Bone cement type interbody fusion cage and operation method thereof

A bone cement and fusion device technology, applied in the field of intervertebral fusion devices, can solve the problems of non-growth, operation failure, easy invagination and loosening, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

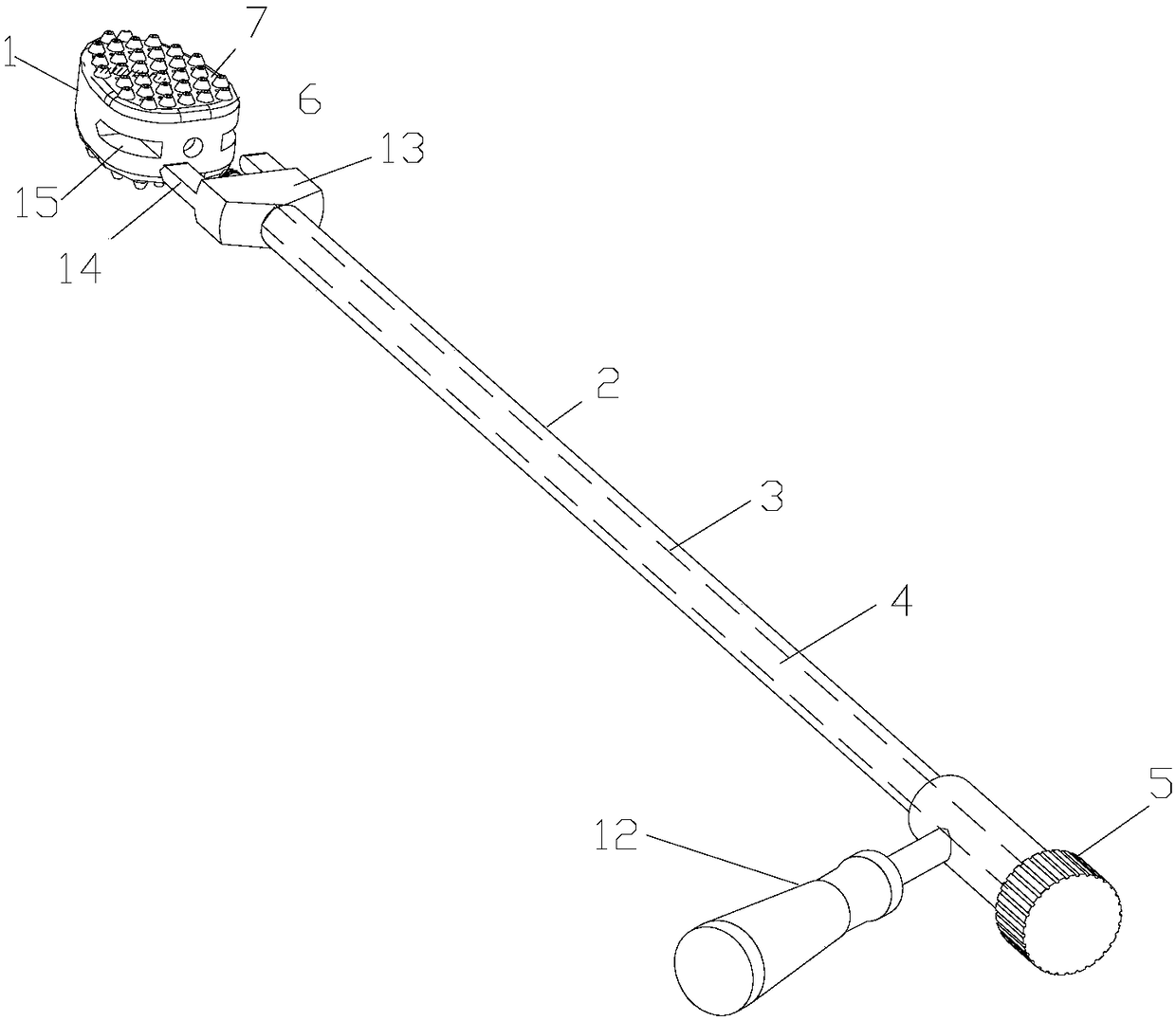

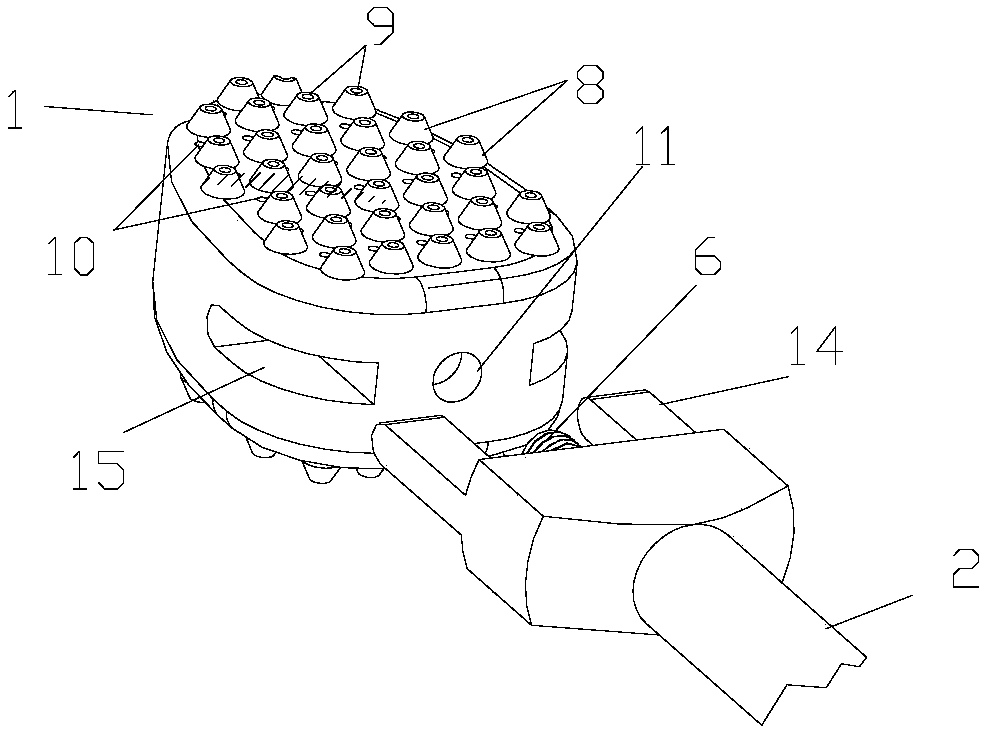

[0028] refer to figure 1 , 2 , this embodiment includes a bone cement fusion device 1, an injection rod 2, and a mounting screw 3. The injection rod is provided with an injection through hole 4, one end of which is open, and the other end is provided with a positioning protrusion. The injection through hole is coaxial and connected to the inner hole; one end of the installation screw 3 is provided with an end cap 5, and the other end is a threaded head 6, and the installation screw 3 passes through the injection through hole 4 of the injection rod 2, and its threaded head is the same as the bone cement type. The cage 1 is threadedly connected; the bone cement cage 1 is provided with a cavity, and has upper and lower two working surfaces 7, and the working surface 7 is provided with a plurality of raised spikes 8, and the spikes 8 are provided with long The through hole 9 and the working surface are provided with a short through hole 10, the long through hole 9 and the short t...

Embodiment 2

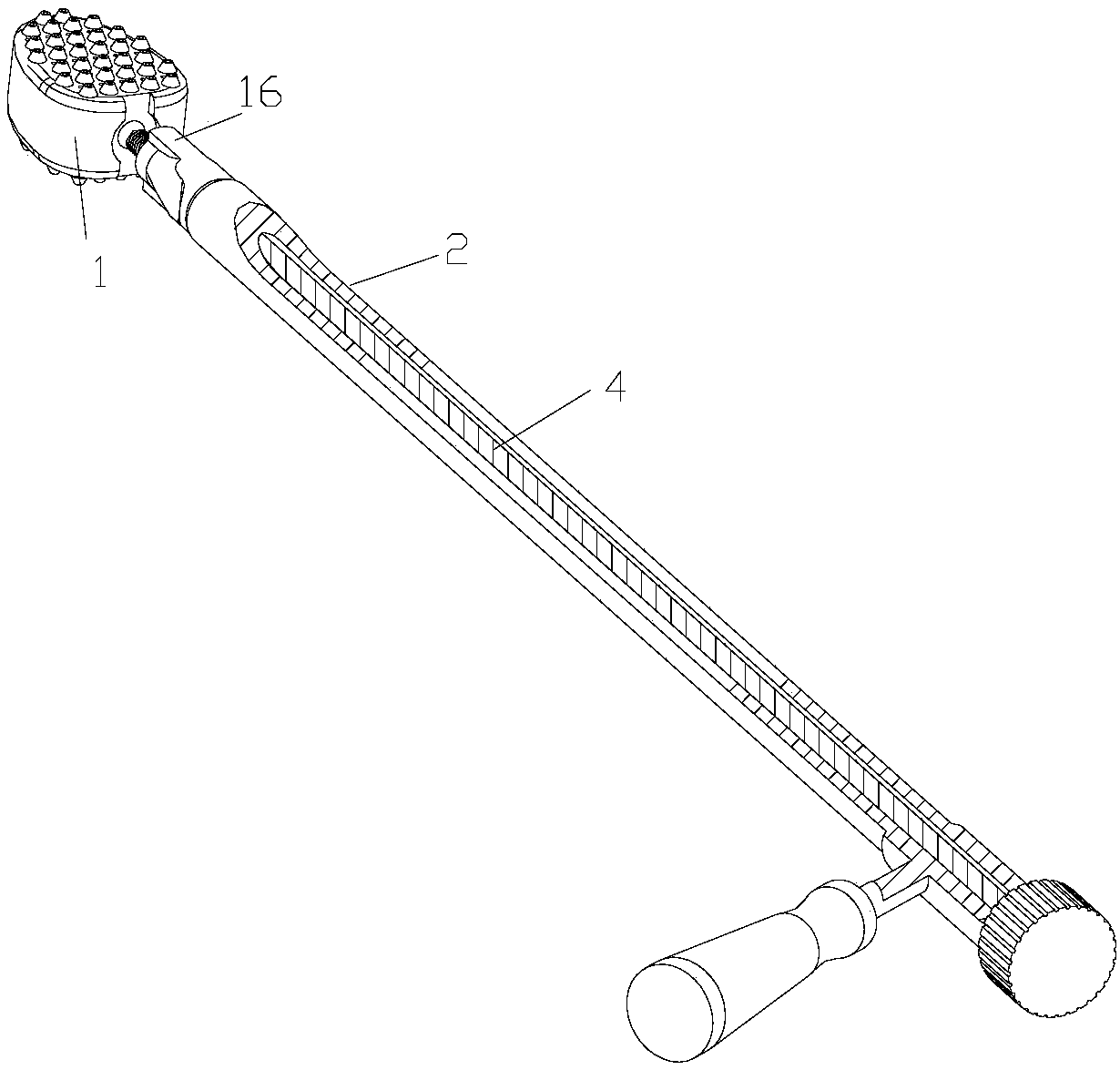

[0036] refer to image 3 , 4 , this embodiment is basically the same as Embodiment 1, the difference lies in that the structures of the positioning protrusions and the positioning concave holes are different. Two convex prisms 16 are arranged at the front of the positioning bump, and the two convex prisms 16 are symmetrically arranged on both sides of the inner hole. Slot 17.

Embodiment 3

[0038] refer to Figure 5 , this embodiment is basically the same as the second embodiment, the difference is that the nail tip of the ratchet nail 8 is inclined toward the direction of the injection rod to prevent withdrawal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com