Admixture for inhibiting bleeding of fabricated concrete and preparation method of admixture

An admixture and concrete technology, which is applied in the field of admixtures and its preparation for inhibiting prefabricated concrete bleeding, can solve the problems of affecting the appearance quality of concrete, large adverse effects, and weakening the surface appearance quality of concrete components, so as to ensure the appearance quality, High adaptability, the effect of avoiding delayed bleeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

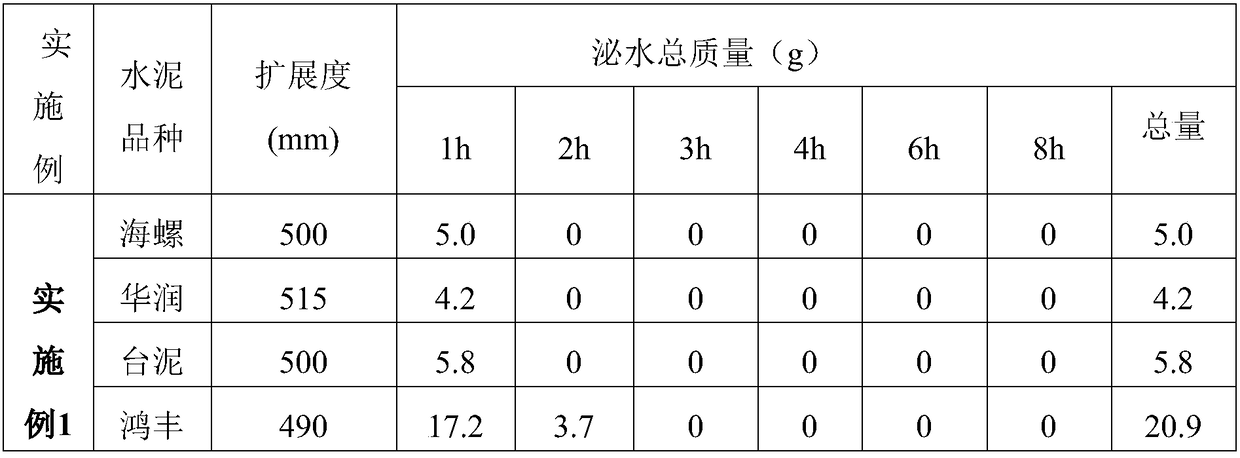

Embodiment 1

[0042] A kind of preparation method of polycarboxylate water reducing component comprises the steps:

[0043] 1) Dissolve 160 g of allyl polyoxyethylene ether with a molecular weight of 3500 in 100 g of water to form solution A;

[0044] 2) Dissolve 13g of acrylic acid and 3.3g of N-(3-dimethylaminopropyl)methacrylamide in 8g of water to prepare solution B;

[0045] 3) Dissolve 0.6g of mercaptopropionic acid and 0.3g of L-ascorbic acid in 45g of water to form solution C;

[0046] 4) Heat solution A to 50°C, add 0.45g of hydrogen peroxide to A, then add solutions B and C to A at the same time, the dropping time of solution B is 3.0h, and the dropping time of solution C 3.5h;

[0047] After all the addition is completed, continue to react for 1 hour, then reduce the temperature of the reaction solution to room temperature, adjust the pH value of the reaction solution to 6.0 with 20 g of sodium hydroxide solution (30 wt %), then add 109 g of water to obtain a mass concentration...

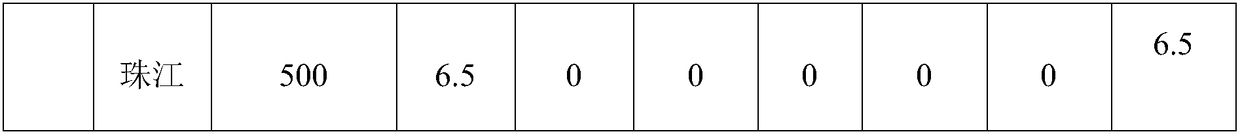

Embodiment 2

[0051] A kind of preparation method of polycarboxylate water reducing component comprises the steps:

[0052] 1) Dissolve 182 g of allyl polyoxyethylene ether with a molecular weight of 4000 in 120 g of water to form solution A;

[0053] 2) Dissolve 13g of acrylic acid and 3.3g of N-(3-dimethylaminopropyl)methacrylamide in 8g of water to prepare solution B;

[0054] 3) Dissolve 0.6g of mercaptopropionic acid and 0.3g of L-ascorbic acid in 45g of water to form solution C;

[0055] 4) Heat solution A to 50°C, add 0.45g of hydrogen peroxide to A, then add solutions B and C to A at the same time, the dropping time of solution B is 3.0h, and the dropping time of solution C 3.5h;

[0056] After all the addition is completed, continue to react for 1 hour, then reduce the temperature of the reaction solution to room temperature, adjust the pH value of the reaction solution to 6.0 with 20 g of sodium hydroxide solution (30 wt %), then add 122 g of water to obtain a mass concentration...

Embodiment 3

[0060] A kind of preparation method of polycarboxylate water reducing component comprises the steps:

[0061] 1) Dissolve 182 g of allyl polyoxyethylene ether with a molecular weight of 4000 in 120 g of water to form solution A;

[0062] 2) Dissolve 13g of acrylic acid and 5.0g of N-(3-dimethylaminopropyl)methacrylamide in 10g of water to form solution B;

[0063] 3) Dissolve 0.6g of mercaptopropionic acid and 0.3g of L-ascorbic acid in 45g of water to form solution C;

[0064] 4) Heat solution A to 50°C, add 0.45g of hydrogen peroxide to A, then add solutions B and C to A at the same time, the dropping time of solution B is 3.0h, and the dropping time of solution C 3.5h;

[0065] After all the addition is completed, continue to react for 1 hour, then reduce the temperature of the reaction solution to room temperature, adjust the pH value of the reaction solution to 6.0 with 20 g of sodium hydroxide solution (30 wt %), then add 122 g of water to obtain a mass concentration o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com