Device and method for preparing chlorine dioxide by using electrolysis method

A chlorine dioxide, electrolysis technology, applied in the electrolysis process, electrolysis components, cells and other directions, can solve the problems of complex process, high power consumption, low electrolysis efficiency, etc., to improve mass transfer rate, reduce energy consumption, increase The effect of large reaction rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

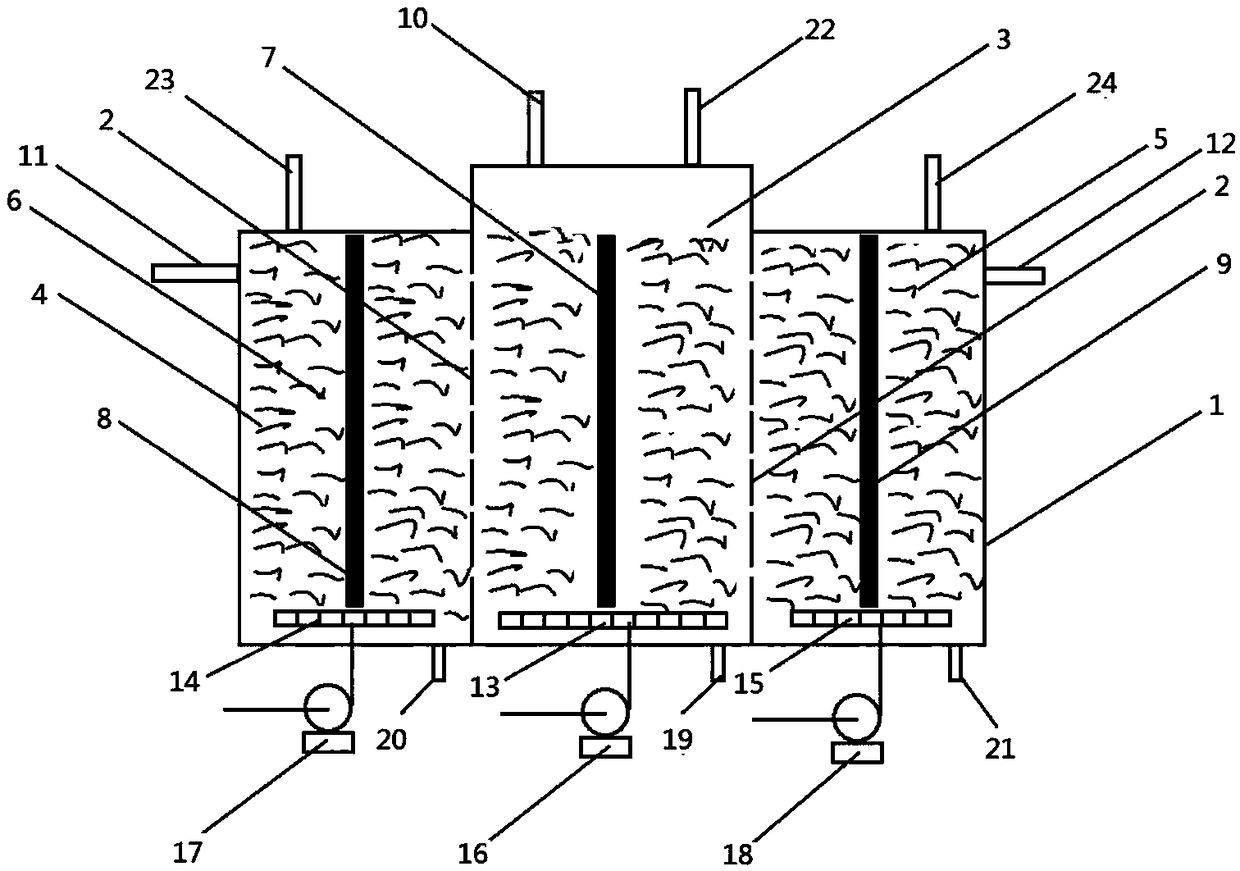

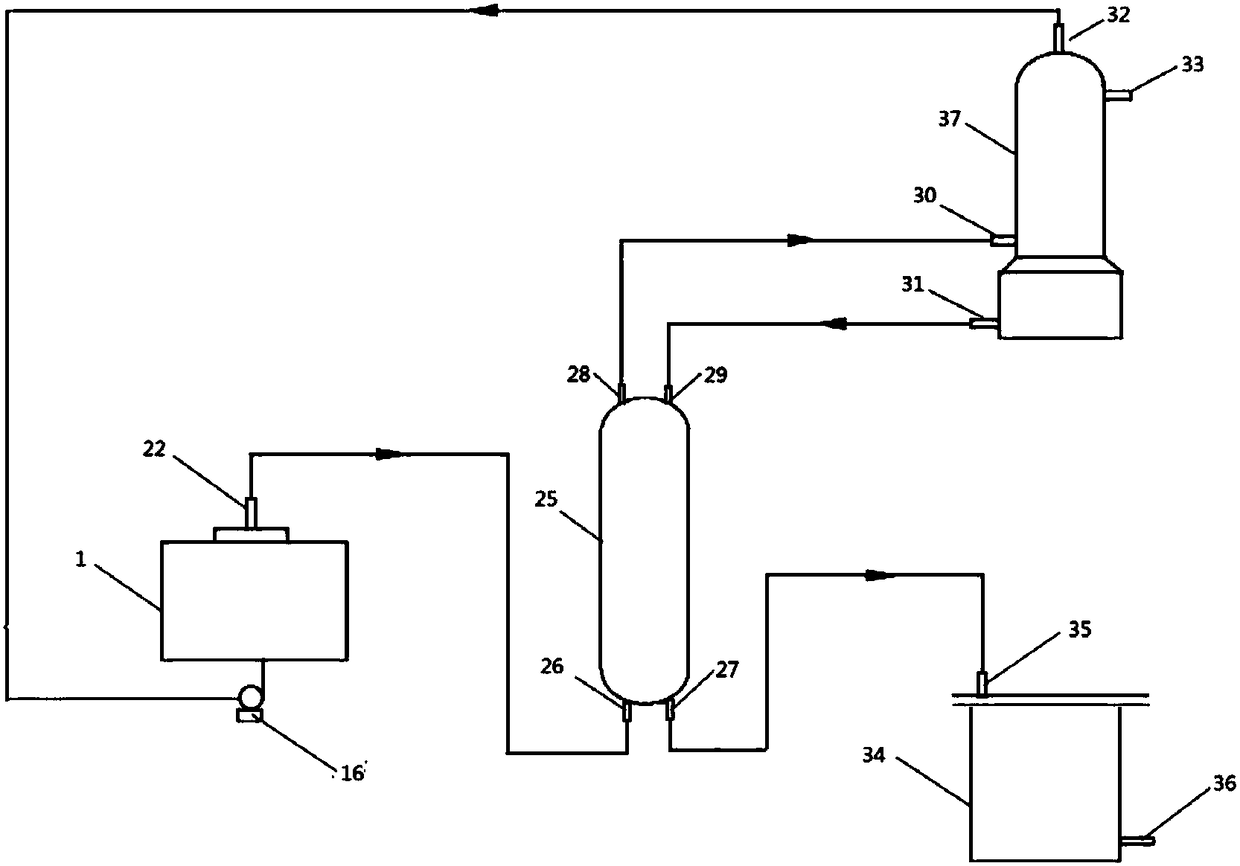

[0036] Attached below figure 1 And attached figure 2 The present invention will be further described.

[0037] Before starting the electrolysis, add sodium chlorite aqueous solution to the anode chamber 3, and add sodium sulfate solution to the first cathode chamber 4 and the second cathode chamber 5. The working voltage is DC 5-9V, and it is driven by commercial electricity or solar cells. .

[0038] The reaction principle of electrolytic sodium chlorite is as follows:

[0039] NaClO 2 +H 2 O→ClO 2 +NaOH+1 / 2H 2 (emitted from the cathode)

[0040] After the electrolysis occurs, the air is blown in by the air pump I16 through the gas distribution plate I13 in the anode chamber 3, and the ClO produced in the anode chamber 3 is dissipated. 2 The gas is blown into the absorption tower 25 . The unabsorbed chlorine dioxide gas discharged from the absorption tower 25 enters the tail gas absorption tower 37, and the residual chlorine dioxide gas is discharged from the tail g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com