Directly-driven centrifugal separation device

A centrifugal separation and direct-drive technology, applied to centrifuges with rotating drums, centrifuges, etc., can solve the problems of complex manufacturing process, inability to clean solids on-line, and inability to feed materials on-line

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0183] The driving system of this embodiment is an external rotor motor, and its detailed structural diagram is shown in the attached Figure 6 .

[0184] as attached Figure 6 Shown, centrifugal turntable (6-9) and centrifugal bowl (6-4) are independent parts. The independent top cover (6-1) that seals the centrifuged liquid collection chamber (6-17) is fixed on the top of the chamber wall (6-3) of the centrifuged liquid collection chamber by its top cover fixing structure (6-25), and passes through the door The lock (6-26) is locked tightly; the center of the top cover has a feeding hole. The drum top cover (6-27) of the sealed centrifugal drum, the turntable connection structure (6-6) located outside the bottom of the centrifugal drum (6-4) and the centrifugal drum body are integrally formed; the centrifugal drum Connect and fix with the drum connection structure (6-18) located outside the centrifugal turntable (6-5) through the turntable connection structure located at ...

Embodiment 2

[0189] In this embodiment, the drive system is an external rotor motor, and its detailed structural diagram is shown in the attached Figure 7 .

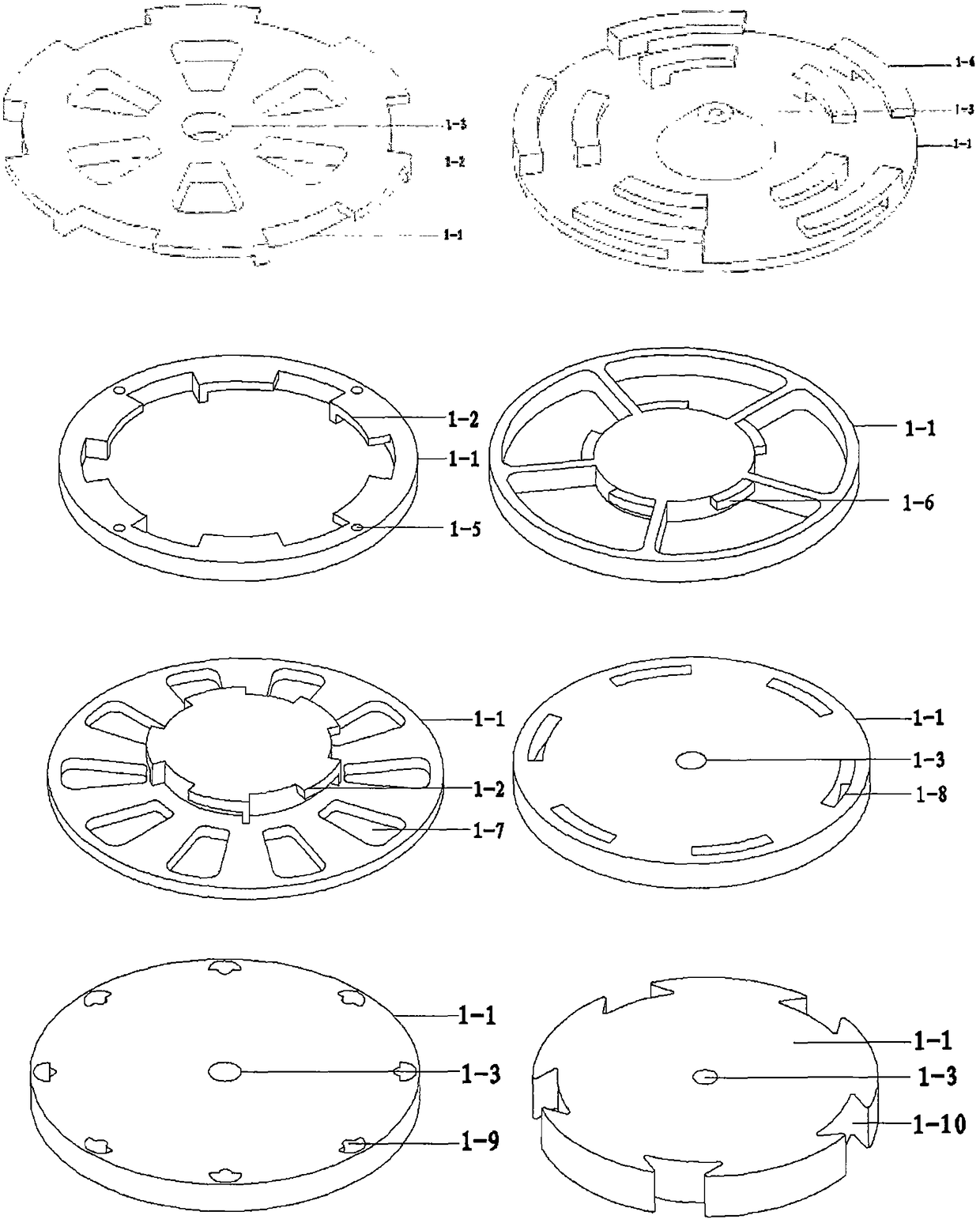

[0190] as attached Figure 7 As shown, the independent top cover (7-1) of the sealed centrifuged liquid collection chamber (7-6) is connected to the connection structure 1 (7-2) on the top of the centrifuged liquid collection chamber wall through the connecting structure 2 (7-3) on its outside. ) to rotate and lock each other to fix the top cover (see the attachment for the connection structure Picture 1-1 and attached Pic 4-1 ); the center of the top cover has a feeding hole; the drum top cover (7-22) of the sealed centrifugal drum passes through the connecting structure 4 (7- 25) Mutual rotation and clamping to realize the fixation of the top cover (connection structure see attached Figure 1-2 and attached Pic 4-1 ).

[0191] as attached Figure 7 As shown, the cooling coil (7-4), the base (7-11), the stator assembly (7-1...

Embodiment 3

[0195] In this embodiment, the drive system is an inner rotor motor, and its detailed structural diagram is shown in the attached Figure 8 .

[0196] as attached Figure 8 As shown, the connection mode between the top cover (8-1) of the sealed centrifugal liquid collection chamber and the cavity wall is the same as that of embodiment 2; the connection mode between the centrifugal drum and the drum top cover of the sealed centrifugal drum is the same as that of embodiment 2; The circular hole in the center of the top cover that seals the centrifuged liquid collection chamber is the feeding hole (8-9) for the solid-liquid mixture to be centrifuged.

[0197] as attached Figure 8 As shown, the cooling coil (8-2), the stator assembly (8-7) and the front end cover (8-8) are integrally molded with a plastic sealant to form the cavity wall of the centrifugal liquid collection cavity, and the center of the bottom is respectively surrounded by a The circular cavity on the outside a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com