Lithium-sulfur battery anode material and application thereof

A positive electrode material, lithium-sulfur battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of complex process and expensive equipment, and achieve the effect of improving conductivity, suppressing volume expansion effect, and excellent electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

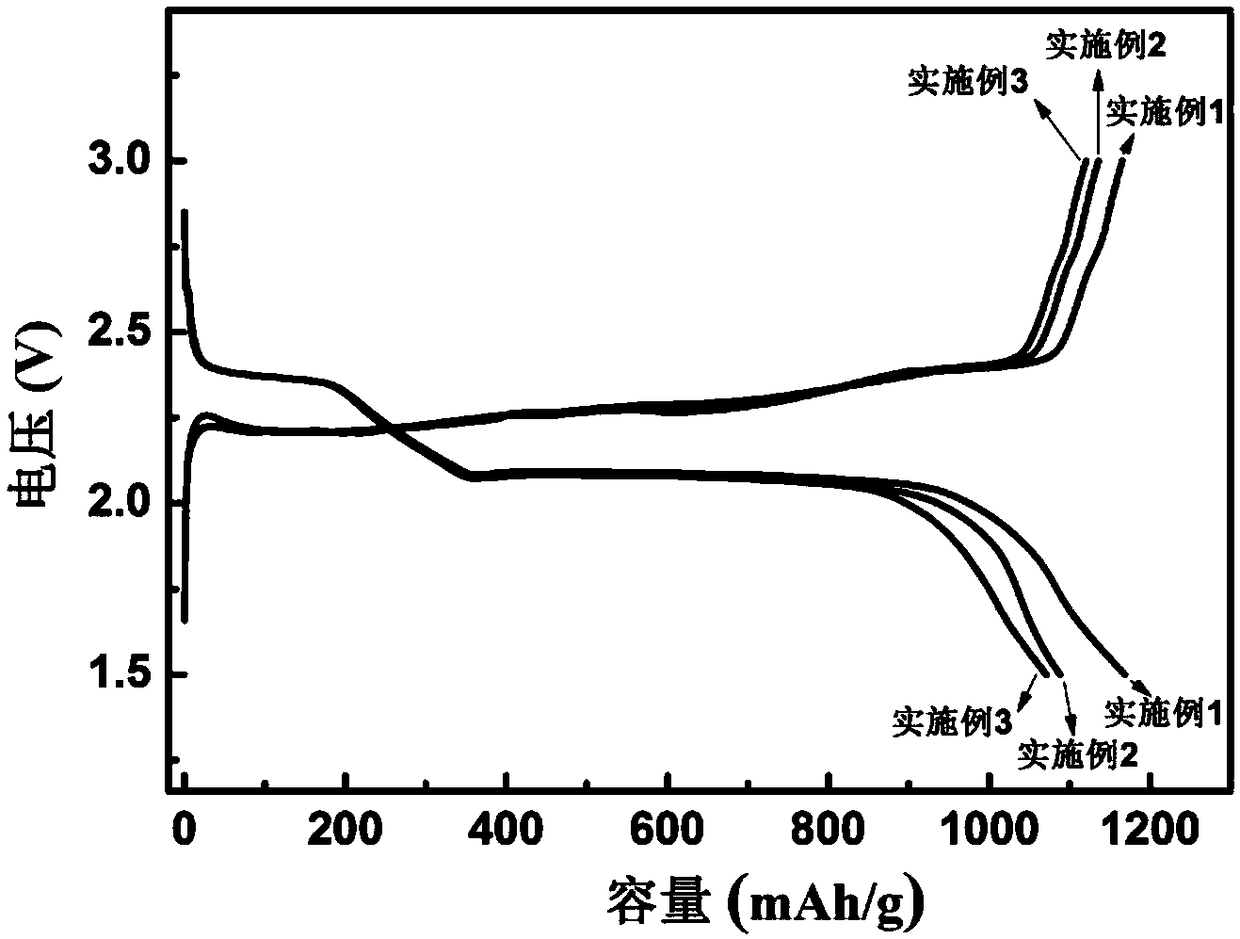

Embodiment 1

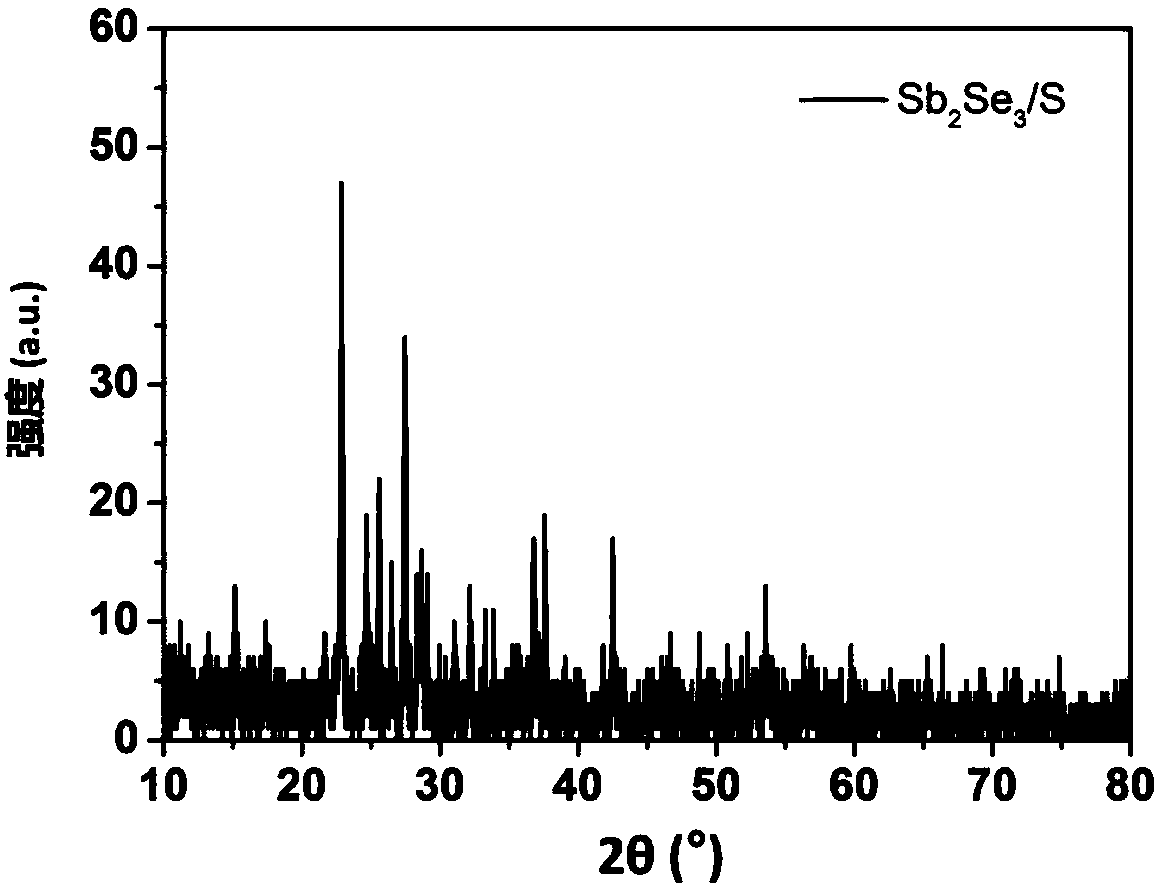

[0026] The first step is to prepare antimony selenide (Sb 2 Se 3 )Nano stave:

[0027] Dissolving antimony trichloride in triethylene glycol, stirring for 30 minutes, to obtain a cationic solution; then dissolving selenium powder in the first mixed solution, stirring for 30 minutes, to obtain a selenium precursor solution; Pour it into the second mixed solution, divide it under nitrogen, and stir at 200°C for 30 minutes; then continue to stir the cationic solution for 20 minutes, then cool it to room temperature, and centrifuge it with a high-speed centrifuge for 10 minutes to finally obtain pure Sb 2 Se 3 Antimony Selenide Nanorods. Wherein, every 5mL triethylene glycol adds 1mmol antimony trichloride; The composition of the first mixed solution is monoethanolamine and N 2 h 4 ·H 2 O, the volume ratio of the two is 4:1, and 1.5mmol selenium powder is added in the first mixed solution of every 1.5mL; The composition of the second mixed solution is the triethylene glycol...

Embodiment 2

[0036] The first step is to prepare antimony selenide (Sb 2 Se 3 )Nano stave:

[0037] Dissolving antimony trichloride in triethylene glycol, stirring for 30 minutes, to obtain a cationic solution; then dissolving selenium powder in the first mixed solution, stirring for 30 minutes, to obtain a selenium precursor solution; Pour it into the second mixed solution, divide it under nitrogen, and stir at 200°C for 30 minutes; then continue to stir the cationic solution for 20 minutes, then cool it to room temperature, and centrifuge it with a high-speed centrifuge for 10 minutes to finally obtain pure Sb 2 Se 3 Antimony Selenide Nanorods. Wherein, every 5mL triethylene glycol adds 1mmol antimony trichloride; The composition of the first mixed solution is monoethanolamine and N 2 h 4 ·H 2 O, the volume ratio of the two is 4:1, and 1.5mmol selenium powder is added in the first mixed solution of every 1.5mL; The composition of the second mixed solution is the triethylene glycol...

Embodiment 3

[0044] The first step is to prepare antimony selenide (Sb 2 Se 3 )Nano stave:

[0045] Dissolving antimony trichloride in triethylene glycol, stirring for 30 minutes, to obtain a cationic solution; then dissolving selenium powder in the first mixed solution, stirring for 30 minutes, to obtain a selenium precursor solution; Pour it into the second mixed solution, divide it under nitrogen, and stir at 200°C for 30 minutes; then continue to stir the cationic solution for 20 minutes, then cool it to room temperature, and centrifuge it with a high-speed centrifuge for 10 minutes to finally obtain pure Sb 2 Se 3 Antimony Selenide Nanorods. Wherein, every 5mL triethylene glycol adds 1mmol antimony trichloride; The composition of the first mixed solution is monoethanolamine and N 2 h 4 ·H 2 O, the volume ratio of the two is 4:1, and 1.5mmol selenium powder is added in the first mixed solution of every 1.5mL; The composition of the second mixed solution is the triethylene glycol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com