Tungsten target material welding method and tungsten target material assembly

A welding method and target technology, applied in welding equipment, welding/welding/cutting items, manufacturing tools, etc., can solve the problems of low welding success rate, poor weld uniformity, and poor welding stability, and improve the welding success rate. , The effect of reducing welding deformation and improving welding stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

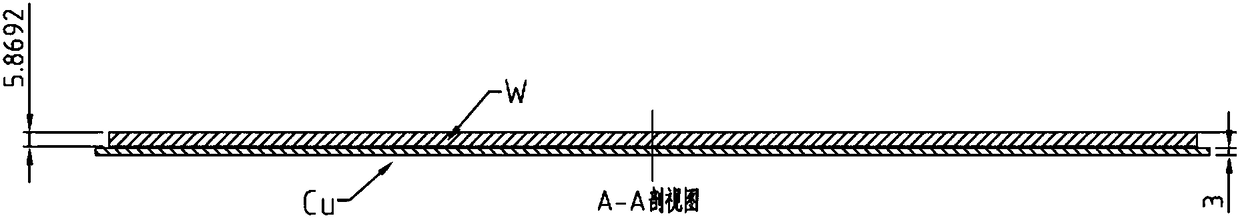

[0027] The applicant found that in the existing tungsten target welding method, the tungsten material and the back plate material must be welded together to be processed into the target material used for the semiconductor, and the thickness of the commonly used back plate is relatively thin, which is easy to It causes large welding deformation during welding, which affects the use effect of tungsten targets. Please refer to figure 1 , figure 1 A schematic structural view of a tungsten target produced by a traditional tungsten target welding method is shown. Among them, the tungsten target is the back plate of the sputtering target, that is, the material used as the cathode in the sputtering deposition technology. The cathode material is detached in the form of molecules, atoms or ions under the impact of positively charged cations in the sputtering machine. Cathode redeposited on the surface of the anode. Since the metal sputtering target is often a relatively expensive mat...

no. 2 example

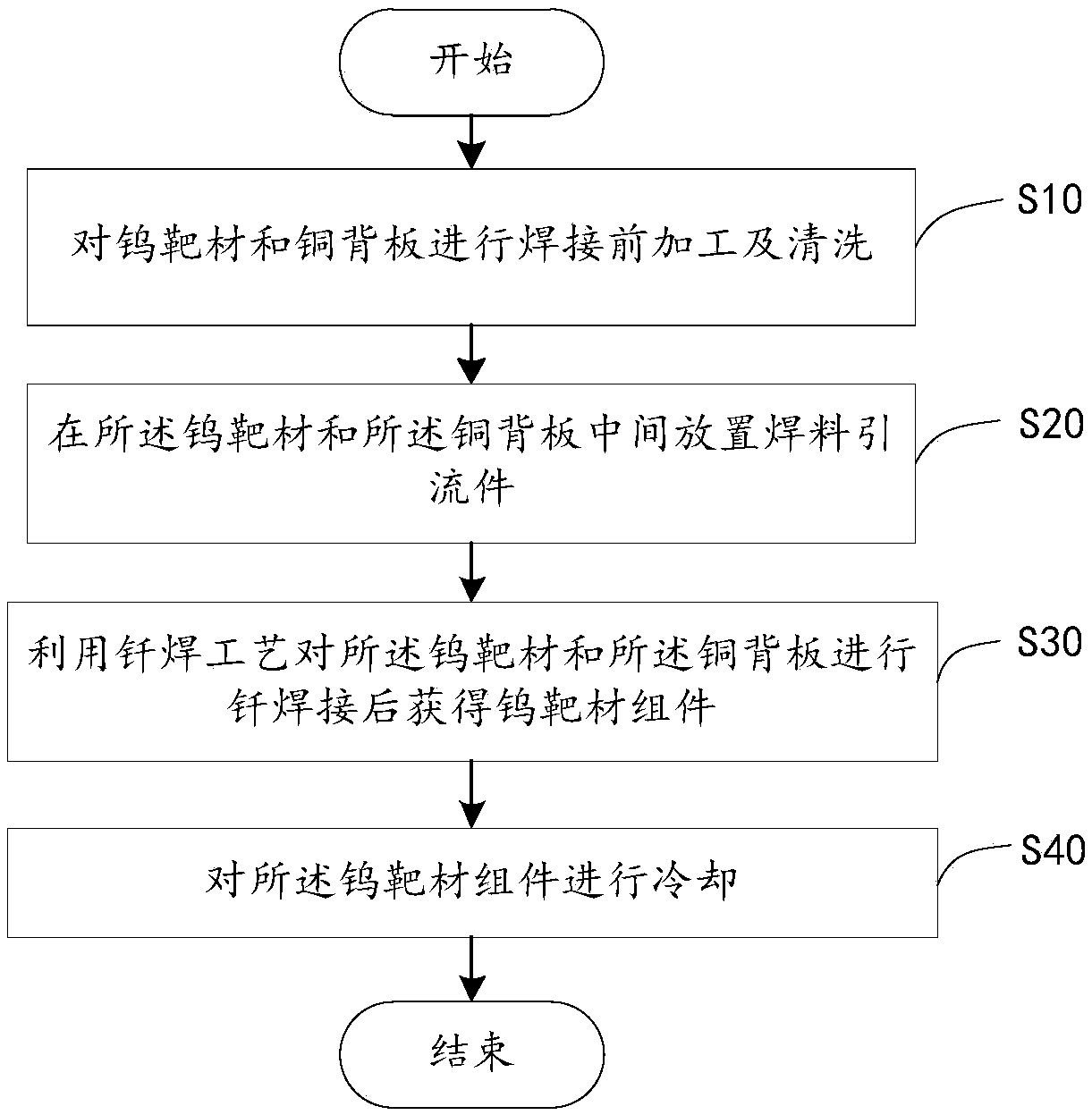

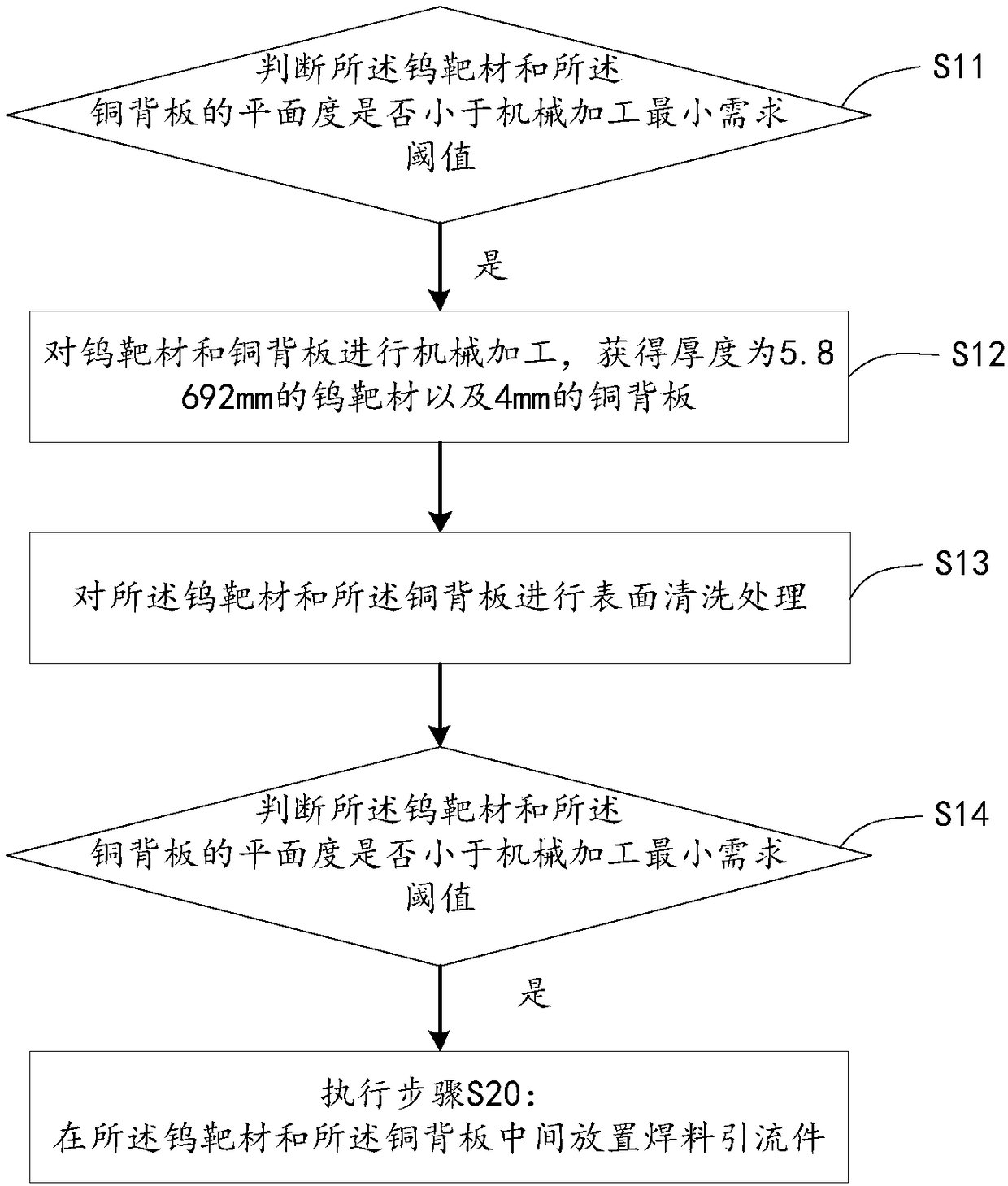

[0046] Please refer to Figure 4 , Figure 4 It is a flow chart of another tungsten target welding method provided by the second embodiment of the present invention. The specific steps of the tungsten target welding method provided in this embodiment are as follows:

[0047] Step S10: Processing and cleaning the tungsten target and the copper back plate before welding, engraving threads on the welding surface of the copper back plate when processing the copper back plate before welding;

[0048] Step S20: placing a solder drain piece between the tungsten target and the copper back plate.

[0049] Step S30: using a brazing process to braze the tungsten target and the copper back plate to obtain a tungsten target assembly.

[0050] Step S40: cooling the tungsten target assembly.

[0051] Different from the tungsten target welding method provided in the first embodiment of the present invention, step S10 of the tungsten target welding method provided in this embodiment engrav...

no. 3 example

[0053] Please refer to Figure 5 , Figure 5 It is a schematic structural diagram of a tungsten target assembly provided by the third embodiment of the present invention.

[0054] It should be understood that the present invention also provides a tungsten target assembly made by using the tungsten target welding method of the present invention. The thickness of the tungsten target part of the tungsten target assembly is 5.8692 mm, and the flatness is 0.1 mm; the thickness of the copper back plate part of the tungsten target assembly is 4 mm, and the flatness is 0.2 mm.

[0055] To sum up, the embodiment of the present invention provides a tungsten target welding method and a tungsten target assembly. The tungsten target welding method combines the tungsten target and the copper back plate before welding the tungsten target and the copper back plate. At least one copper wire is placed in the middle of the copper back plate to make the solder distribution between the tungsten ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com