Flame-retarding and smoke-suppressing polypropylene composite material and preparation method thereof

A composite material, polypropylene technology, used in the field of flame retardant composite materials, can solve the problems of unreachable heat release, low mechanical properties of polypropylene, and degradation of plastic properties, avoiding the release of heat and airflow through the carbon layer, improving Effect of char formation rate, enhanced stability and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

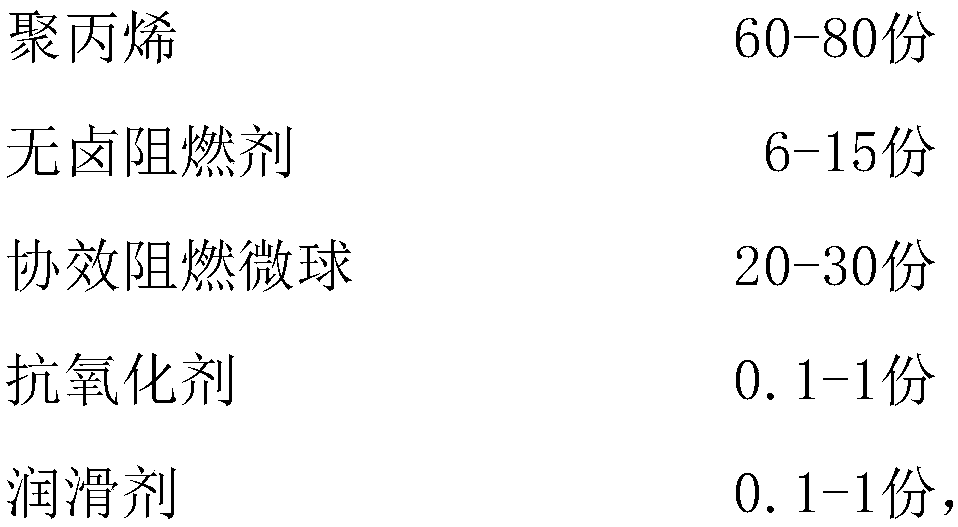

[0036] A flame-retardant and smoke-suppressing polypropylene composite material, comprising the following raw materials in parts by weight:

[0037]

[0038]

[0039] The preparation method of the synergistic flame retardant microspheres comprises the following steps:

[0040] A. After mixing 4.5 parts by weight of zinc stannate hexahydrate, 6 parts by weight of tin tetrachloride pentahydrate and 2 parts by weight of nanocellulose, add an appropriate amount of water, carry out ultrasonic dispersion, heat up for hydrothermal reaction, and take out Precipitation, repeated washing with deionized water, drying, and roasting to obtain porous zinc stannate;

[0041] B. At a temperature of 80°C, dissolve microcrystalline cellulose in 1-methyl 3-butylimidazolium chloride ionic liquid at a mass ratio of 7:100 to form a microcrystalline cellulose solution, and then add the obtained product in step A Porous zinc stannate obtains a suspension, wherein the consumption of the porous zi...

Embodiment 2

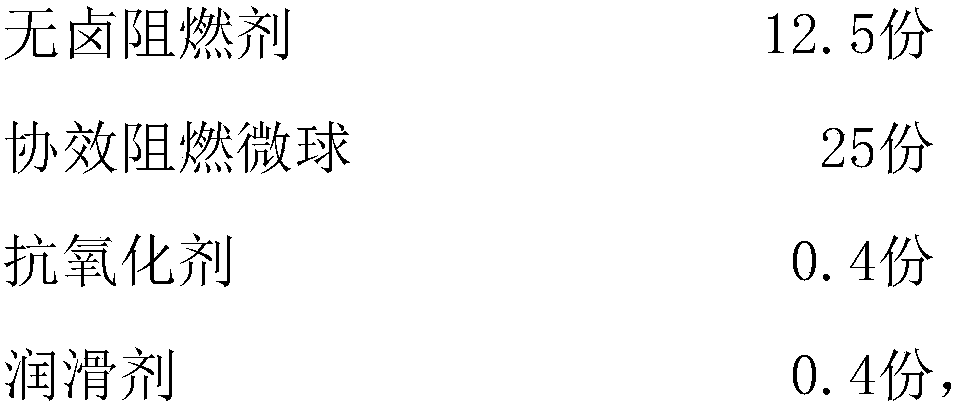

[0054] A flame-retardant and smoke-suppressing polypropylene composite material, comprising the following raw materials in parts by weight:

[0055]

[0056] The preparation method of the synergistic flame retardant microspheres comprises the following steps:

[0057] A. After mixing 3 parts by weight of zinc stannate hexahydrate, 4 parts by weight of tin tetrachloride pentahydrate and 1 part by weight of nanocellulose, add an appropriate amount of water, carry out ultrasonic dispersion, heat up for hydrothermal reaction, and take out Precipitation, repeated washing with deionized water, drying, and roasting to obtain porous zinc stannate;

[0058] B. At a temperature of 70°C, dissolve microcrystalline cellulose in 1-methyl 3-butylimidazolium chloride ionic liquid in a mass ratio of 4:100 to form a microcrystalline cellulose solution, and then add the obtained product in step A Porous zinc stannate obtains a suspension, wherein the consumption of the porous zinc stannate i...

Embodiment 3

[0071] A flame-retardant and smoke-suppressing polypropylene composite material, comprising the following raw materials in parts by weight:

[0072]

[0073] The preparation method of the synergistic flame retardant microspheres comprises the following steps:

[0074] A. After mixing 6 parts by weight of zinc stannate hexahydrate, 8 parts by weight of tin tetrachloride pentahydrate and 3 parts by weight of nanocellulose, add an appropriate amount of water, carry out ultrasonic dispersion, heat up for hydrothermal reaction, and take out Precipitation, repeated washing with deionized water, drying, and roasting to obtain porous zinc stannate;

[0075] B. At a temperature of 90°C, dissolve microcrystalline cellulose in 1-methyl 3-butyl imidazolium chloride ionic liquid in a mass ratio of 10:100 to form a microcrystalline cellulose solution, and then add the obtained product in step A Porous zinc stannate obtains a suspension, wherein the consumption of the porous zinc stannat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com