High-safety lithium ion battery

A lithium-ion battery and electronic technology, applied in the direction of secondary batteries, battery electrodes, battery pack components, etc., can solve the problems of high thermal runaway risk, waste of space, etc., and achieve high utilization rate, high energy density, and space saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

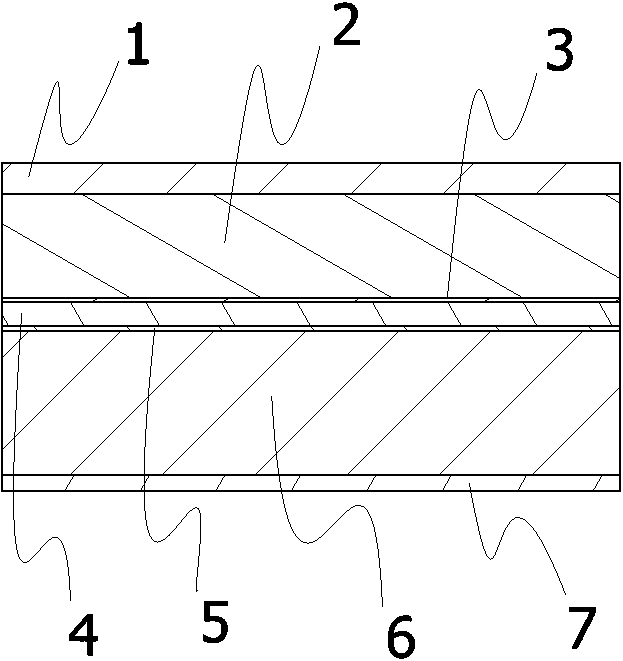

[0042] Figure 5 Shown is a schematic diagram of the structure of the multilayer coated electrode sheet of the positive electrode of the lithium ion battery. On the positive electrode current collector 1, the positive electrode inner layer electrode active material sublayer 2A and the positive electrode outer layer electrode active material sublayer 2B are coated sequentially. The key difference between sublayer 2A and sublayer 2B is the difference in the content of the conductive agent and the resulting difference in the electronic conductivity of the sublayers.

[0043] Positive electrode ingredient list A

sp

ks-6

PVDF

NMP

1000±0.5

18±0.1

12±0.1

21±0.1

450

[0045] Positive electrode ingredient list B

sp

ks-6

PVDF

NMP

1015±0.5

9±0.1

6±0.1

21±0.1

450

[0047] In the above two tables: sp conductive carbon black, ks-6 cond...

Embodiment 2

[0050] The difference between this embodiment and Embodiment 1 is that, in addition to the positive electrode, each side of the negative electrode current collector 7 is also coated with two layers. Similar to the positive electrode, the electronic conductivity of the two sublayers is also different. The electronic conductivity of the inner layer close to the negative electrode collector 7 is higher, while that of the outer layer is lower. Due to the high electronic conductivity of graphite itself, the electronic conductivity distribution of the negative electrode active material coating is adjusted by adjusting the binder content.

[0051] Negative electrode ingredient list A

[0052] artificial graphite

CMC powder

sp

SBR

NMP+deionized water

1000±0.5

15.8±0.1

10

54±0.1

50+1009

[0053] Negative electrode ingredient list B

[0054] artificial graphite

CMC powder

sp

SBR

NMP+deionized water

970±0.5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com