High-temperature dust collection-desulfurization-denitrification integrated device and method of using same

A technology for desulfurization, denitrification, and high-temperature dust removal, which is applied in chemical instruments and methods, separation methods, transportation and packaging, etc. It can solve the problems of reducing denitrification efficiency, generating waste water, and affecting catalyst activity, and achieves the effect of increasing desulfurization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

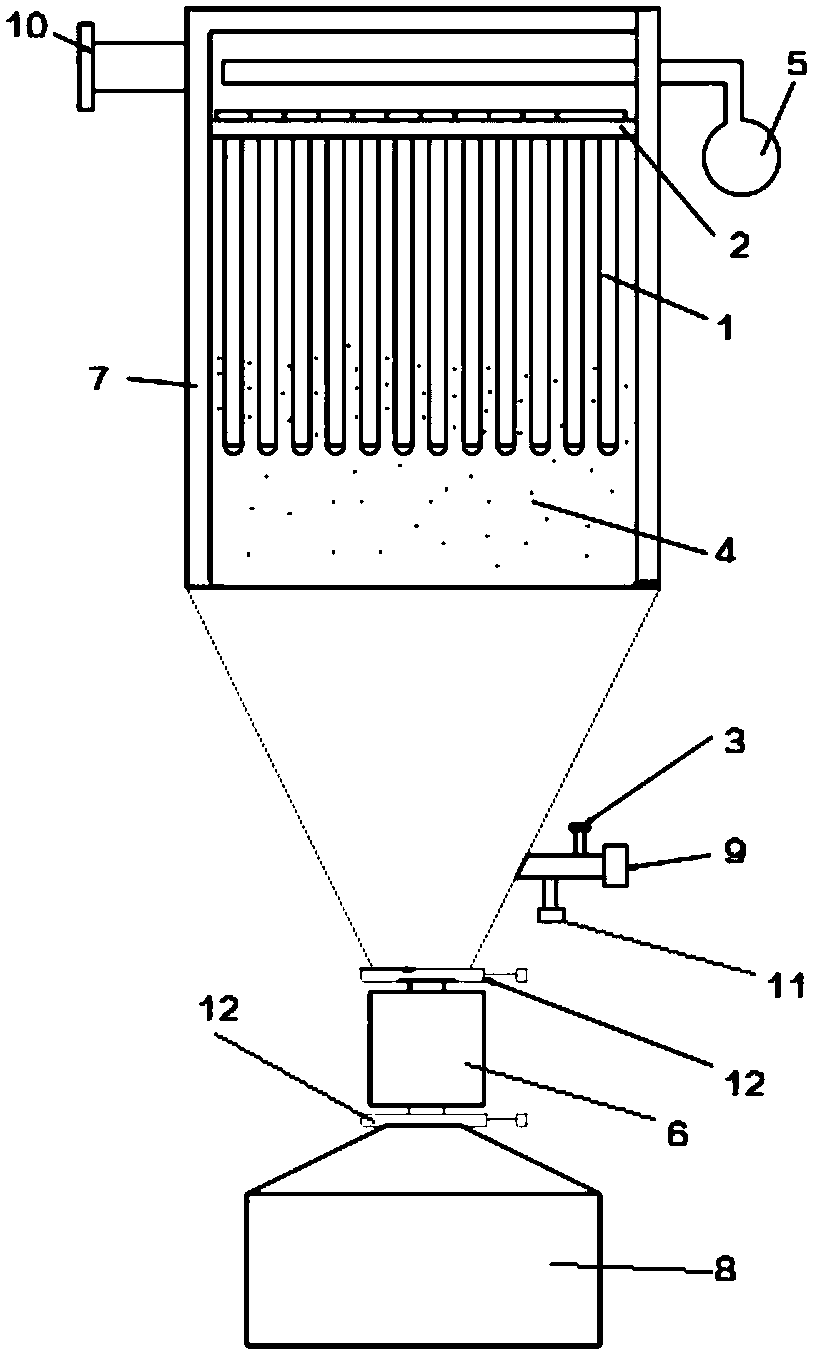

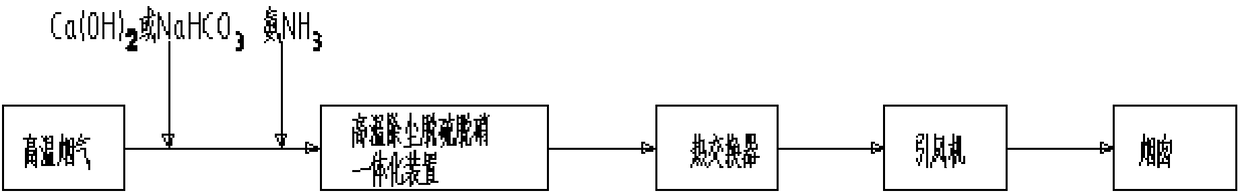

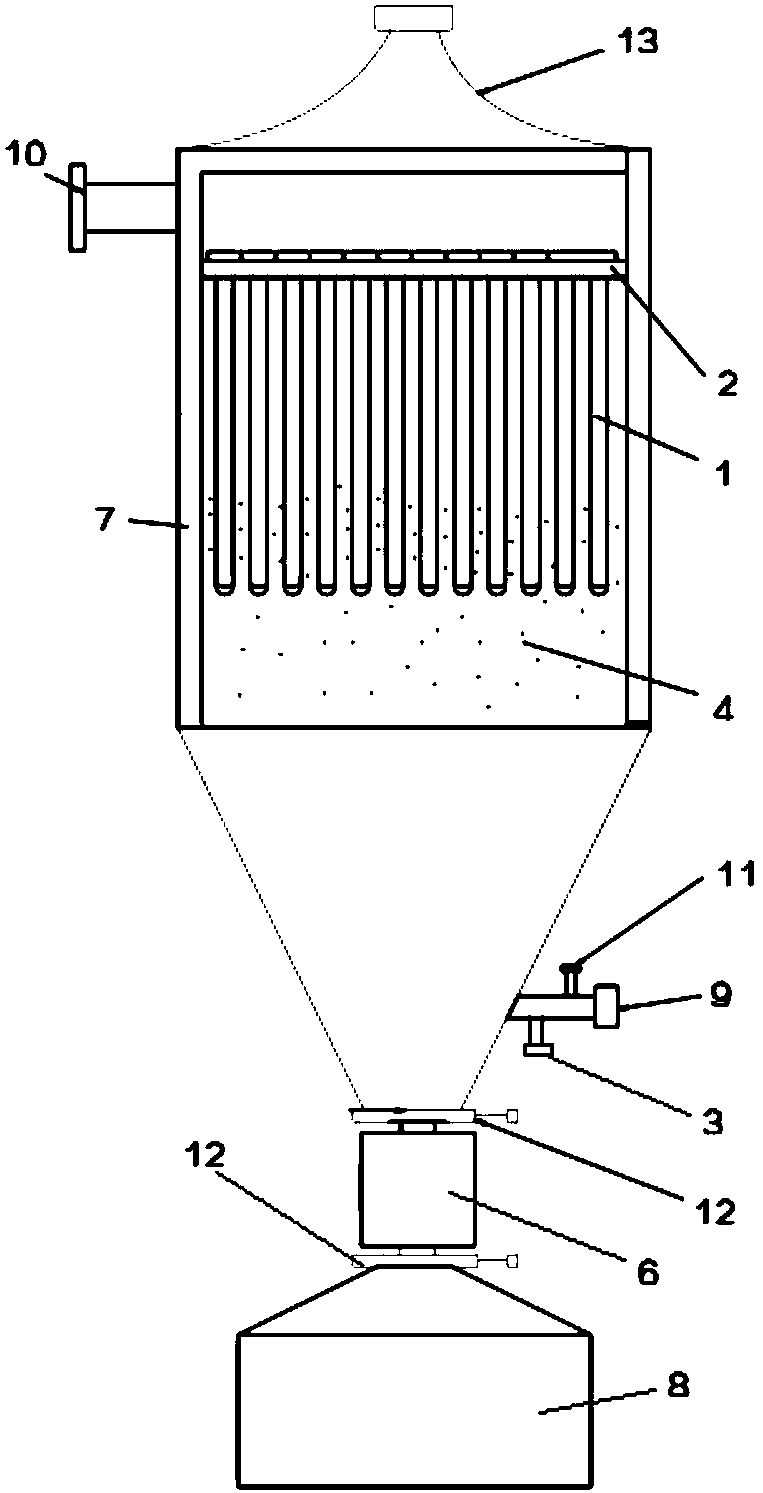

[0029] Such as figure 1 As shown, this embodiment provides a high-temperature dust removal, desulfurization and denitrification integrated device, including a housing 7, a high-temperature flue gas inlet 9 is provided at the lower part of the housing 7, and a clean flue gas outlet 10 is provided at the upper part of the housing 7. There are multiple sets of filter elements 1 inside the housing 7 and between the high-temperature flue gas inlet 9 and the clean flue gas outlet 10; A medicament injection port 11 and a gas injection port 3; a dust collection bin 8 is provided at the bottom of the housing 7; a pulse cleaning device 5 is provided at the upper part of the housing 7.

[0030] In this specific example, if figure 1 , 2 As shown in and 4 , an intermediate collection bin 6 is arranged between the housing 7 and the dust bin 8 . Knife gate valves 12 are provided between the intermediate collection bin 6 and the housing 7 and between the intermediate collection bin 6 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com