Heavy traffic road inspection well loop and construction method thereof

A construction method and inspection well technology, applied in artificial islands, waterway systems, water conservancy projects, etc., can solve problems such as land resource damage, small well circle weight, poor corrosion resistance, and poor sealing performance, so as to save construction time and improve construction efficiency , the effect of saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings of the specification, but the protection scope of the present invention is not limited to this:

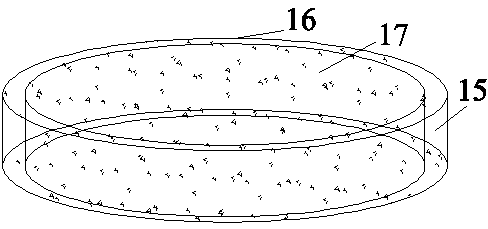

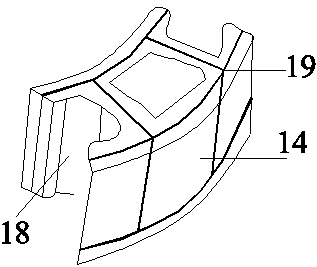

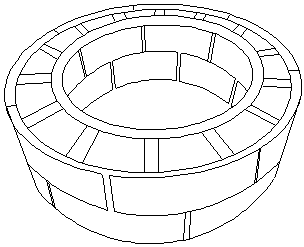

[0033] Such as Figure 1-6 As shown, the heavy-duty traffic road inspection well circle of the present invention includes inspection well bottom 1, inspection well middle 2, inspection well upper 3, well seat 9, ductile iron manhole cover 10, steel inner mold 37 and surrounding concrete simultaneous pouring well Seat installation system 34, the diameter of the bottom 1 of the inspection well is larger than the diameter of the middle part of the inspection well 2 and the upper part 3 of the inspection well; the well wall 5 is arranged between the bottom 1 of the inspection well and the steel inner mold 37, and the well wall 5 is provided with a pipe docking hole 13 The well base 9 is installed in the surrounding concrete synchronous pouring well base installation system 34, the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com