Electrothermal quartz tube atomizer

A technology of atomizer and quartz tube, which is applied in the field of electrothermal quartz tube atomizer, can solve the problems of low temperature, difficult temperature control, easy electric shock, etc., and achieve the effect of convenient replacement operation, reliable performance and tight joint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

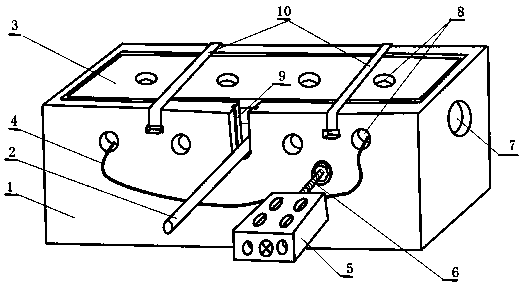

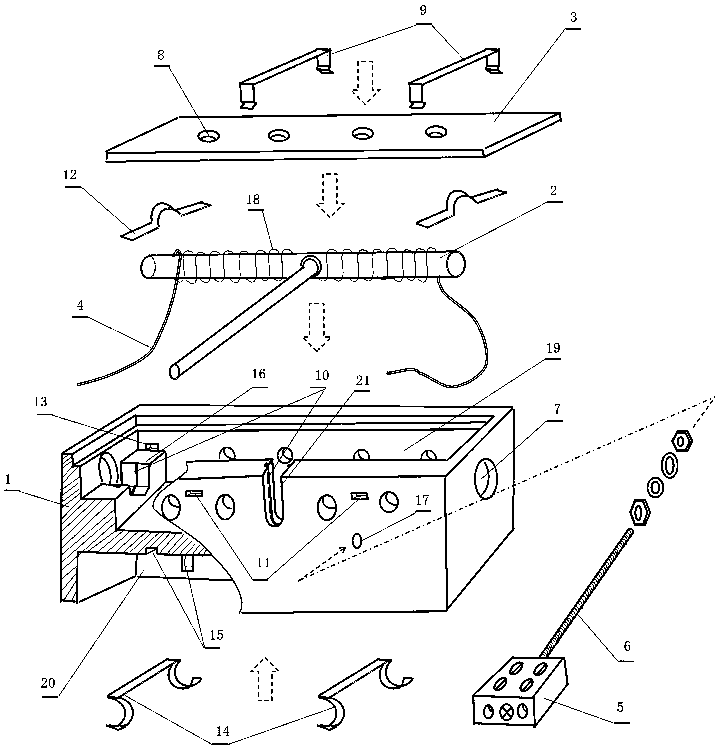

[0009] refer to figure 1 , figure 2 The shape and structure of the method are implemented according to the following steps.

[0010] 1. The main body of the seat body 1: it is made of pottery clay and fired. It is required to be able to withstand high temperature of 1200 ℃ and have good insulation performance. The lower groove 20 has two lower reed grooves 15, and two lower reeds 14 are inserted therein respectively to play the role of closely engaging with the flame atomizer. There are optical path holes 7 at both ends of the upper groove 19, and the aperture is about 10 mm; there are four ventilation holes 8 on both sides; there is a T-shaped quartz tube standpipe installation gap 21 in the middle of the front; there are T-shaped quartz tubes under the two ends of the upper groove 19 The support platform 16 has grooves and inserts asbestos rope bead 9 in the place where the T-shaped quartz tube standpipe installation gap 21 and the T-shaped quartz tube support platform 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com