Silver oxide tungsten bronze composite heat-insulating material with high visible light photocatalytic performance and preparation method thereof

A thermal insulation material, tungsten bronze technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of low visible light utilization and visible light photocatalytic performance Improvement and other issues, to achieve the effect of visible light photocatalytic performance improvement, high practical application value, and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

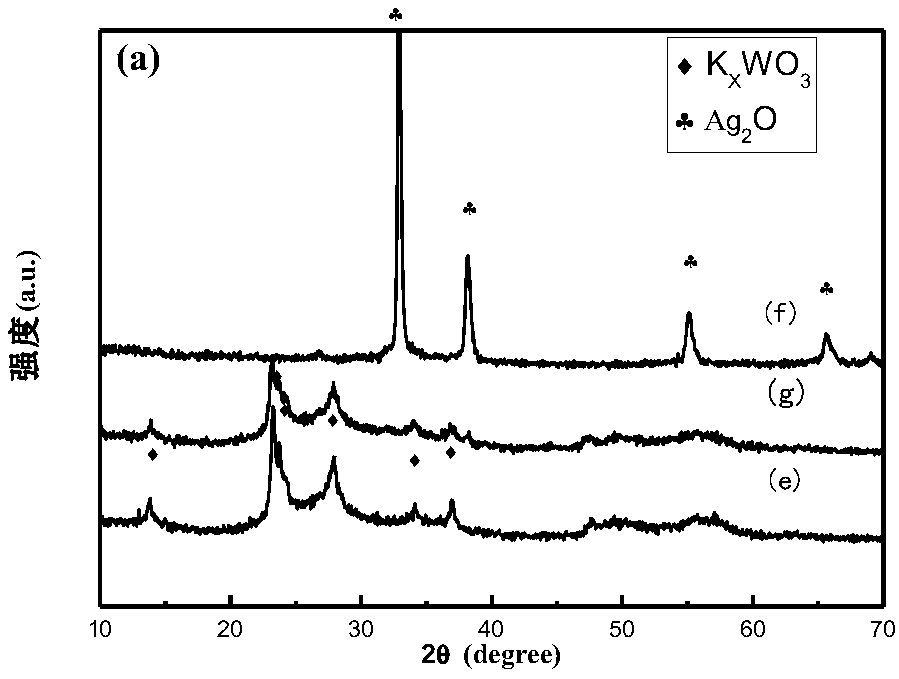

[0033] A method for synthesizing a silver oxide potassium tungsten bronze composite insulation material with high visible light photocatalytic performance, comprising the steps of:

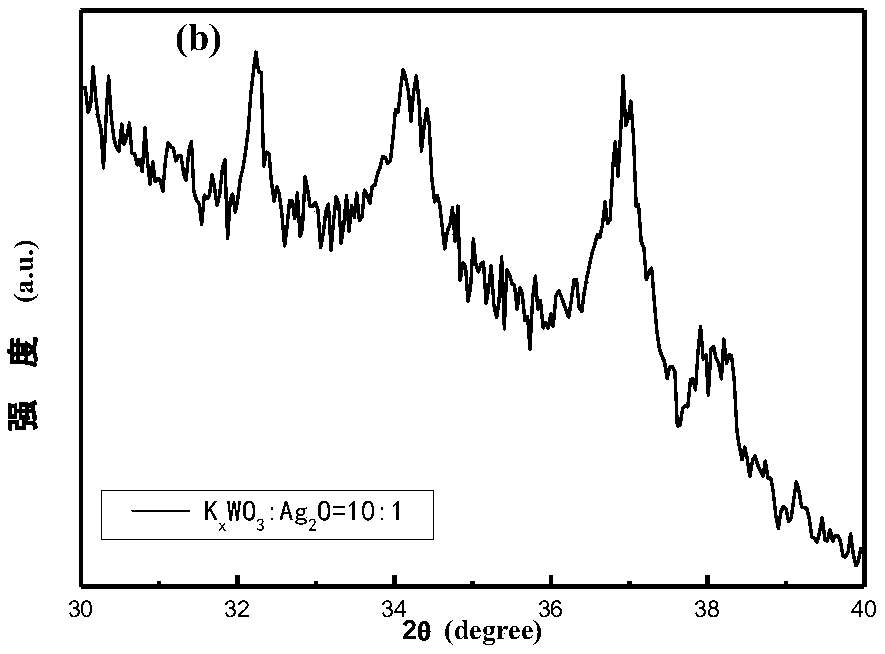

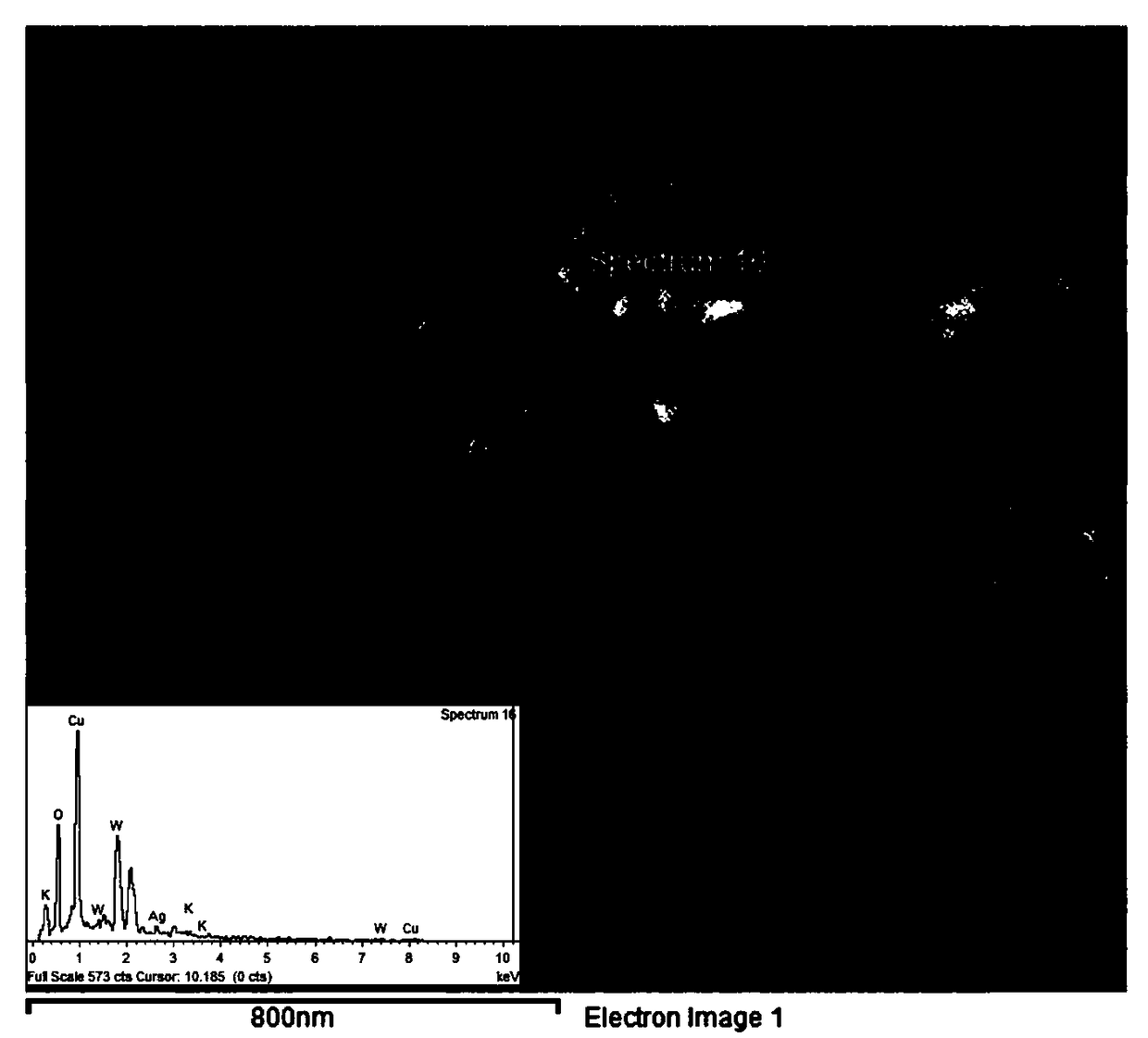

[0034] (1) Weigh 0.2g of potassium tungsten bronze and add it to a beaker with 50ml of deionized water, ultrasonically disperse it for 10 minutes to obtain dispersion A, weigh 0.029g of silver nitrate solid particles and place them in dispersion A, potassium tungsten bronze and oxidation The mass ratio of silver was 10 to 1; in the dark, after ultrasonic treatment for 10 min, and then magnetic stirring for 30 min in the dark, the dispersion B was obtained.

[0035] (2) Add dropwise enough to make all the silver ions in the solution into the sodium hydroxide solution of 0.01mol / L of silver oxide in the dispersion B, the pH value of control reaction is 8, while adding dropwise, magnetic stirring, After the dropwise addition, the magnetic stirring was continued for 5 min. Then, it was washed twice w...

Embodiment 2

[0037] A method for synthesizing a silver oxide potassium tungsten bronze composite insulation material with high visible light photocatalytic performance, comprising the steps of:

[0038] (1) Weigh 0.2g of potassium tungsten bronze and add it to a beaker containing 50ml of deionized water, ultrasonically disperse for 10 minutes to obtain dispersion A, weigh 0.0097g (the mass ratio of potassium tungsten bronze to silver oxide is 30 to 1) nitric acid The silver solid particles were placed in the dispersion A, and in the dark, ultrasonicated for 10 minutes, and then magnetically stirred for 30 minutes in the dark to obtain the dispersion B.

[0039](2) Add dropwise enough to make all the silver ions in the solution into the 0.01mol / L sodium hydroxide solution of silver oxide in the dispersion B, the pH value of the control reaction is 8, while adding dropwise, magnetically stirred, After the dropwise addition, the magnetic stirring was continued for 5 min. Then, it was washed ...

Embodiment 3

[0041] A method for synthesizing a silver oxide potassium tungsten bronze composite insulation material with high visible light photocatalytic performance, comprising the steps of:

[0042] (1) Weigh 0.2g of potassium tungsten bronze and add it to a beaker with 50ml of deionized water, ultrasonically disperse it for 10 minutes to obtain dispersion A, weigh 0.000733g (the mass ratio of potassium tungsten bronze to silver oxide is 200 to 1) nitric acid The silver solid particles were placed in the dispersion A, and after being ultrasonicated for 10 minutes in the dark, and then magnetically stirred for 30 minutes in the dark, the dispersion B was obtained.

[0043] (2) Add dropwise enough to make all the silver ions in the solution into the 0.01mol / L sodium hydroxide solution of silver oxide in the dispersion B, the pH value of the control reaction is 8, while adding dropwise, magnetically stirred, After the dropwise addition, the magnetic stirring was continued for 5 min. Then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com