Pipeline catalytic reactor for liquid phase

A catalytic reaction and pipeline technology, applied in chemical/physical processes, chemical instruments and methods, etc., can solve the problems of insufficient reaction of liquid phase reactants, short catalyst contact time, increased equipment cost, etc., and achieve scientific and reasonable stage number setting, Short reaction time, easy to manufacture and realize the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

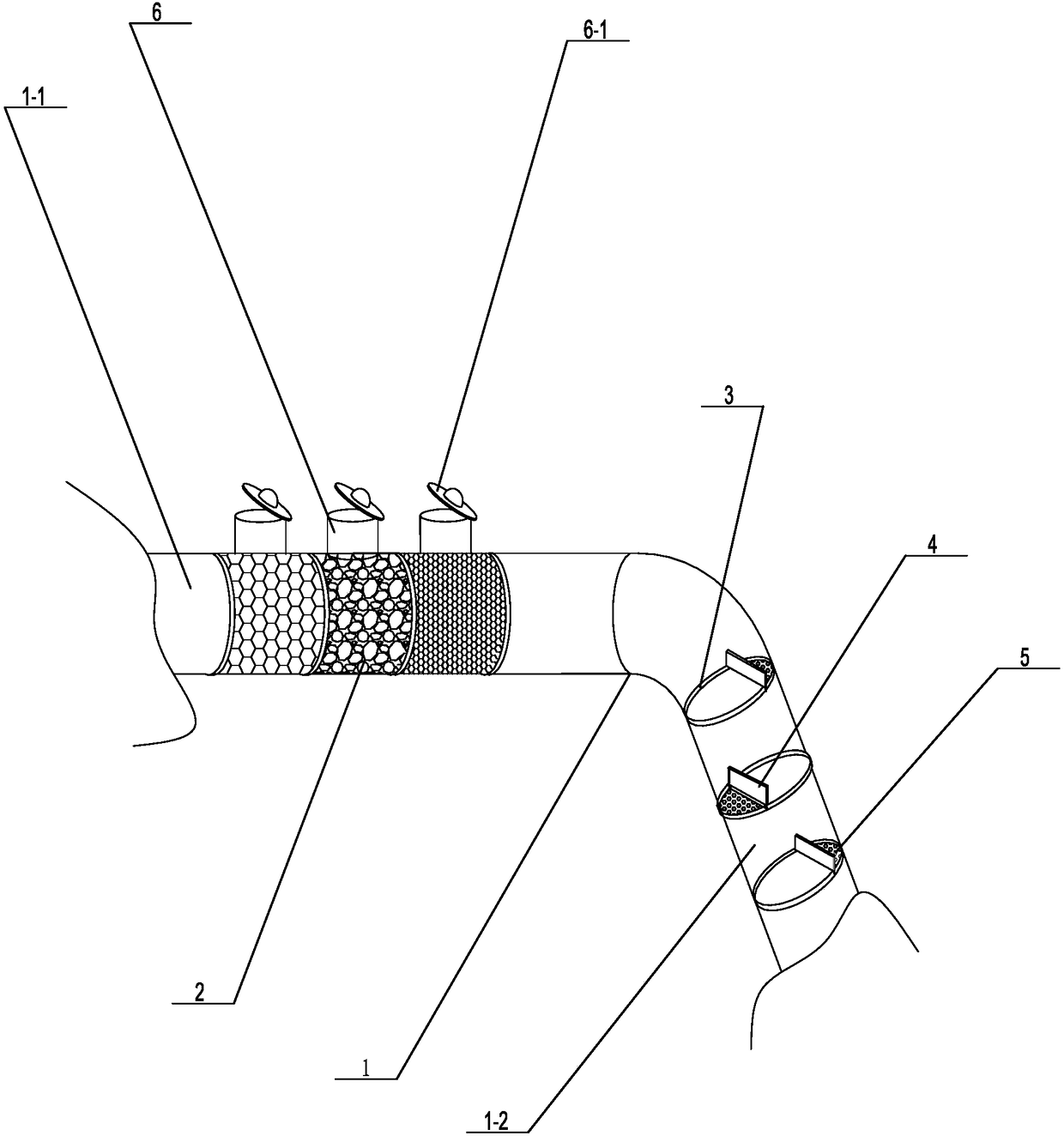

[0017] Such as figure 1 Propose a kind of specific embodiment of the present invention as shown, the pipeline catalytic reaction device that liquid phase is used, comprise reaction pipeline 1, described reaction pipeline 1 comprises the deceleration branch pipe 1-1 that horizontally arranges and the reaction branch pipe 1-1 that obliquely arranges downwards 2. The front end of the deceleration branch pipe 1-1 is connected to the liquid phase reactant delivery system, and the rear end of the reaction branch pipe 1-1 is connected to the product return system. In this embodiment, the deceleration branch pipe 1-1 and the reaction branch pipe 1-2 are set. Both are cylindrical and hollow with equal diameters, and in order to ensure the strength of the entire reaction pipeline, the reaction branch pipe 1-1 and the reaction branch pipe 1-2 are integrally formed; the deceleration branch pipe 1-1 is provided with several sections of ceramic ball joints 2, The ceramic ball joints 2 are a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com