Honing magnetorheological polishing method and device

A magnetorheological polishing and honing technology, which is applied in grinding/polishing equipment, grinding automatic control devices, grinding machine tool parts, etc., can solve the problems of serious environmental pollution, lack of theoretical support, and low processing efficiency, and achieve High material removal rate, improved polishing efficiency, and guaranteed stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

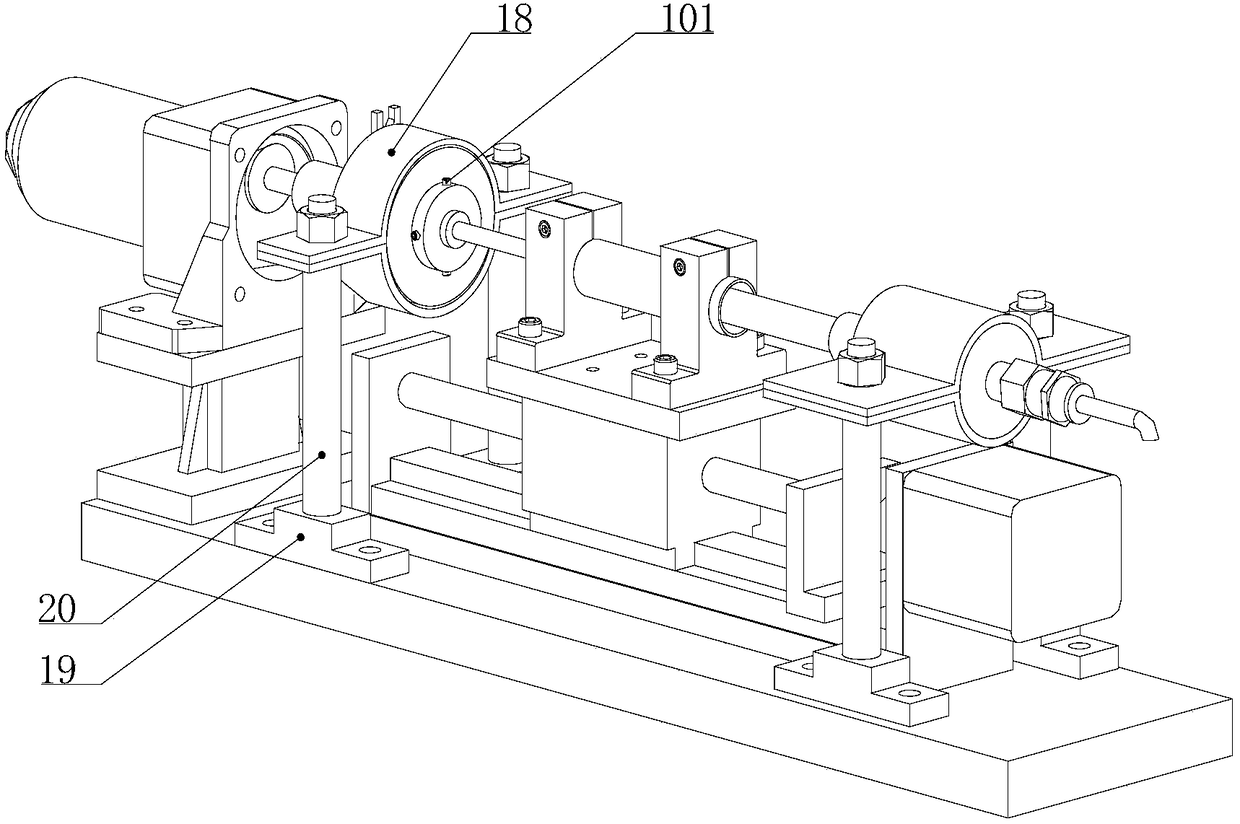

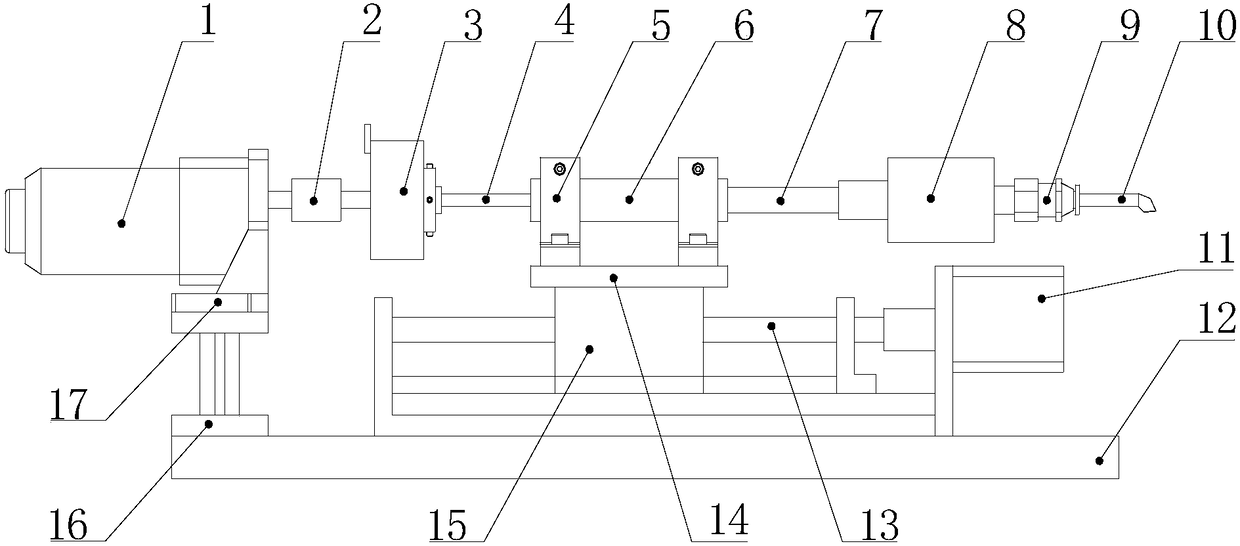

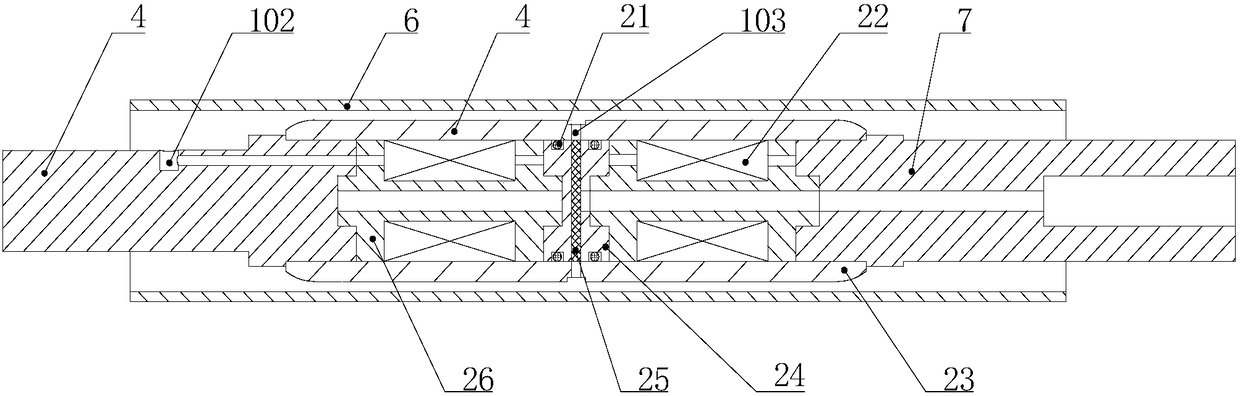

[0032] Such as Figure 1-Figure 3 As shown, the honing type magnetorheological polishing device of the present invention mainly includes: a speed regulating motor 1, a plum blossom coupling 2, a conductive slip ring 3, a transmission rod 4, a pipe fixture 5, a pipe fitting 6, a liquid delivery pipe 7, and a rotary joint 8. Hose connector 9, hose 10, stepper motor 11, frame 12, ball screw 13, connection plate 14, screw slider 15, motor pad 16, motor bracket 17, support frame 18, support seat 19. Column 20, O-ring 21, excitation coil 22, polishing head 23, end cap 24, magnetorheological polishing fluid 25, iron core 26, etc. The specific structure is as follows:

[0033]The speed-regulating motor 1 is fixed on the motor pad 16 through the motor bracket 17, the motor pad 16 is fixed on the frame 12 through ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com