Method for adjusting surface luminosity of mold on basis of laser-engraving technique

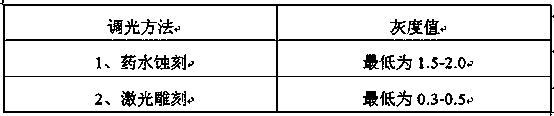

A technology of surface luminosity and laser engraving, applied in the field of texture processing, which can solve problems such as insufficient uniformity, easy rebound of luminosity, limited range of luminosity adjustment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] A method for adjusting the brightness of the mold surface based on laser engraving technology. First, a set of texture grayscale image files for laser adjustment of brightness is developed. The texture grayscale image files contain multiple different light adjustment layers. Each light adjustment layer is equipped with Noise, uniform noise, accurate color scale; download the texture grayscale image file to the laser engraving machine, combine the laser engraving process, reset the engraving parameters of the laser engraving machine, and apply different dimming layers to the existing main texture to change Cavity surface finish.

[0015] Wherein, the texture grayscale image file includes 100 light-adjusting layers that gradually change from white to black, wherein the brightness value corresponding to the first light-adjusting layer is 1%, and the brightness value corresponding to the second light-adjusting layer is 2%, and so on, the brightness value corresponding to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com