Steam crosslinking technology adopting steam crosslinking special tray

A technology of steam cross-linking and dishing, which is applied in the field of cable steam cross-linking process and steam cross-linking process, can solve the problems of large steam consumption, hidden dangers, unqualified cross-linking degree of inner layer insulation, etc. And the effect of low energy consumption, space saving and manufacturing cost, and guaranteed product cross-linking degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

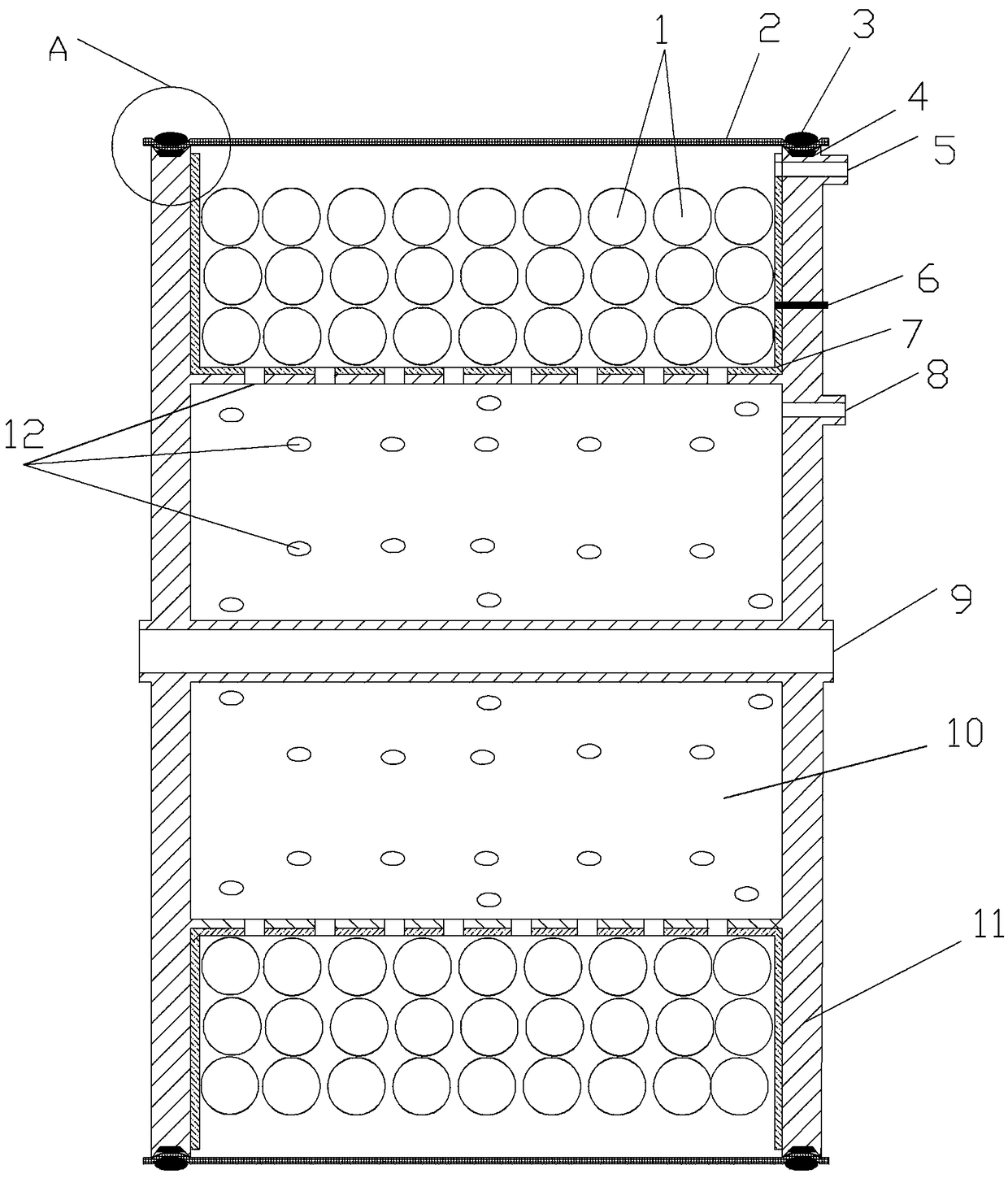

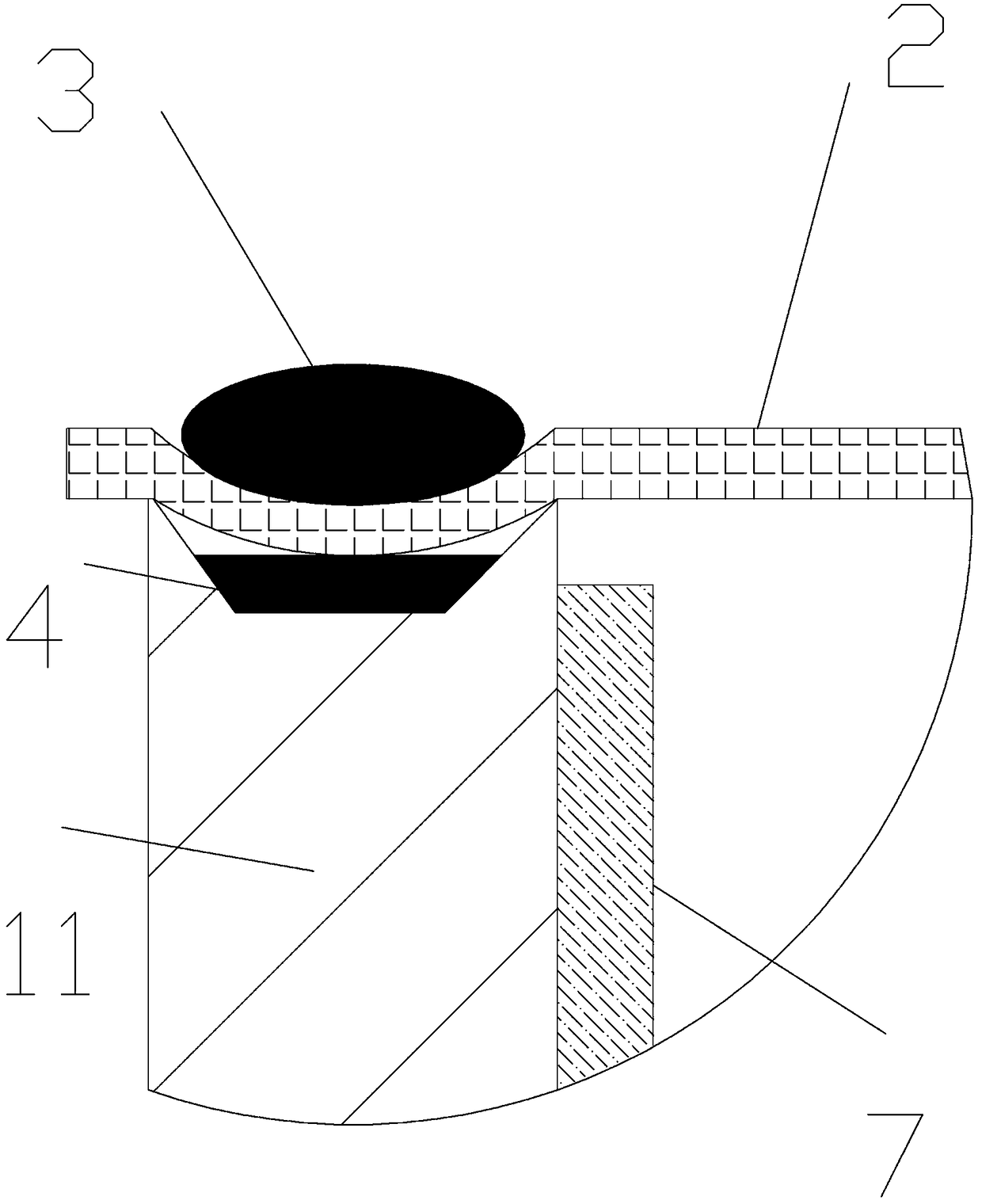

[0023] In order to make the solutions and advantages of the present invention more clear, the following will further describe the specific implementation manners of the present invention in detail with reference to the accompanying drawings.

[0024] The invention is a steam cross-linking process using a special plate for steam cross-linking. The extruded and insulated cables are wrapped on the thermal insulation rock wool board on the outer surface of the cylinder, and sealed by two disc-shaped side plates and the thermal insulation canvas layer. , the outer surface of the shaft tube and the inner surface of the cylindrical tube form an annular inner air-filled space, and an outer air-filled space is formed between the waterproof canvas layer and the cylindrical tube. The inner inflatable space and the outer inflatable space are connected through the air holes on the cylinder body, and the inner inflatable space and the outer inflatable space are inflated through the air inlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com