Bionic bone sample for terahertz in-situ impact testing and preparation method thereof

A technology for impact testing and samples, which is applied in the preparation of test samples, the use of one-time impact force to test the strength of materials, and measurement devices, etc. It can solve the problems of inability to obtain experimental data, experimental data that cannot clearly reflect the impact performance of natural bone, and samples that cannot A large number of preparations and other issues, to achieve the effect of simplifying the fine structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

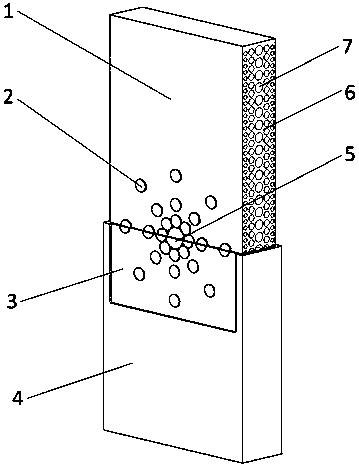

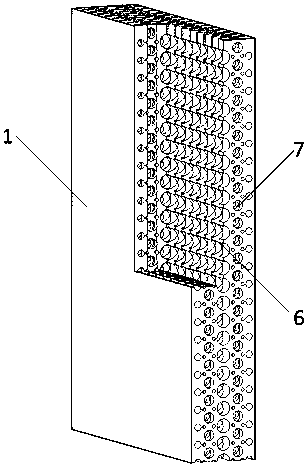

[0044] refer to Figure 1 to Figure 4 As shown, the bionic bone sample used in the terahertz in-situ impact test according to the present invention has a main body size of 120 mm × 60 mm × 10 mm, which is suitable for medium and large impact performance testing equipment.

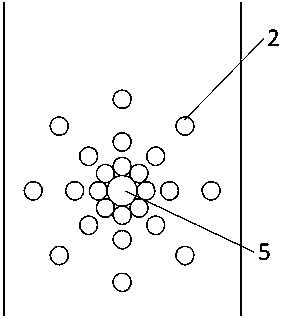

[0045]The sample of the present invention utilizes 3D printing technology to adopt a manufacturing method of printing from the inside out and layer by layer. According to the data of related papers, the natural cancellous bone has the following rules: along the centerline of the columnar bone horizontally outward until the compact bone, the porosity of the cancellous bone gradually decreases; on the contour section parallel to the centerline of the columnar bone , the value of porosity remains basically unchanged. Propose a parabolic fitting for the porosity of cancellous bone, analyze the fine structure, physical properties and mechanical properties of the natural bone studied in the experiment, simplify ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com