High-gloss light-transmission concrete, preparation method thereof and application

A light-transmitting concrete and high-gloss technology, applied in the field of decorative materials, can solve the problems of limited material application, lack of gloss on the surface of light-transmitting concrete, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The invention provides a preparation method of high-gloss light-transmitting concrete, comprising the following steps:

[0030] (1) mixing cement, aggregate, water reducing agent and water to obtain concrete slurry;

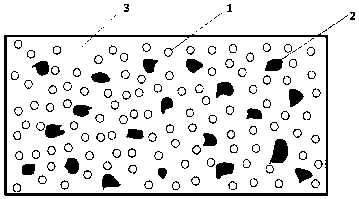

[0031] (2) disperse the translucent body in the concrete slurry obtained in the step (1) and then solidify to obtain a cured body;

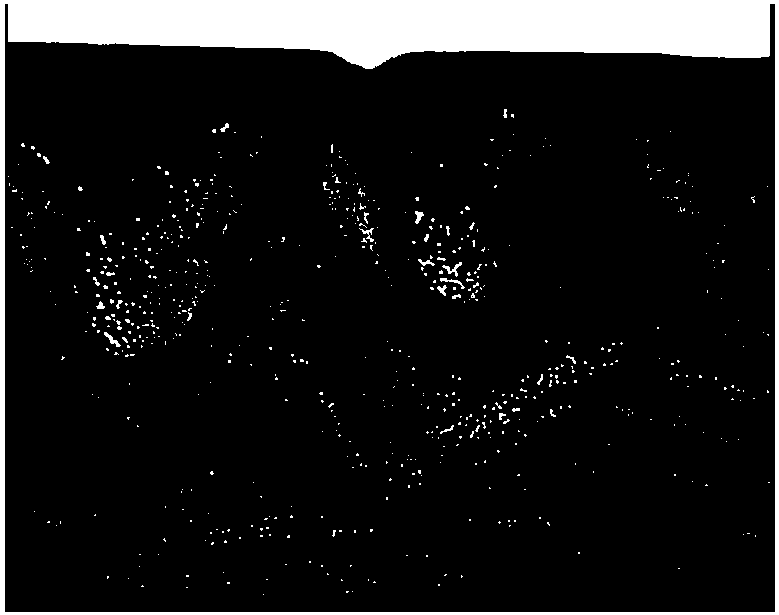

[0032] (3) The cured body obtained in the step (2) is subjected to rough grinding, fine grinding, reinforcement treatment and fine grinding in sequence to obtain high-gloss light-transmitting concrete; the particle size of the rough grinding film is 8- 20 mesh, the particle size of the diaphragm for fine grinding is 30 to 500 mesh, the particle size of the diaphragm for fine grinding is 1000 to 2000 mesh; the time of the coarse grinding, fine grinding and fine grinding is independently 1 to 100 min; the glossiness of the high-gloss light-transmitting concrete is 25-90 Gu.

[0033] The invention mixes cement, aggregate, wate...

Embodiment 1

[0059] Concrete slurry: in parts by mass, 1,000 parts of 42.5 ordinary Portland cement, 500 parts of 20-40 mesh sand, 500 parts of 40-80 mesh sand, 350 parts of stone with a particle size of 4mm, water-cement ratio 0.24, lignin 4.26 parts of sulfonate water reducer;

[0060] Strengthening slurry: 1 part of lithium polysilicon carbonate and 0.2 part of water;

[0061] The light-transmitting body is a light-guiding fiber with a diameter of 2mm and a length of 50mm.

[0062] Step (1) mixing the concrete slurry raw materials to obtain the concrete slurry;

[0063] Step (2) inject the concrete slurry into the mold, vertically insert the light-transmitting fiber into the concrete slurry, make the light-transmitting body contact the bottom of the mold, solidify at room temperature, demould after curing for 28 days, and obtain a solidified body;

[0064] Step (3) Roughly grind the solidified body with a diamond diaphragm with a particle size, and after the light-transmitting fiber i...

Embodiment 2

[0069] Concrete slurry: in parts by mass, 1,000 parts of 42.5 ordinary Portland cement, 550 parts of 30-mesh sand, 400 parts of 80-mesh sand, 300 parts of stone with a particle size of 10mm, water-cement ratio 0.30, melamine-based superplasticizer 3.7 copies;

[0070] Strengthening slurry: 1 part of lithium polysilicon carbonate and 1 part of water;

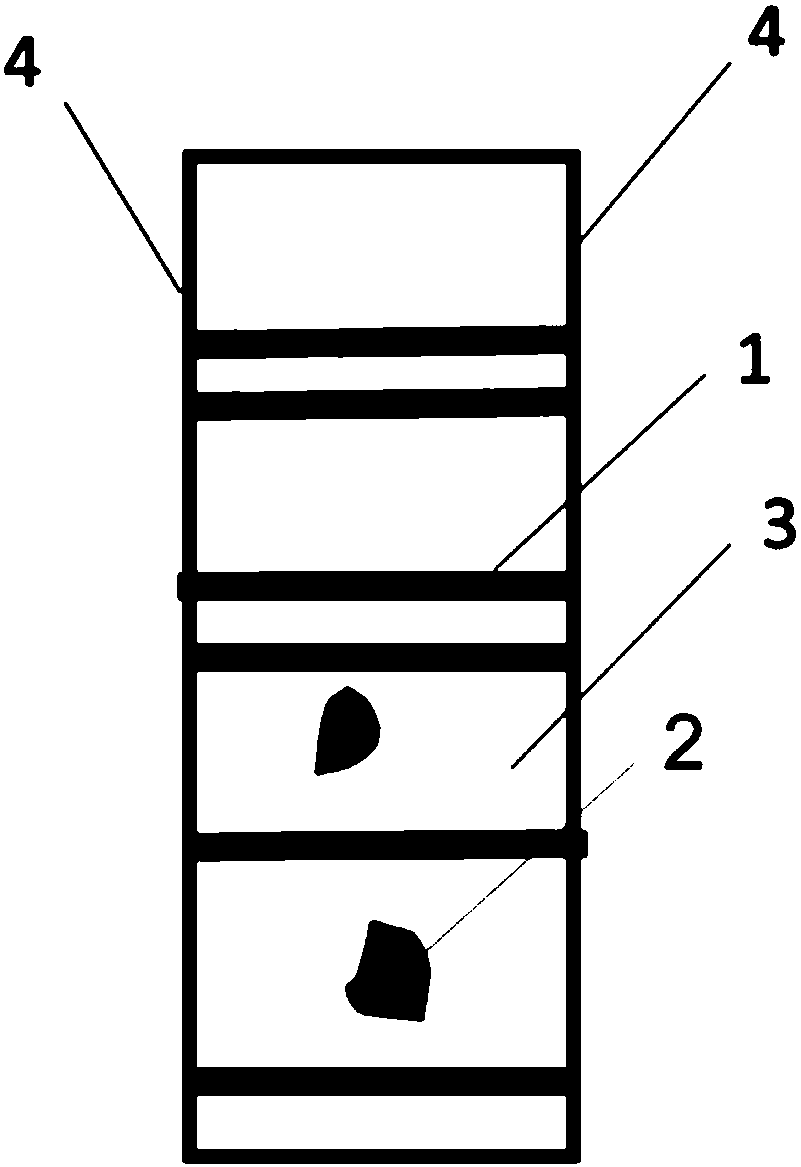

[0071] The light-transmitting body is an acrylic sheet with a size of 50×20×10mm.

[0072] Step (1) mixing the concrete slurry raw materials to obtain the concrete slurry;

[0073] Step (2) Fix the acrylic sheet in the mold with adhesive, control the distance between the acrylic sheet and the side wall of the mold to be 2cm, and the distance between the acrylic sheet and the acrylic sheet to be 2cm. After being cured for 15 days under the same conditions, the mold was released to obtain a cured body;

[0074] Step (3) Use a diamond diaphragm to roughly grind the solidified body. After the acrylic sheet is exposed to the concrete...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com