Preparing method of porous graphene oxide

A graphene and graphene surface technology, applied in chemical instruments and methods, inorganic chemistry, carbon compounds, etc., can solve the problems that the etching process is difficult to control, the size and number of pores on the surface of porous graphene oxide cannot be controlled, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] refer to figure 1 , figure 1 It is a schematic flow diagram of the preparation method of the present invention. The method for preparing porous graphene oxide of the present invention mainly comprises the following steps: first prepare the composite of graphene oxide / magnetic transition metal oxide nanoparticles: graphene oxide (about 500nm in sheet diameter, figure 1 Substance A, prepared according to the method described in Ref: Nano Research 2015,8(4):1259-1268,) dispersed in ethanol and mixed with iron or cobalt or nickel salt solution, heated at 60-90°C 8 to 30 hours to grow seed crystals on the surface of graphene oxide to prepare a composite of graphene oxide / magnetic transition metal oxide nanoparticles, during which the magnetic transition metal ions form magnetic transition metal oxide nanoparticles. Then carry out seed growth and reduction on the composite of graphene oxide / magnetic transition metal oxide nanoparticles: transfer the above composite together...

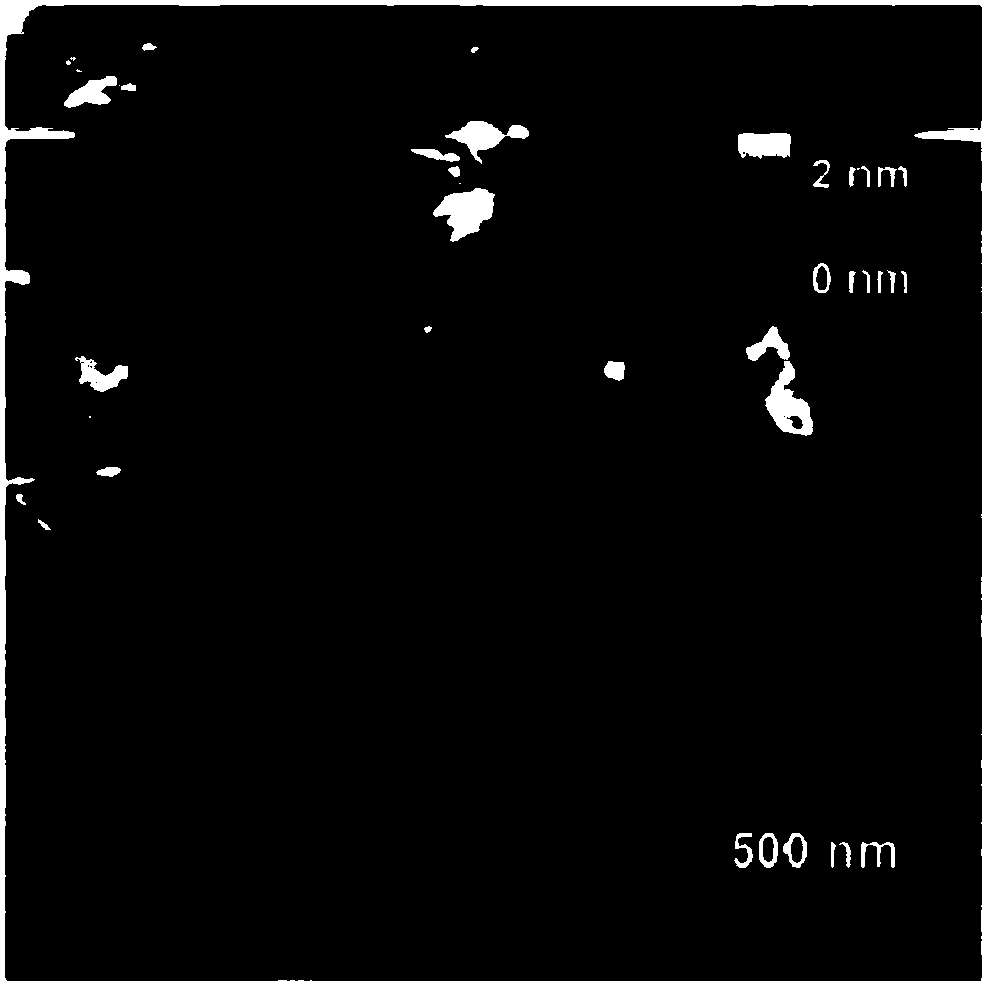

Embodiment 1

[0036] Porous graphene oxide with nanopores of 40-50 nm and 5-6 holes per graphene oxide sheet is prepared.

[0037] a. Preparation of graphene oxide / magnetic transition metal oxide nanoparticles composites.

[0038] 10mg of graphene oxide freeze-dried powder A1 (sheet diameter 500nm, prepared according to the method described in Ref: Nano Research 2015,8(4):1259-1268) was dispersed in 25ml of ethanol, and cobalt (II) acetylacetonate ( Co(acac) 2 ) ethanol solution (Co 2+ Concentration 0.2M, 1.2mL) mixed, heated at 80°C for 12h to grow seed crystals on the surface of graphene oxide to obtain a composite of graphene oxide / cobalt oxide nanoparticles.

[0039] b. Seed growth and reduction of the above complex.

[0040] The above complex was transferred together with the original solution into a 50ml autoclave, heated at 150°C for 3h, and the particles grew to 30-35nm. After cooling, it was centrifuged 3 times, washed 3 times with water, and washed 3 times with ethanol, and th...

Embodiment 2

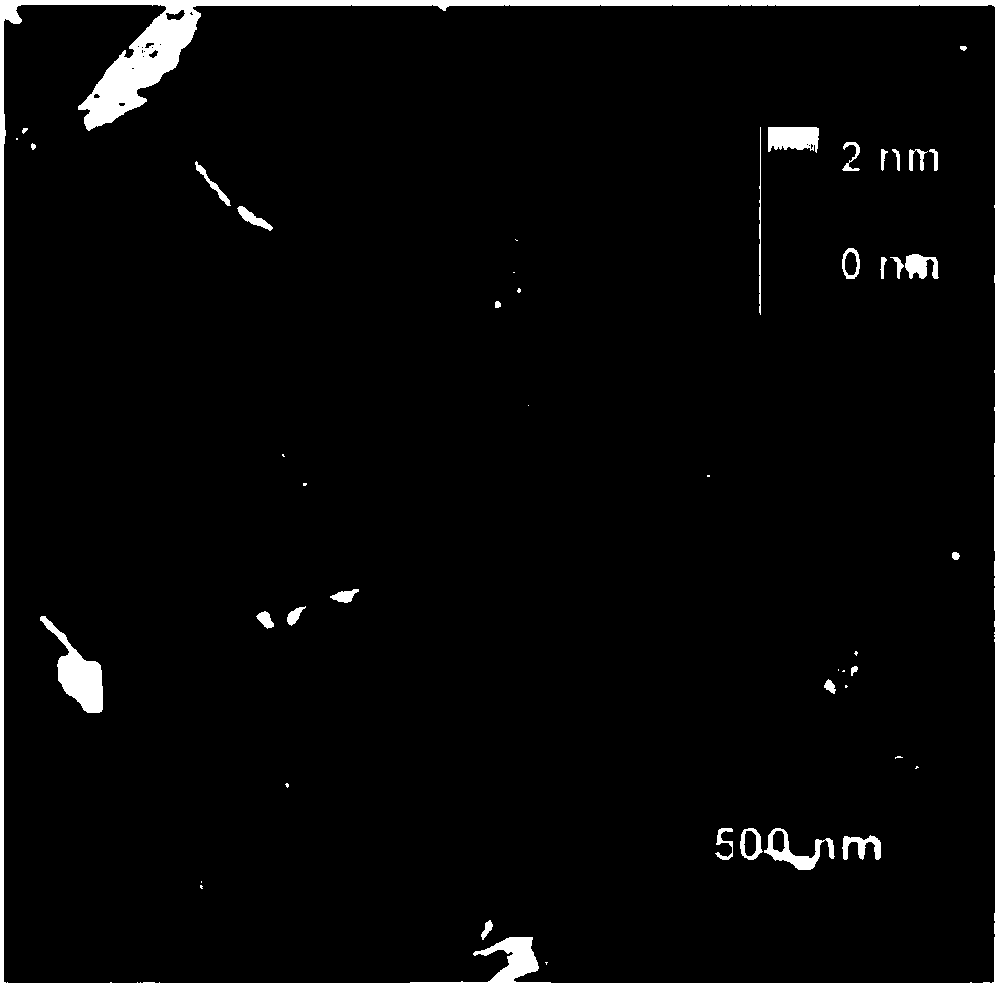

[0047] Porous graphene oxide with nanopores of 15-20 nm and 1-2 holes per graphene oxide sheet is prepared.

[0048] a. Preparation of composites of graphene oxide / magnetic transition metal oxide nanoparticles.

[0049] 10mg of graphene oxide freeze-dried powder A2 (sheet diameter 500nm, prepared according to the method described in Ref: Nano Research 2015,8(4):1259-1268) was dispersed in ethanol, and Fe(NO 3 ) 2 Aqueous solution (Fe 2+ Concentration 0.2M, 0.6mL) were mixed, and heated at 80°C for 12h to grow seed crystals on the surface of graphene oxide, thereby obtaining a composite of graphene oxide / iron oxide nanoparticles.

[0050] b. Seed growth and reduction of the above complex.

[0051] The above complex was transferred together with the original solution into a 50ml autoclave, heated at 150°C for 3h, and the particles grew to 10-15nm. After cooling, it was centrifuged 3 times, washed 3 times with water, and washed 3 times with ethanol, and then dried at room tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com