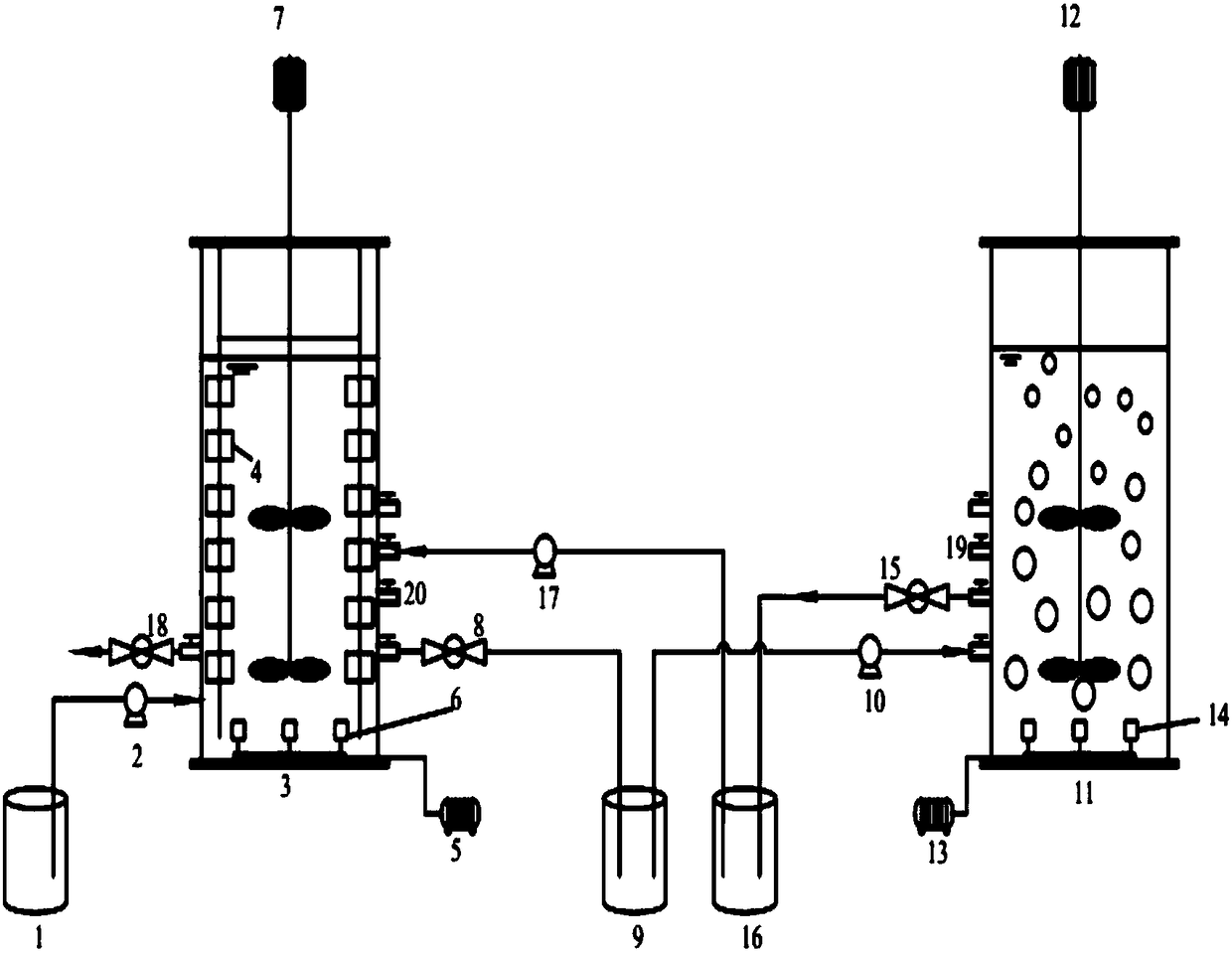

Device and method for improving A2NSBR two-sludge denitrification denitriding and phosphorus removal process on basis of DEAMOX technology

A nitrification denitrification and double sludge technology, which is applied in chemical instruments and methods, biological treatment devices, water/sludge/sewage treatment, etc., can solve the problem of high concentration of ammonia nitrogen in the effluent, achieve interception and solve the problem of high concentration of ammonia nitrogen , Improve the effect of processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0022] 1) Domestic sewage enters the A / A / O-SBR reactor (3) from the raw water tank (1) through the first water inlet pump (2), and the first agitator (7) starts stirring. DPAOs denitrifying phosphorus-accumulating bacteria use volatile fatty acids in raw water to synthesize internal carbon sources, and at the same time DPAOs release phosphate in the body to the outside, and most of the COD in the influent water is removed during this process; this stage controls A / A / O- DO≤0.02mg / L in SBR reactor (3), ORP=-150~-250mv, pH=6.5-7.5, water filling ratio is 0.6, reaction time is 2-2.5h; The liquid enters the intermediate water tank (9) through the first electromagnetic valve (8);

[0023] 2) The supernatant in the intermediate water tank (9) is pumped into the N-SBR reactor (11) through the second water inlet pump (10), the water filling ratio is 0.6, and the second aeration pump (13) is turned on for aeration. Oxygen nitrification, control DO=4-6mg / L, aeration 3-4h, after nitrific...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com