End surface quenching test device of hardenability of aluminum alloy, and method thereof

A testing device and hardenability technology, applied in testing metals, investigation stage/state change, material inspection products, etc., can solve problems such as difficulty in accurately meeting test requirements, lack of uniformity, poor parameter comparability, etc., to reduce experimental costs, High accuracy and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The idea, specific structure and technical effects of the present invention will be further described below in conjunction with the accompanying drawings, so as to fully understand the purpose, features and effects of the present invention.

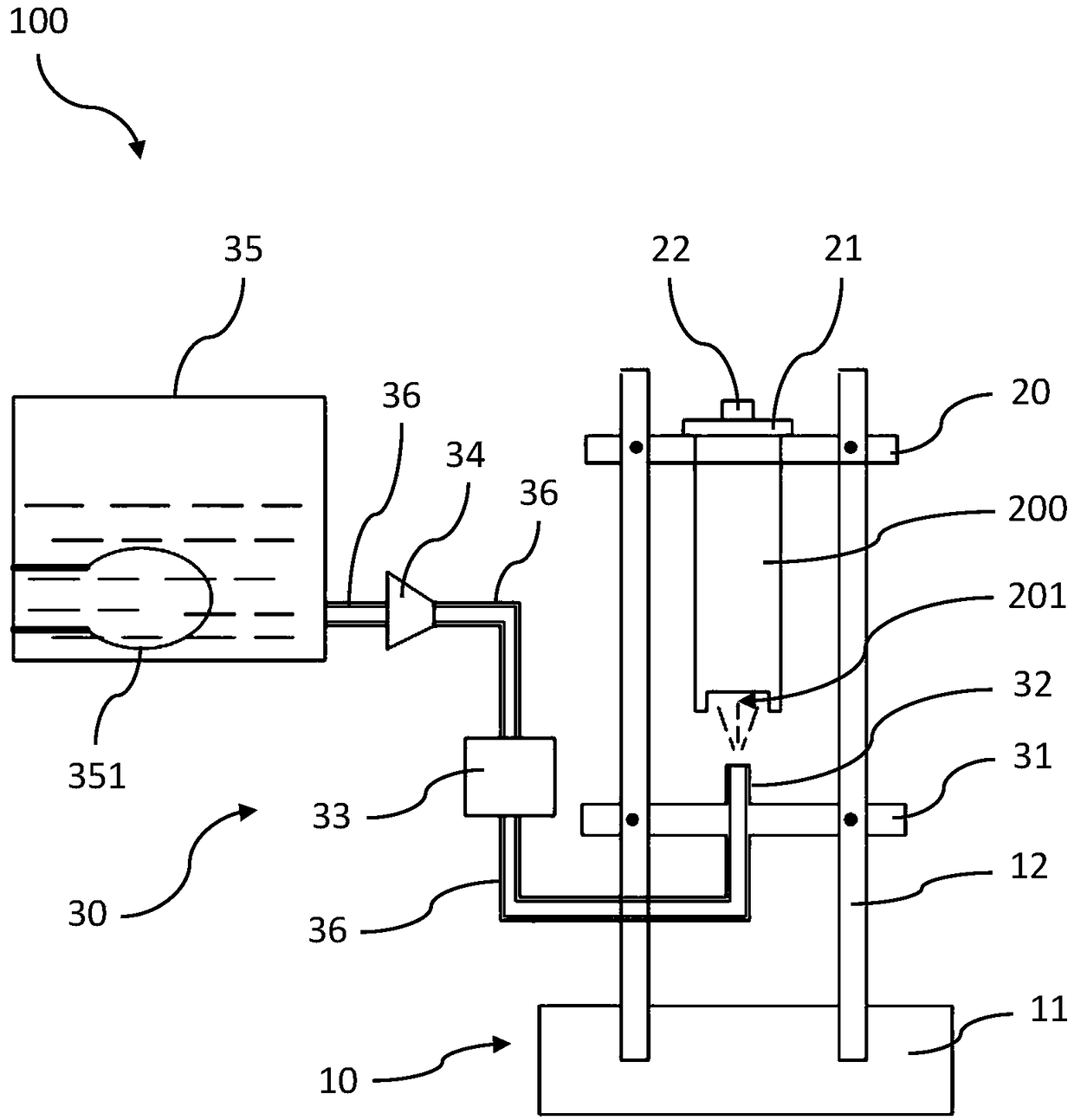

[0037] figure 1 It is a structural schematic diagram of an end face quenching test device for aluminum alloy hardenability in an embodiment of the present invention.

[0038] In this example, if figure 1 As shown, the sample rod 200 is made of aluminum alloy material, and is a rectangular parallelepiped with a square cross section. The dimensions of the rectangular parallelepiped are 25mm long, 25mm wide, and 125mm high. The upper end of the sample rod 200 is used as a fixed end, and a screw hole (not shown) for fixing is provided on it, and the size of the threaded hole is 5 mm in diameter and 15 mm deep; the lower end of the sample rod 200 is used as a quenching end, and its A cylindrical groove 201 is provided on the top, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com