Torsion vibration absorber with piecewise linear rods

A piecewise linear vibration absorber technology, which is applied in the direction of rotation vibration suppression, can solve the problems of narrow vibration suppression frequency band, unchangeable structural parameters, and reduced reliability of vibration absorbers, and achieves expanded operating frequency range, compact structure, and vibration suppression. The effect of bandwidth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

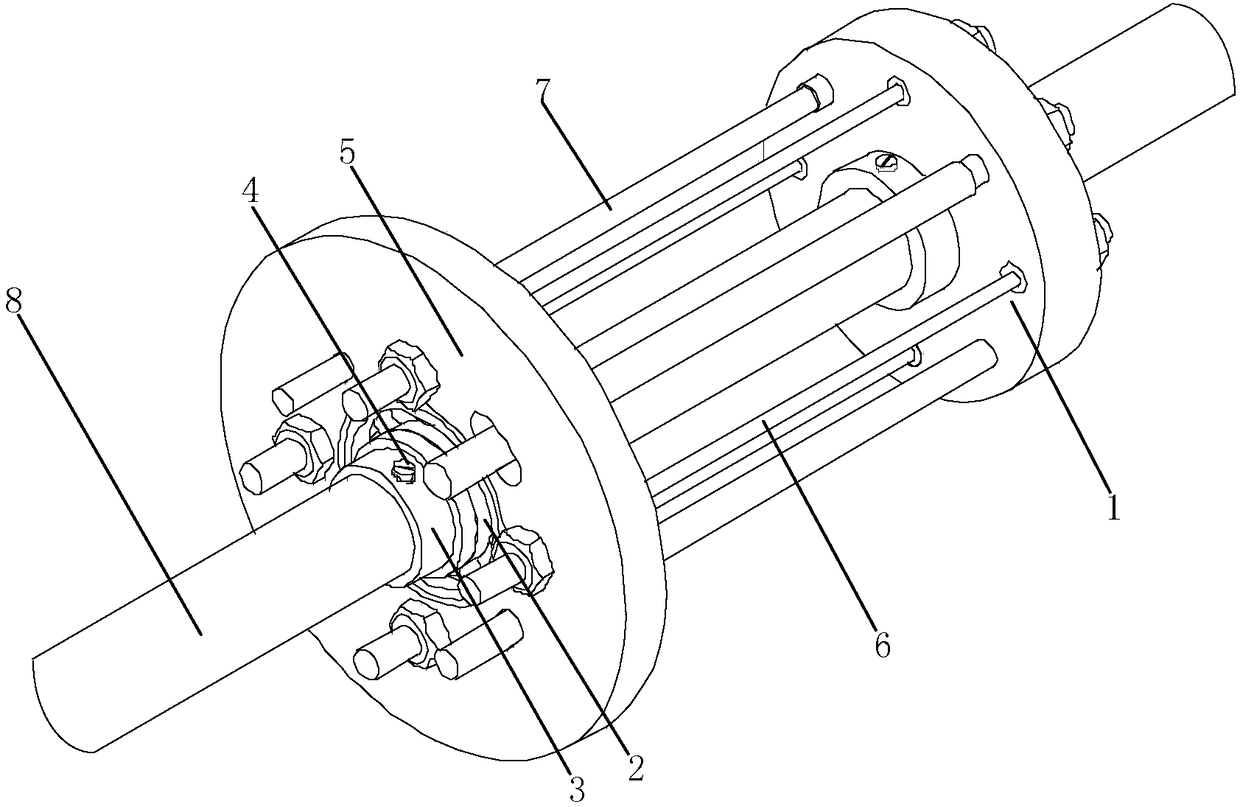

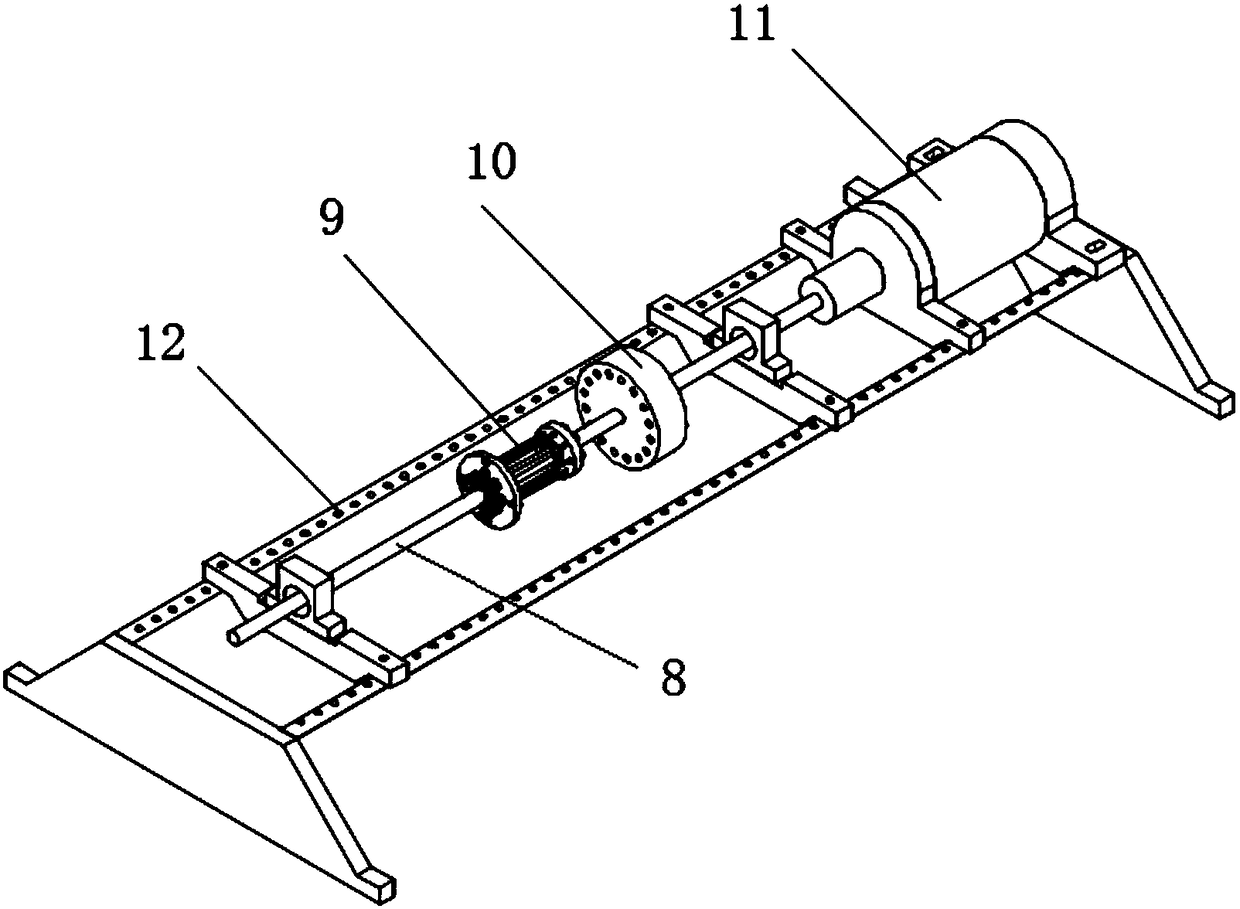

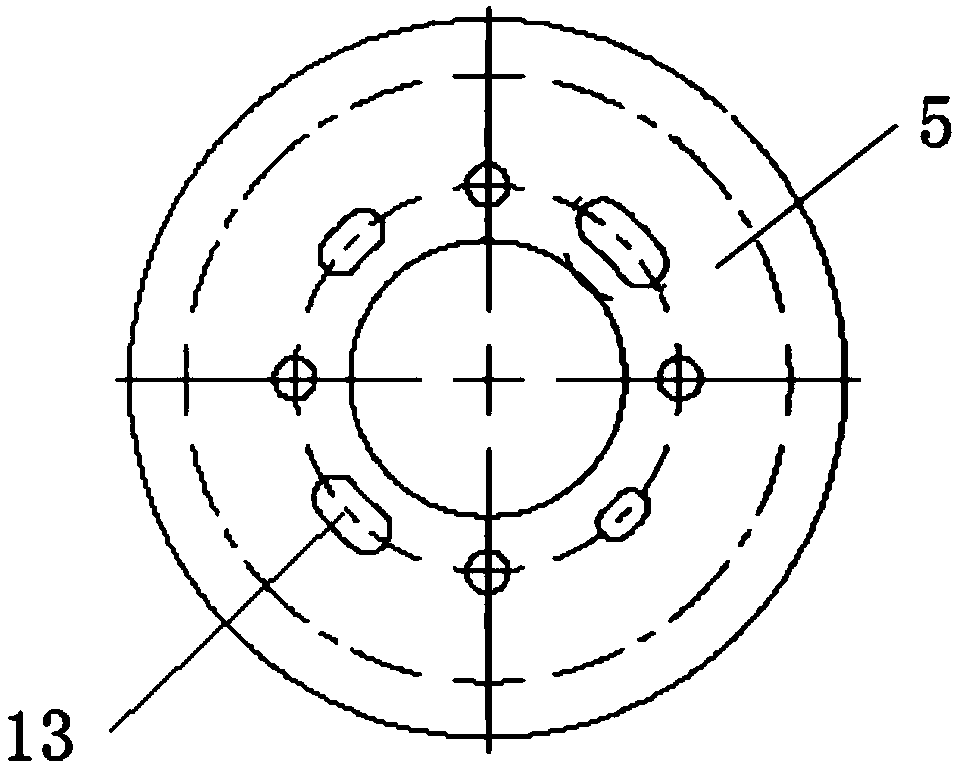

[0023] like Figure 1-3 As shown, a torsional vibration absorber with a segmented linear rod includes a support plate 1, a bearing 2, a bushing 3, a fastening screw 4, a connecting rod 6, a segmented linear rod 7 and a vibration-absorbing mass 5, the The support plate 1 is a disc structure, and the support plate 1 is fixedly connected to the rotor 8; the vibration-absorbing mass 5 is a disc structure, and the vibration-absorbing mass 5 is provided with a central hole and four grooves uniformly distributed around the circumference Arc slots 13 with different mouth widths and arc angles; the bearing 2 is installed in the center hole and fitted on the rotor 8, and the bushing 3 is installed on the rotor 8 through fastening screws 4 to the rotor 8. The bearing 2 is positioned; the support disc 1 is fixedly connected to the vibration-absorbing mass 5 through the connecting rod 6; the segmented linear rod 7 is four rigid rods with different diameters, and the segmented linear rod 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com