Method for detecting chromium content in a chromium passivation waste liquid

A detection method and a technology of chromium content, which are applied in the field of chemical analysis, can solve the problems that the chromium content of chromium passivation waste liquid cannot be detected, and achieve the effect of simple operation and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

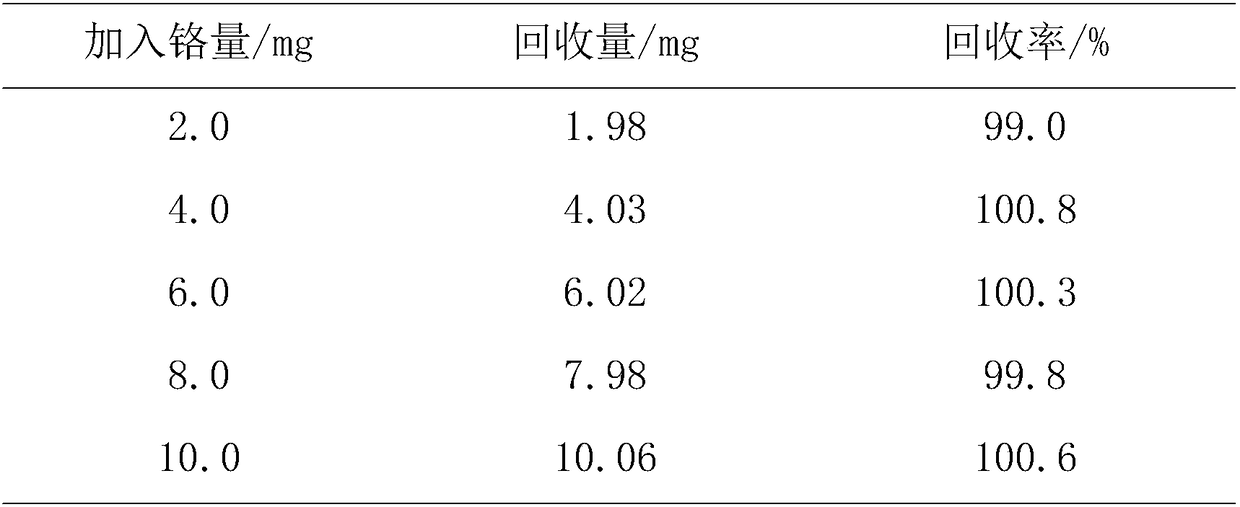

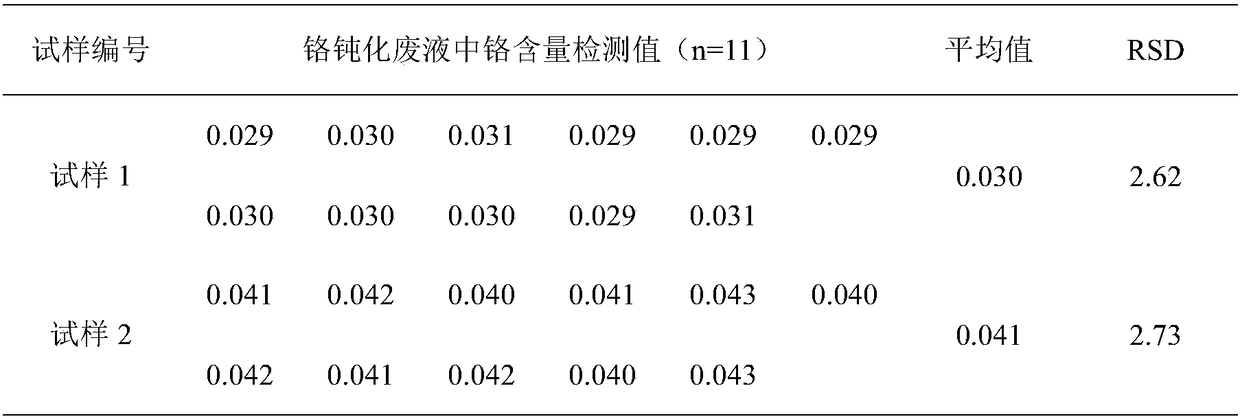

Examples

Embodiment Construction

[0014] A method for detecting chromium content in chromium passivation waste liquid, comprising the following steps:

[0015] 1) Prepare the solution to be tested, weigh 10.0053g of chromium passivation waste solution and place it in a platinum crucible, first remove the moisture and organic resin in the sample, specifically, first heat the sample from 20°C at a heating rate of 4°C / min Heat to 105°C and hold for 180 minutes; then heat the sample from 105°C to 250°C at a heating rate of 8°C / min and hold for 15 minutes; then heat the sample from 250°C to 500°C at a heating rate of 8°C / min and hold for 30 minutes ; Finally, heat the sample from 500°C to 815°C at a heating rate of 10°C / min, and keep it warm for 120min; then add 3g of a mixed reagent of sodium carbonate and boric acid with a mass ratio of 2:1 to the platinum crucible; then put the platinum crucible Place in a high-temperature furnace and melt at 1000°C for 15 minutes, take out the platinum crucible from the high-te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com