Water-soluble styrene-acrylic acid solid resin and preparation method thereof

A technology of solid resin and styrene, applied in the field of polyester, can solve the problems of incomplete monomer reaction of water-based acrylic emulsion, high storage and transportation costs, unstable product quality, etc., and achieve automatic continuous production, transportation safety, and production Process safe and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 and comparative example 1

[0028] The preparation method of embodiment 1 and comparative example 1 is specifically as follows:

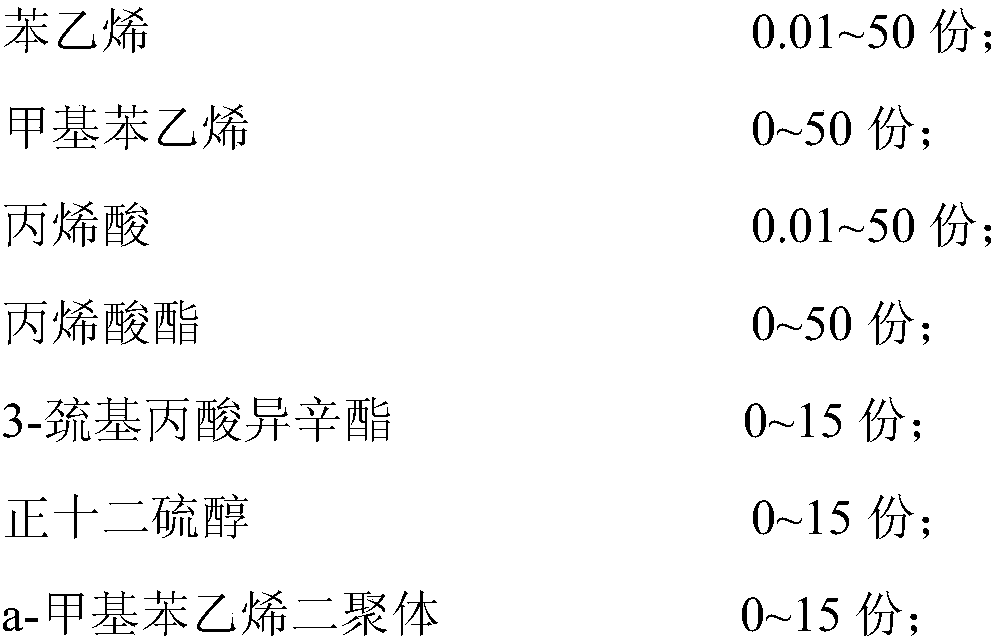

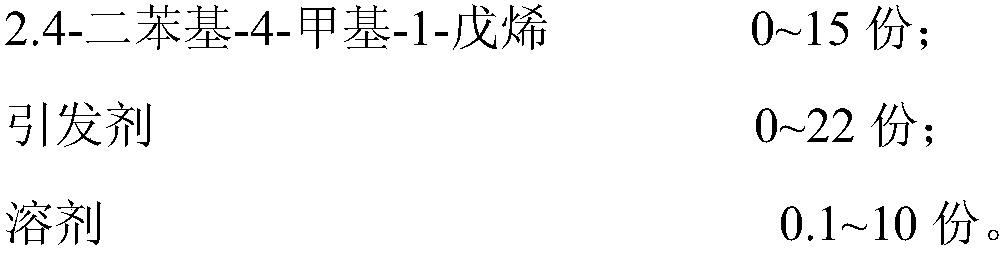

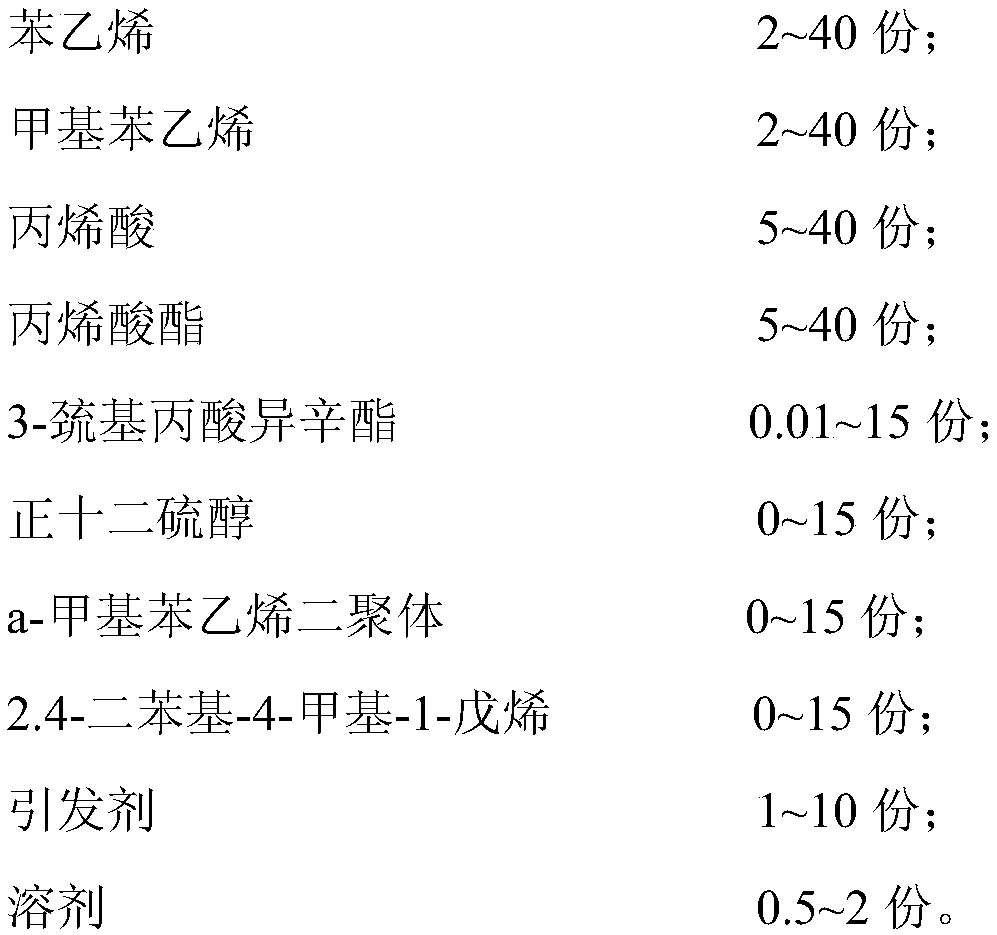

[0029] Styrene, methylstyrene, acrylic acid, acrylate, isooctyl 3-mercaptopropionate, n-dodecanethiol, a-methylstyrene dimer, 2.4-diphenyl-4-methyl- 1-pentene and an initiator are introduced into a tubular reactor, and polymerized in a solvent at a reaction temperature of 200-210° C. to obtain the target product.

Embodiment 2 and comparative example 2

[0030] The preparation method of embodiment 2 and comparative example 2 is as follows:

[0031] Styrene, methylstyrene, acrylic acid, acrylate, isooctyl 3-mercaptopropionate, n-dodecanethiol, a-methylstyrene dimer, 2.4-diphenyl-4-methyl- 1-pentene and an initiator are introduced into a tubular reactor, and polymerized in a solvent at a reaction temperature of 200-210° C. to obtain the target product.

Embodiment 3 and comparative example 3

[0032] The preparation method of embodiment 3 and comparative example 3, specifically as follows:

[0033] Styrene, methylstyrene, acrylic acid, acrylate, isooctyl 3-mercaptopropionate, n-dodecanethiol, a-methylstyrene dimer, 2.4-diphenyl-4-methyl- 1-pentene and an initiator are introduced into a tubular reactor, and polymerized in a solvent at a reaction temperature of 200-210° C. to obtain the target product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com