Post-treatment device for the cleaning of automobile parts

A technology for post-treatment devices and auto parts, applied in special treatment targets, water/sewage treatment, water/sewage treatment equipment, etc., can solve the problem of not being able to automatically add flocculants, flocculants and sewage, and achieve simple structure and tightness. Good, avoid the effect of tight fit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

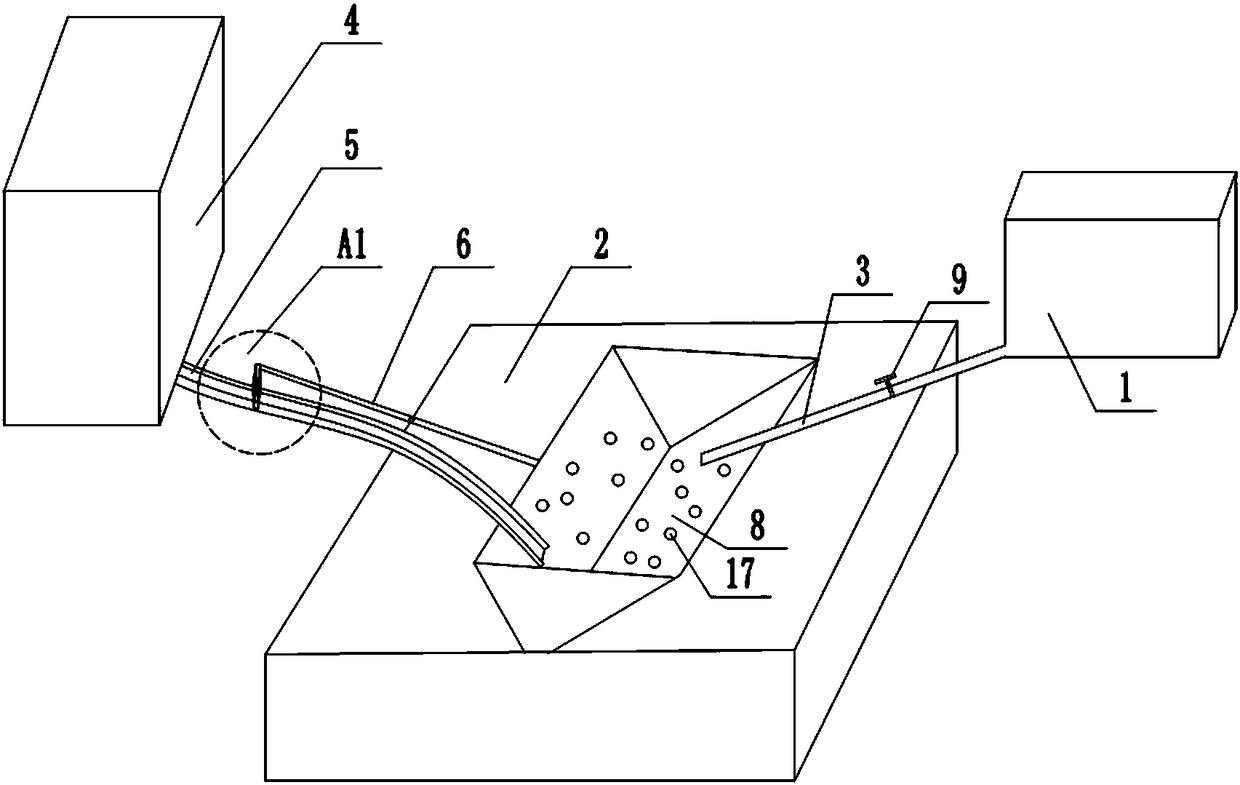

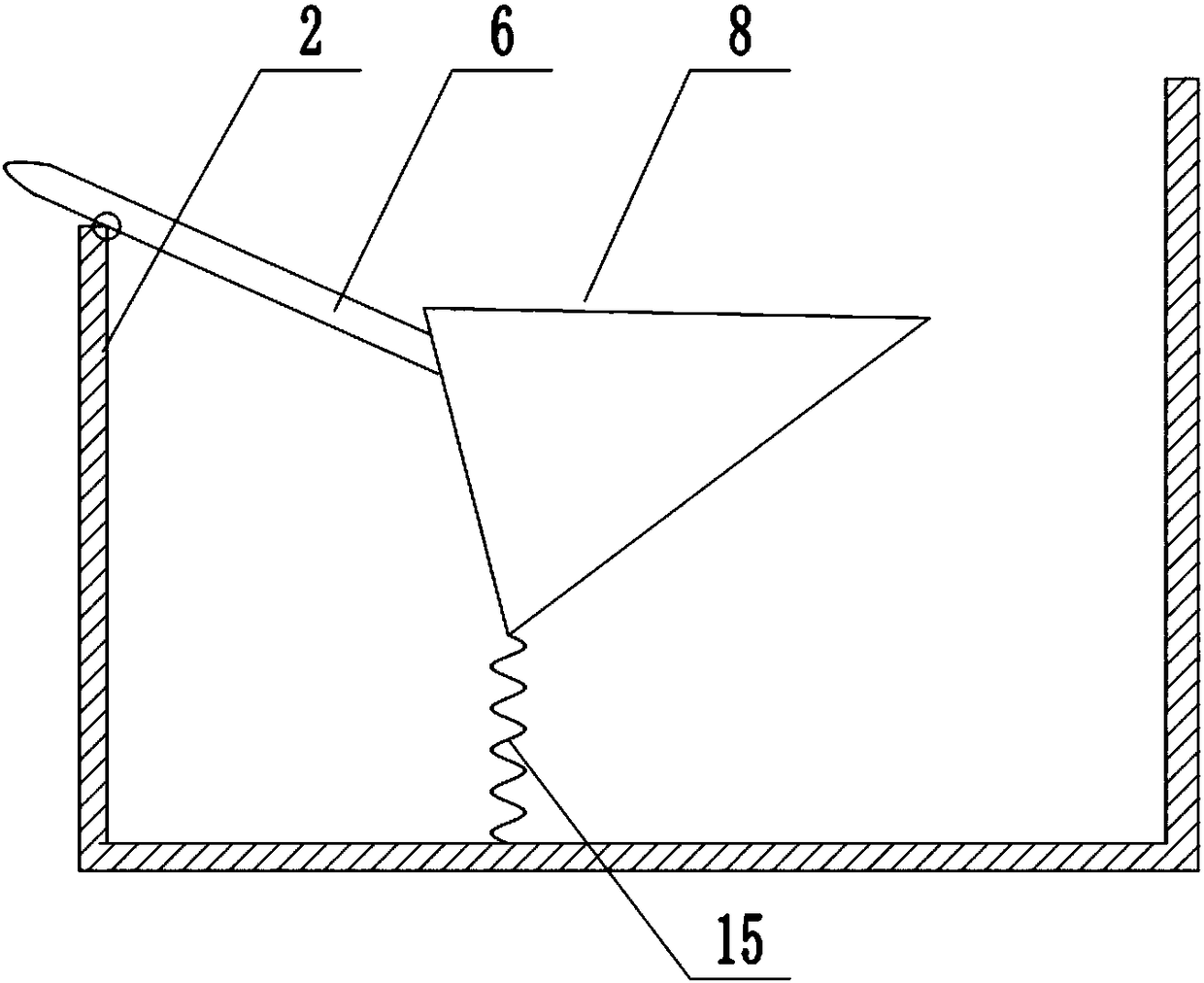

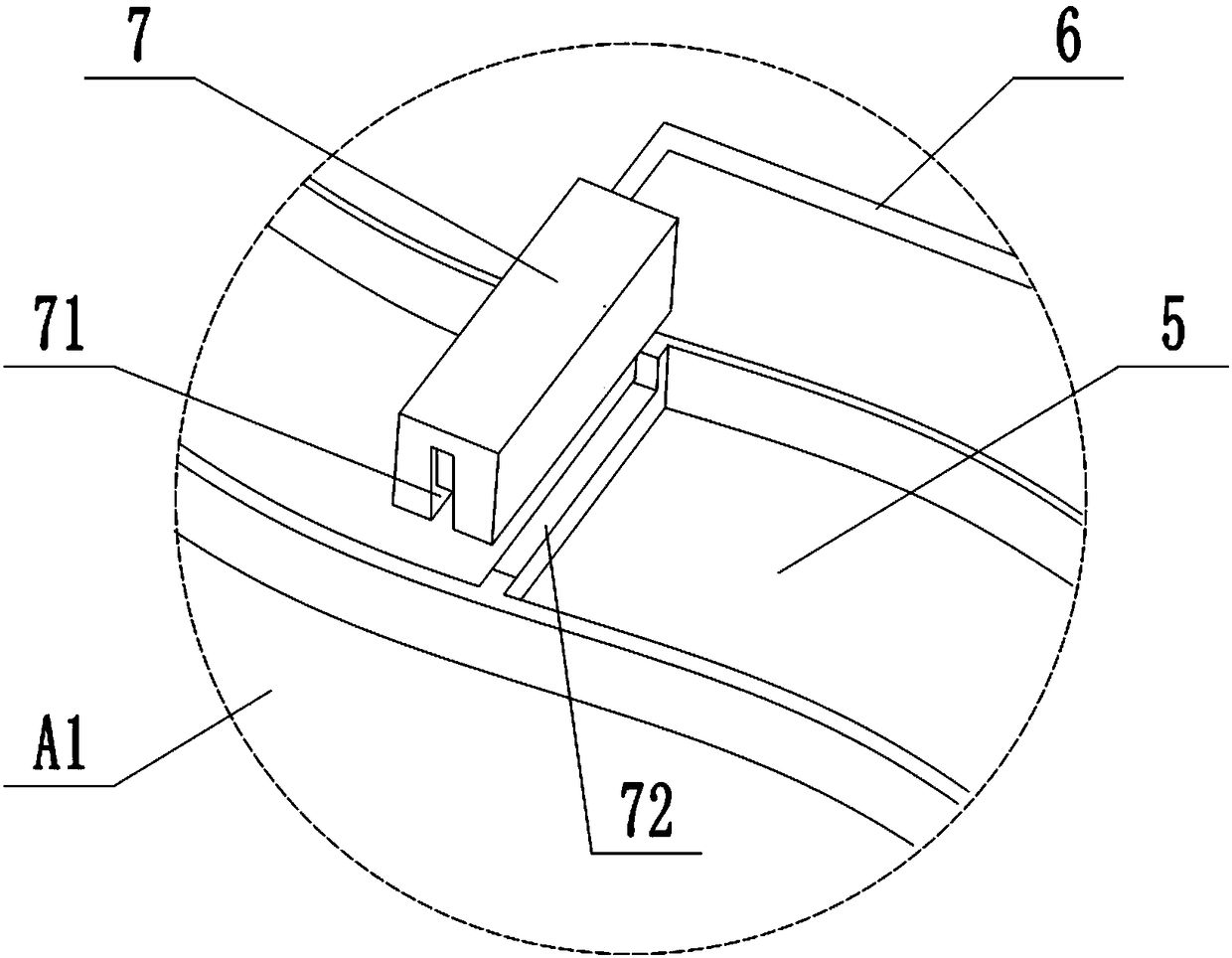

[0027] Such as figure 1 , image 3 As shown, the auto parts cleaning post-processing device includes a sewage conveying mechanism 1 and a sedimentation tank 2, and also includes a flocculant supply mechanism. The flocculant supply mechanism includes a storage part 4, a reaction pool 8, and a channel for guiding the flocculant into the reaction pool 8 5. There is a gate 7 on the channel 5, and a long shaft 6 is hinged on the wall of the sedimentation tank 2. The right end of the long shaft 6 is fixedly connected with the reaction tank, and the left end of the long shaft 6 is fixedly connected with the switch of the gate 7. There are several Tapered rubber holes. Such as figure 2 As shown, there is a compression spring 15 between the bottom of the reaction tank 8 and the sedimentation tank 2 , and the water outlet of the sewage conveying mechanism 1 is above the reaction tank 8 . Among them, such as image 3 , Figure 4 As shown, the channel 5 that guides the flocculant to...

Embodiment 2

[0032] Such as Figure 5 As shown, the difference between the auto parts cleaning post-processing device and the first embodiment is that the water valve 9 is a gate valve, which includes a fixedly connected gate 10 and a handle 13. Because the gate 10 and the handle 13 are fixedly connected, the handle The movement of 13 can drive the gate 10 to move so as to achieve the purpose of controlling whether the water flow passes; there is a spring between the gate 10 and the water pipe 3, so after the handle 13 loses the pressing force of the semi-disc 11, the gate 10 is supported by the spring 14 The force falls to keep the water valve closed. Wherein the incomplete rotating disc is a half disc, and the axis center of the half disc rotation is below the handle. When the half disc 11 rotates around the rotating shaft 12, half of the time squeezes the handle 13 and half of the time leaves the handle 13, thereby achieving control. The purpose of intermittent switch of flashboard 10....

Embodiment 3

[0035] Such as Figure 6 As shown, the difference between the auto parts cleaning post-processing device and the second embodiment is that the incomplete turntable is a cam 16 . The smoother curve of the cam 16 will make the process of changing the force on the handle 13 a gradual process, so the water valve 9 that uses the structure of the cam 16 to control the opening and closing is less noisy, and the wear of the handle 13 is smaller, so the use of the water valve 9 Longer life.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com