Glyphosate herbicide and preparation technology thereof

A technology of glyphosate herbicide and glyphosate, applied in the direction of herbicides, algicides, biocides, biocides, etc., can solve the problems of poor permeability, poor weeding effect of herbicides, etc., to reduce surface tension, Effect of reducing ineffective sublimation and improving absorption and utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1: a kind of glyphosate herbicide, it comprises the component of following parts by weight: glyphosate former medicine 32 parts, isopropylamine 8 parts, urea 0.5 part, soft water 30 parts, stearic acid ethylene glycol 6 parts of grease, 0.5 parts of alkylphenol polyoxyethylene ether, and 5 parts of polyacrylate. A kind of preparation technology of glyphosate herbicide, it comprises the following steps:

[0036] Step 1, mixing the original drug of glyphosate and isopropylamine in corresponding parts by weight evenly, stirring for 130min, the concentration of the original drug of glyphosate is 95%;

[0037] Step 2: Add corresponding parts by weight of urea and polyacrylate, stir in a constant temperature water bath for 30 minutes, the temperature of the water bath is 30°C, and the stirring speed is 30 rpm / min, and in the process of stirring, slowly add an appropriate amount of soft water, divide Add 5 times, maintain the temperature while stirring and let stan...

Embodiment 2-7

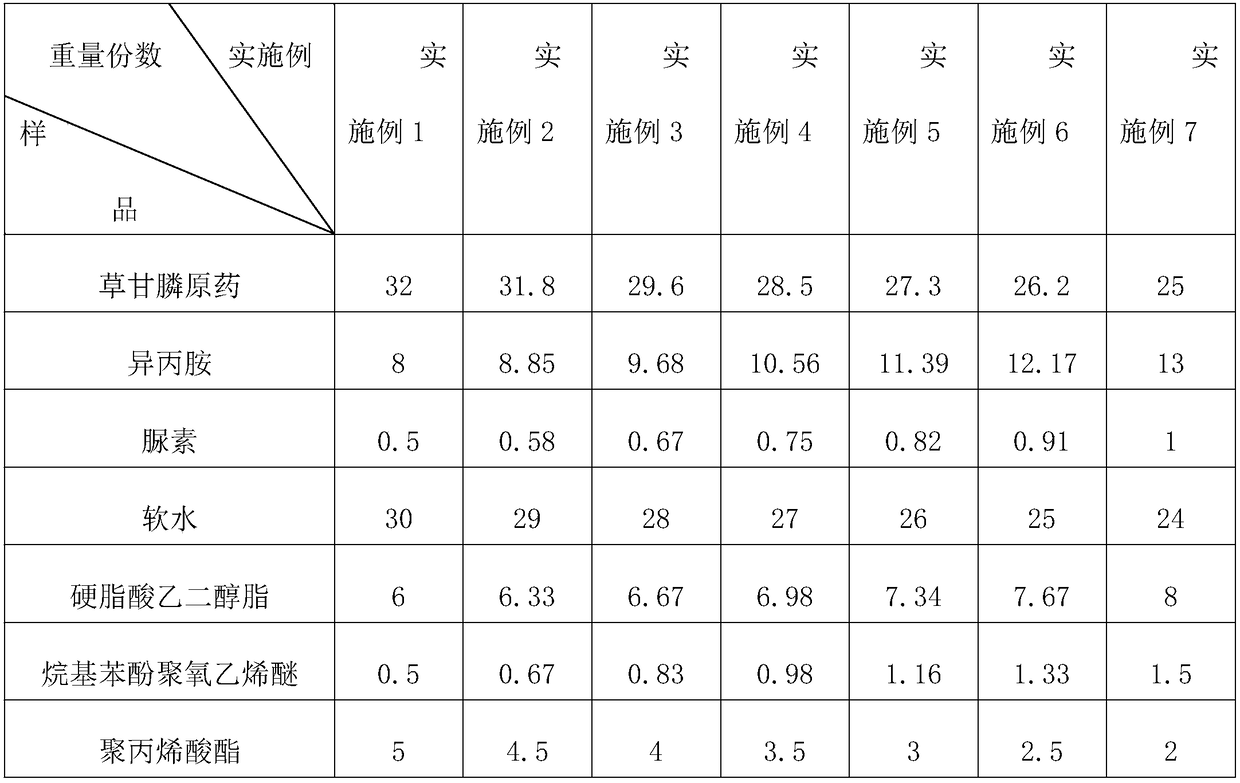

[0039] Example 2-7: A glyphosate herbicide, the difference from Example 1 is that each component and its corresponding parts by weight are shown in Table 1.

[0040] Each component and parts by weight thereof in table 1 embodiment 1-7

[0041]

Embodiment 8

[0042] Example 8: a glyphosate herbicide, the difference from Example 1 is that step a is also set between the step 1 and step 2: adding 0.5 parts by weight of 2,4-D Butyl ester was stirred in a constant temperature water bath for 20 min, the temperature of the water bath was 40°C, and the stirring speed was 40 rpm / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com