Battery cell of lithium battery

A technology for battery cells and lithium batteries, which is used in battery assembly, secondary battery manufacturing, non-aqueous electrolyte storage batteries, etc., can solve the problems of low processing efficiency, low welding quality, low auxiliary positioning accuracy, etc. Efficiency, welding quality and welding efficiency are high, and the effect is conducive to welding automation operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

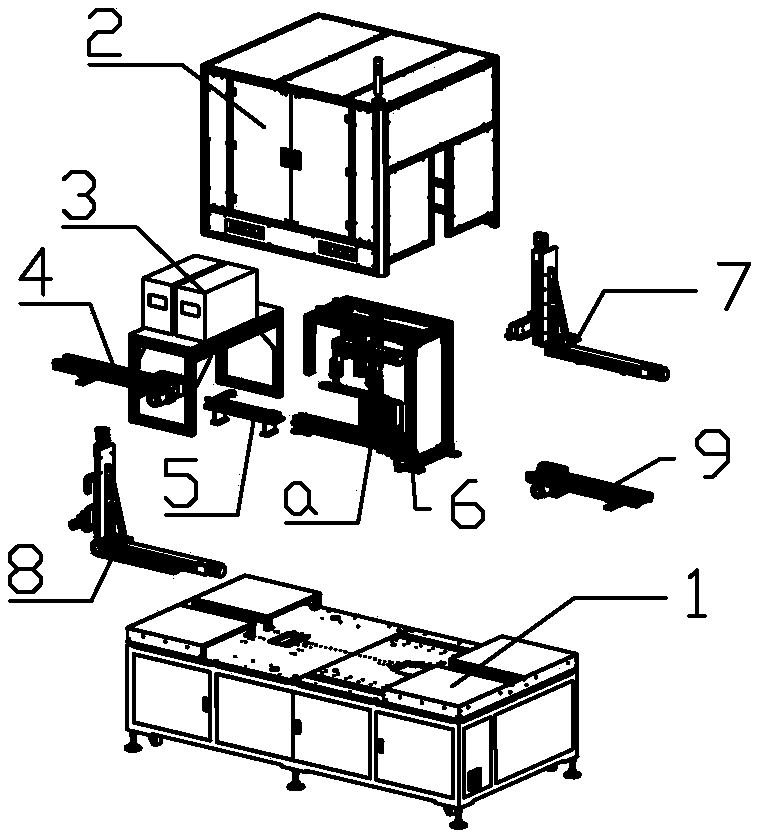

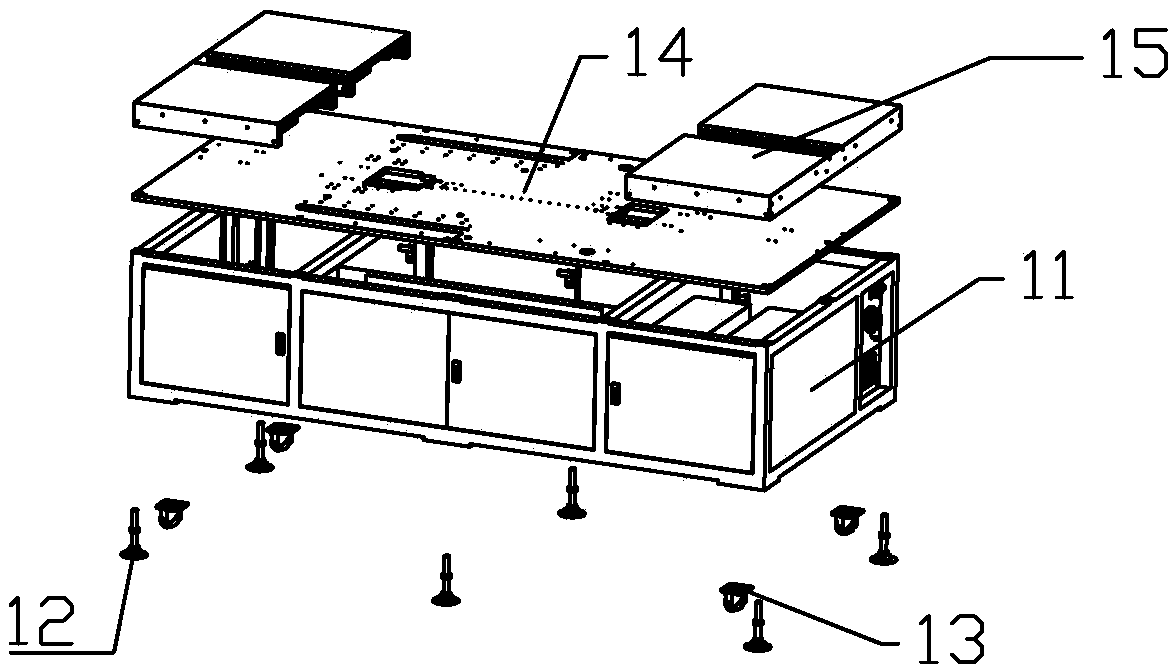

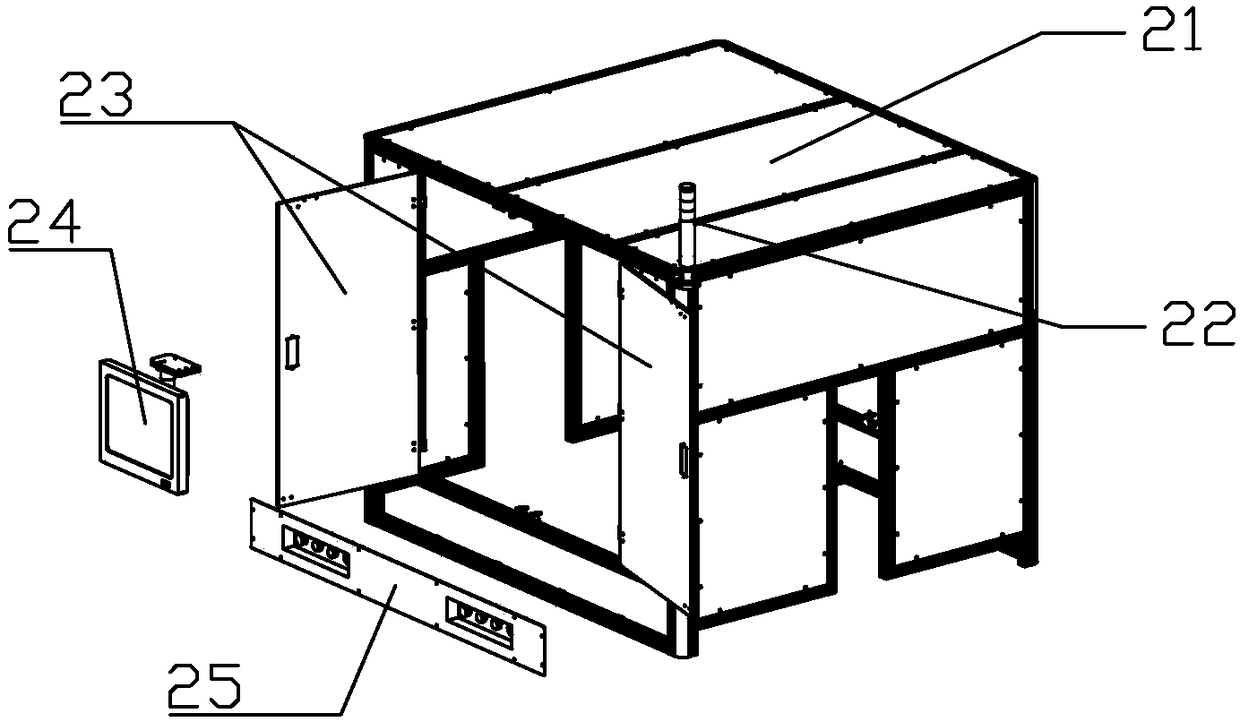

[0021] The present invention will be further described below with reference to the accompanying drawings and embodiments.

[0022] A lithium battery cell, the welding process comprises the following steps in sequence:

[0023] (1) Loading, put multiple battery cells into the cell fixture;

[0024] (2) Feeding, the cell fixture moves on the feeding belt until the position of the cell fixture is at the discharge end of the feeding belt, and the claw on the feeding device rotates clockwise until the front of the claw contacts the electric At the rear of the core fixture, the claw pushes the battery core fixture forward and enters the clamping device;

[0025] (3) Clamping, the lower clamping mechanism clamps the cell fixture in the axial direction of the clamping slide rail through the push block and the blocking block; the upper clamping mechanism presses the cell fixture on the clamping slide through the lower pressure plate. On the rail, clamp the cell fixture in the vertica...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap