A method for testing the normal strength between layers of composite materials

A composite material layer and composite material technology, applied in the field of composite material interlayer normal strength test method and the design and manufacture of test pieces, can solve the problems of easy damage, low interlayer performance, inaccurate measured performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

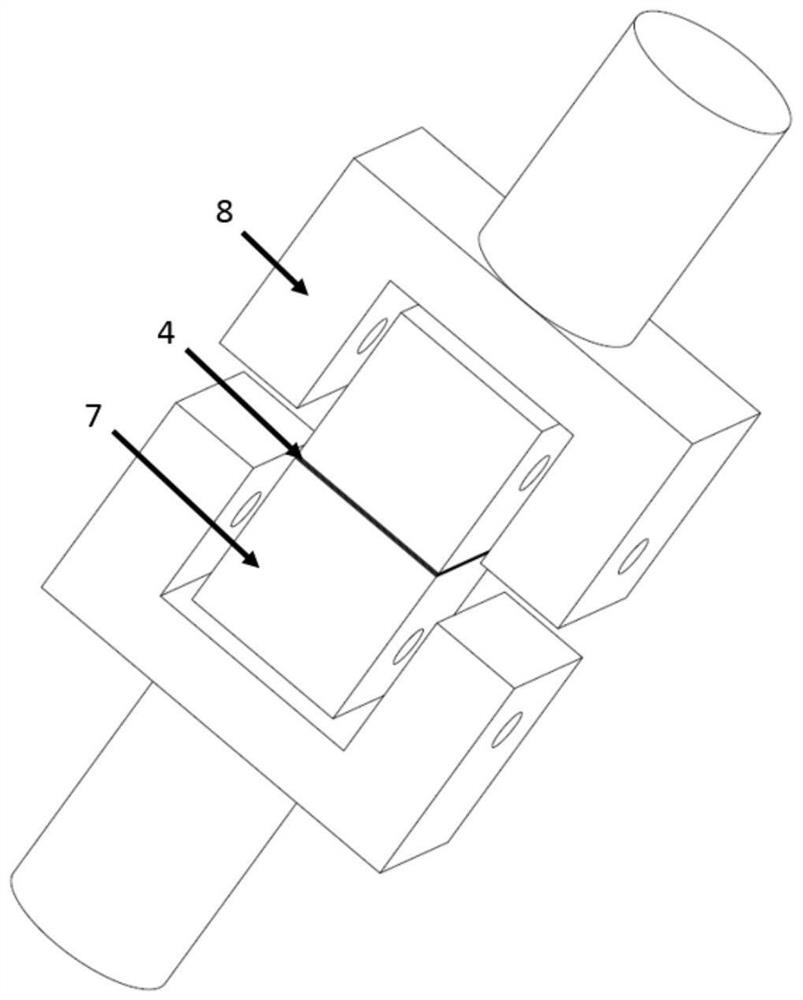

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0025] The invention provides a method for testing the interlaminar normal strength of a composite material, said test method comprising the following steps:

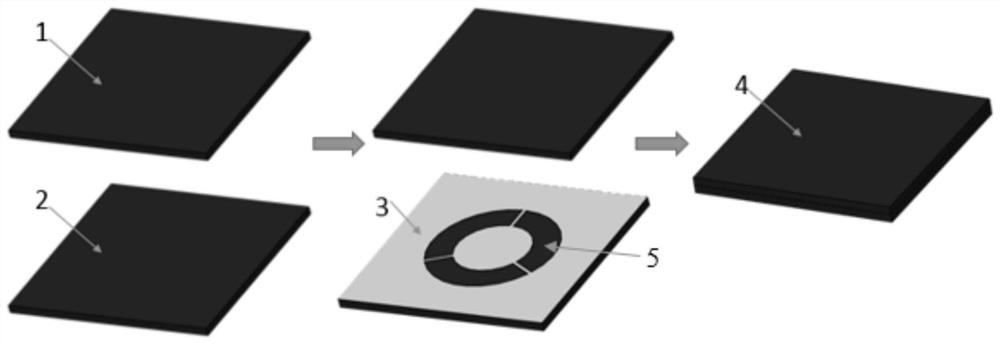

[0026] In the first step, the thin film is prepared.

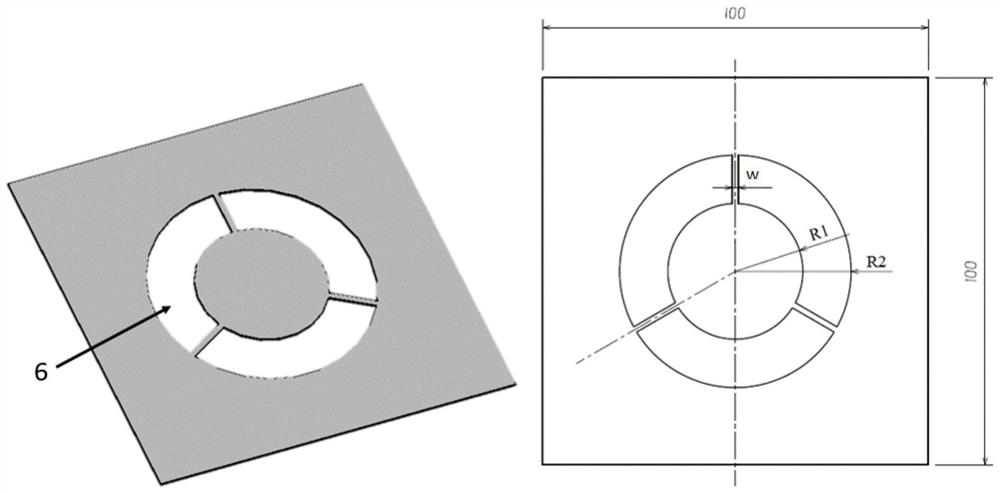

[0027] The film is made of 100mm×100mm square polytetrafluoroethylene material. The thickness of the film should be thin enough under the premise that the process allows, which can not only ensure the integrity of the film during the preparation process, but also ensure that the interface strength on both sides of the hollowed out area is not weakened, usually the theoretical thickness of the single layer of the composite material to be measured about 20%. The film contains an annular hollow area, which corresponds to the composite test area. Such as figure 1 and figure 2 As shown, the inner and outer diameters R of the hollowed out area 1 , R 2 An...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com