Environment-friendly biomass fuel boiler

A biomass fuel and environmentally friendly technology, applied in the field of boilers, can solve problems such as poor respiratory environment and threats to life and health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

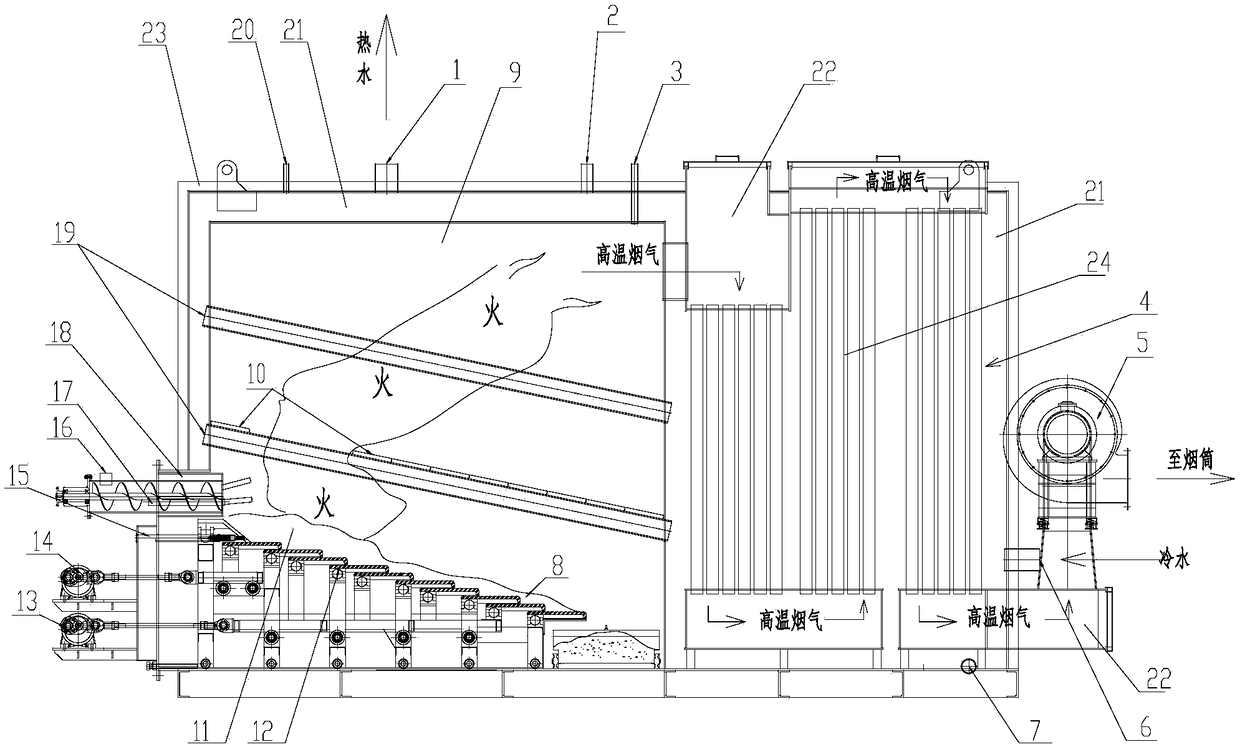

[0026] Such as figure 1 As shown, the environmentally friendly biomass fuel boiler of the present invention mainly includes: boiler hot water outlet 1, water replenishment and safety valve interface 2, heat exchanger inlet temperature sensing device 3, tube-and-tube three-pass heat exchanger 4, and smoke exhaust system 5. Cold water inlet 6, sewage outlet 7, ash 8, furnace hearth 9, furnace arch plate 10, fuel 11, heat-resistant cast iron reciprocating grate 12, secondary reciprocating drag system 13, primary reciprocating drag system 14, Automatic igniter 15, biomass particle feeding mechanism 16, temperature sensor device 17 in the high temperature zone of the furnace, secondary air system 18, diversion pipe 19, boiler hot water temperature sensor interface 20, water jacket 21, flue gas chamber 22, Body of heater 23 etc., concrete structure is as follows:

[0027]A furnace 9 and a tube-and-tube three-pass heat exchanger 4 are arranged in the furnace body 23. The upper side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com