Production line and method for industrial producing edible mushrooms and protein feeds

A protein feed and production line technology, applied in feed, botanical equipment and methods, applications, etc., can solve problems such as low industry concentration, and achieve the effects of controlling product quality and safety, reducing costs, and saving land and labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

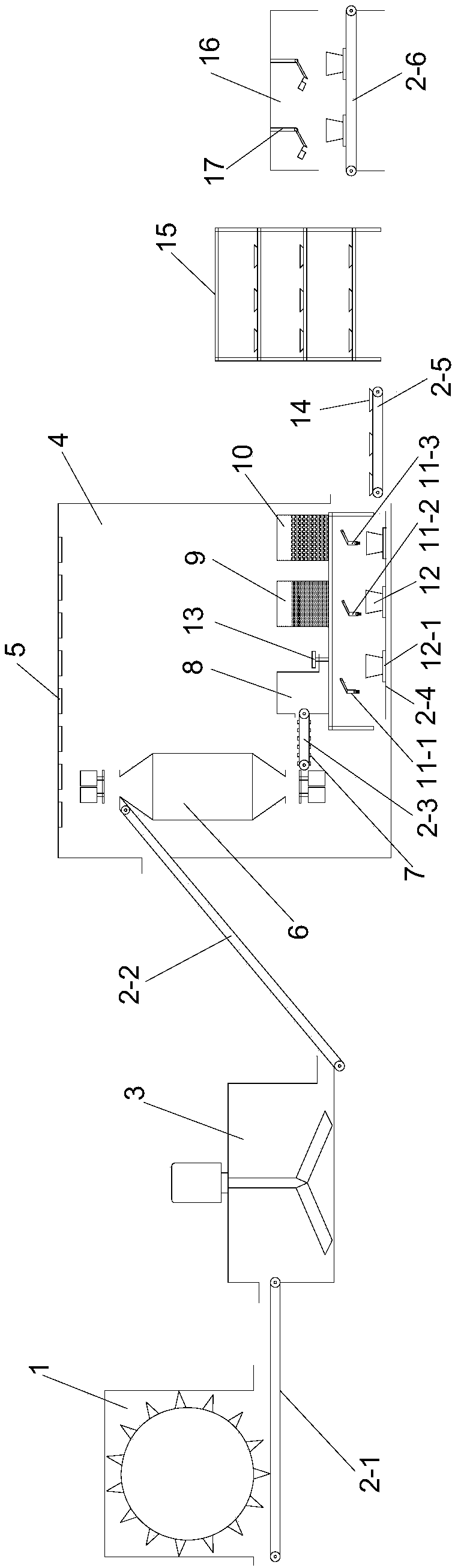

[0034] see figure 1 , a production line for industrialized production of edible fungi and protein feed, comprising a raw material crushing device 1, a mixing device 3, an ultra-clean inoculation production line 4, a fungus rack 15 and an automatic picking production line 16, a raw material crushing device 1, a mixing device 3, The ultra-clean inoculation production line 4, the bacteria rack 15 and the automatic picking production line 16 are sequentially connected by a conveyor belt; the ultra-clean inoculation production line 4 includes an extruding device 6, an ultrasonic microwave sterilization device 7, a charging device 8, an automatic inoculation device 9, and a coating device 10 Hefa bacteria cup 12, several ultraviolet lamps 5 are arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com