide reduction effect is not included in the detection item, but according to theoretical calculations, the present invention has a very good nitrogen oxide reduction function.

Embodiment 3

[0127] Introduction of self-inspection data and other performances of three-flame gas large-scale Chinese cooking stove (for testing)

[0128] Necessary conditions: 5 kg of water (weighed by electronic scale), gas flow meter, water temperature meter, and electronic clock. Detection data (%): 30% to 49% energy saving (energy saving data detected for a long time).

[0129] Cleanliness of the fire hole surface: After using the self-made gas for a long-term inspection test, the fire hole surface is still as new. When the fire hole surface that does not use self-made gas is first used for detection tests, black (blackened) appears.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com