Device and method for extracting 2-naphthol methyl ether from 2-naphthol, methyl alcohol, 2-naphthol methyl ether and p-toluenesulfonic acid and recovering components

A technology of p-toluenesulfonic acid and naphthalene methyl ether, which is applied in ether separation/purification, chemical instruments and methods, ether preparation, etc., can solve the problem of low yield in the refining process, achieve high purity and yield, simple process, highly operable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The present invention adopts above-mentioned device to extract 2-naphthyl methyl ether and reclaims the method for other components, comprises the steps:

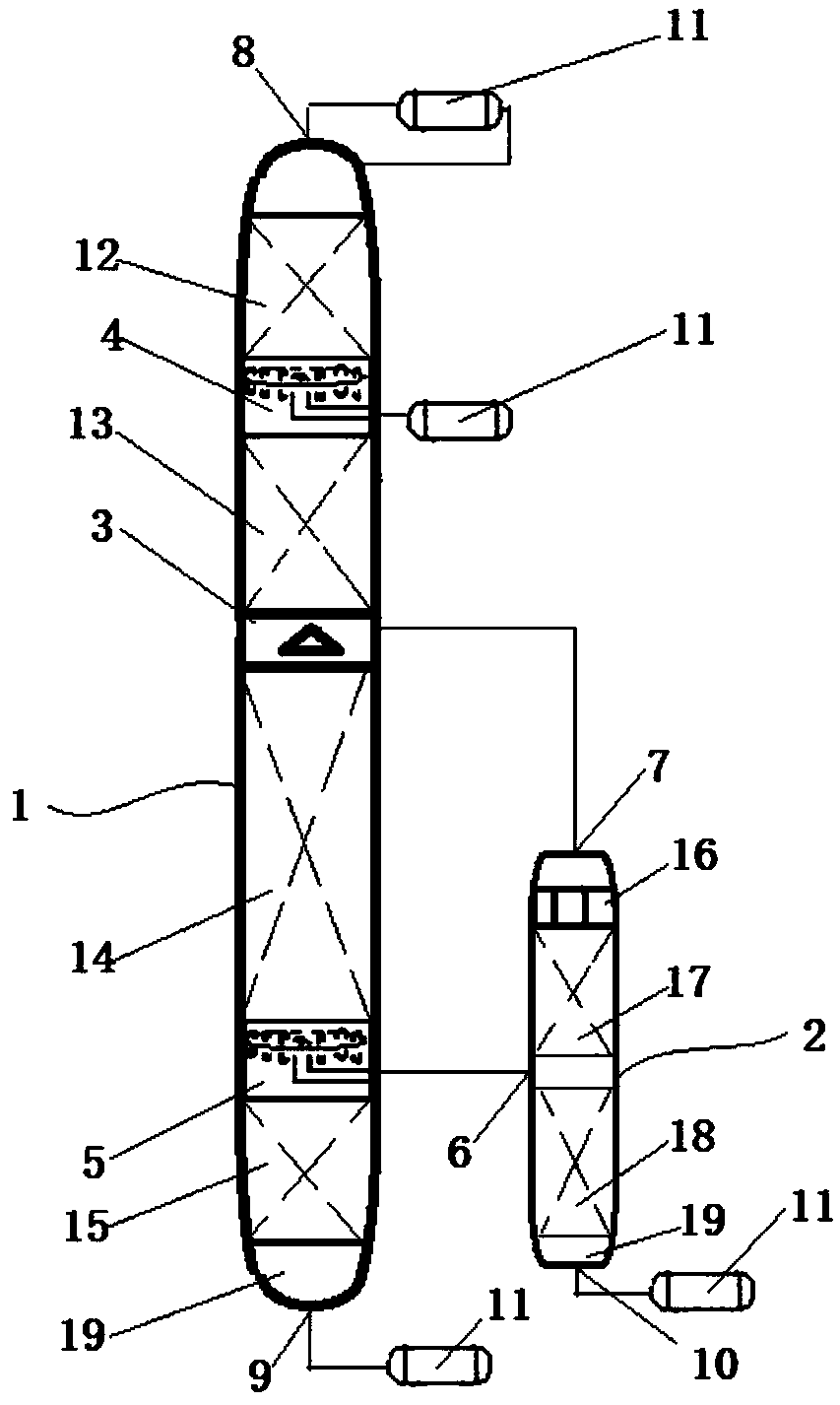

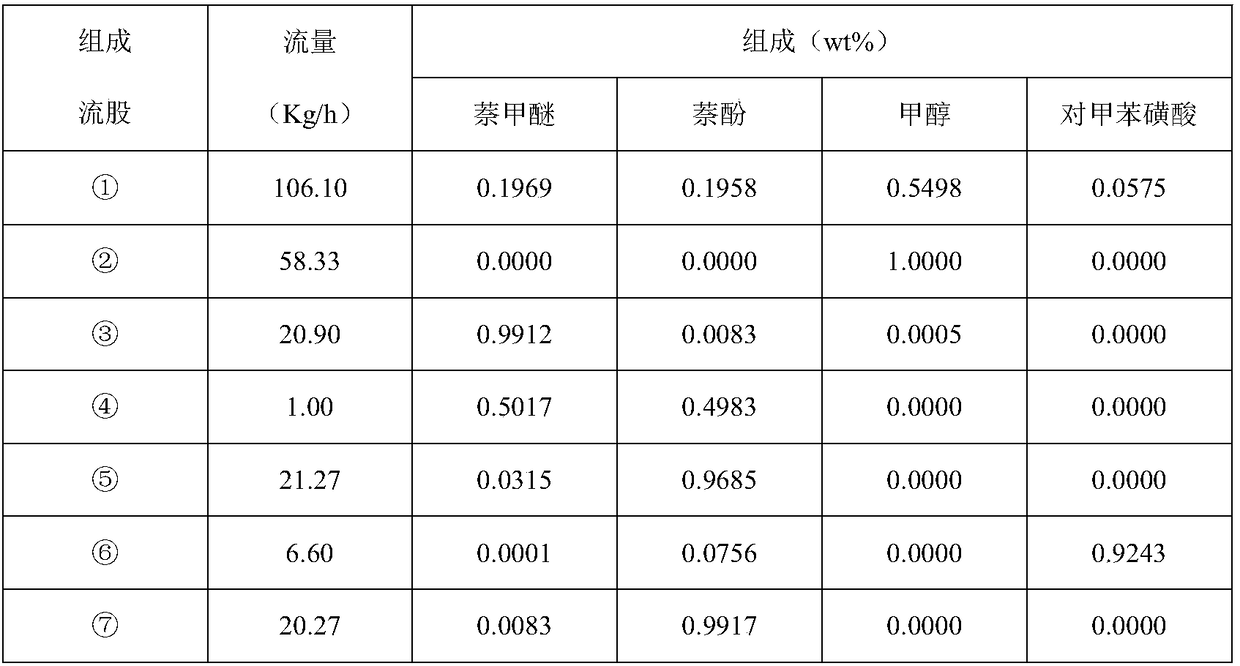

[0022] (1) adopt the continuous intermediate feeding mode, add the mixed solution (2-naphthol) of 2-naphthol, methyl alcohol, 2-naphthyl methyl ether and p-toluenesulfonic acid from the mixture inlet 3 of double side line rectifying tower 1 0.1958, methyl alcohol 0.5498, 2-naphthyl methyl ether 0.1969, p-toluenesulfonic acid 0.0575), through the condenser 11 and heater 19 at the top of the tower, the temperature at the top and bottom of the double-side line rectification tower 1 is controlled to be 28.3~30.2°C respectively and 256.7~259.1°C, set the reflux ratio of the condenser 11 at the top of the tower to 3:1, and adjust the pressure of the tower to 0.02MPa;

[0023] (2) When the top and bottom temperatures and the reflux ratio of the double-side line rectifying tower 1 were stable, the mixture feed port 3, methan...

Embodiment 2

[0029] The present invention adopts above-mentioned device to extract 2-naphthyl methyl ether and reclaims the method for other components, comprises the steps:

[0030] (1) adopt the continuous intermediate feeding mode, add the mixed solution (2-naphthol) of 2-naphthol, methyl alcohol, 2-naphthyl methyl ether and p-toluenesulfonic acid from the mixture inlet 3 of double side line rectifying tower 1 0.1958, methanol 0.5498, 2-naphthyl methyl ether 0.1969, p-toluenesulfonic acid 0.0575), through the condenser 11 and the heater 19 control the temperature of the top and bottom of the double-side line rectification tower to be 28.2~30.4°C and 256.5~260.2°C respectively , the reflux ratio of setting condenser 11 is 4:1, and the pressure of regulating tower is 0.02MPa;

[0031](2) When the top and bottom temperatures and the reflux ratio of the double-side line rectifying tower 1 were stable, the mixture feed port 3, methanol discharge port 8, 2-naphthyl methyl ether side line disc...

Embodiment 3

[0034] The present invention adopts above-mentioned device to extract 2-naphthyl methyl ether and reclaims the method for other components, comprises the steps:

[0035] (1) adopt the continuous intermediate feeding mode, add the mixed solution (2-naphthol) of 2-naphthol, methyl alcohol, 2-naphthyl methyl ether and p-toluenesulfonic acid from the mixture inlet 3 of double side line rectifying tower 1 0.1958, methanol 0.5498, 2-naphthyl methyl ether 0.1969, p-toluenesulfonic acid 0.0575), through the condenser 11 and the heater 19 control the temperature of the top and bottom of the double-side line rectification tower to be 28.3~30.2°C and 256.7~259.1°C respectively , the reflux ratio of setting condenser 11 is 4:1, and the pressure of regulating tower is 0.02MPa;

[0036] (2) When the top and bottom temperatures and the reflux ratio of the double-side line rectifying tower 1 were stable, the mixture feed port 3, methanol discharge port 8, 2-naphthyl methyl ether side line dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com